11 |

P a g e

STEP 3.1

ROOF ASSEMBLY

3.1 - ASSEMBLY PARTS

–

ROOF ASSEMBLY

PART CODE QTY

DESCRIPTION

L

1

1970mm L flashing

C

1

1970mm C channel

ST

8

Self-tapping screw

3.1 - ASSEMBLY

–

ROOF ASSEMBLY

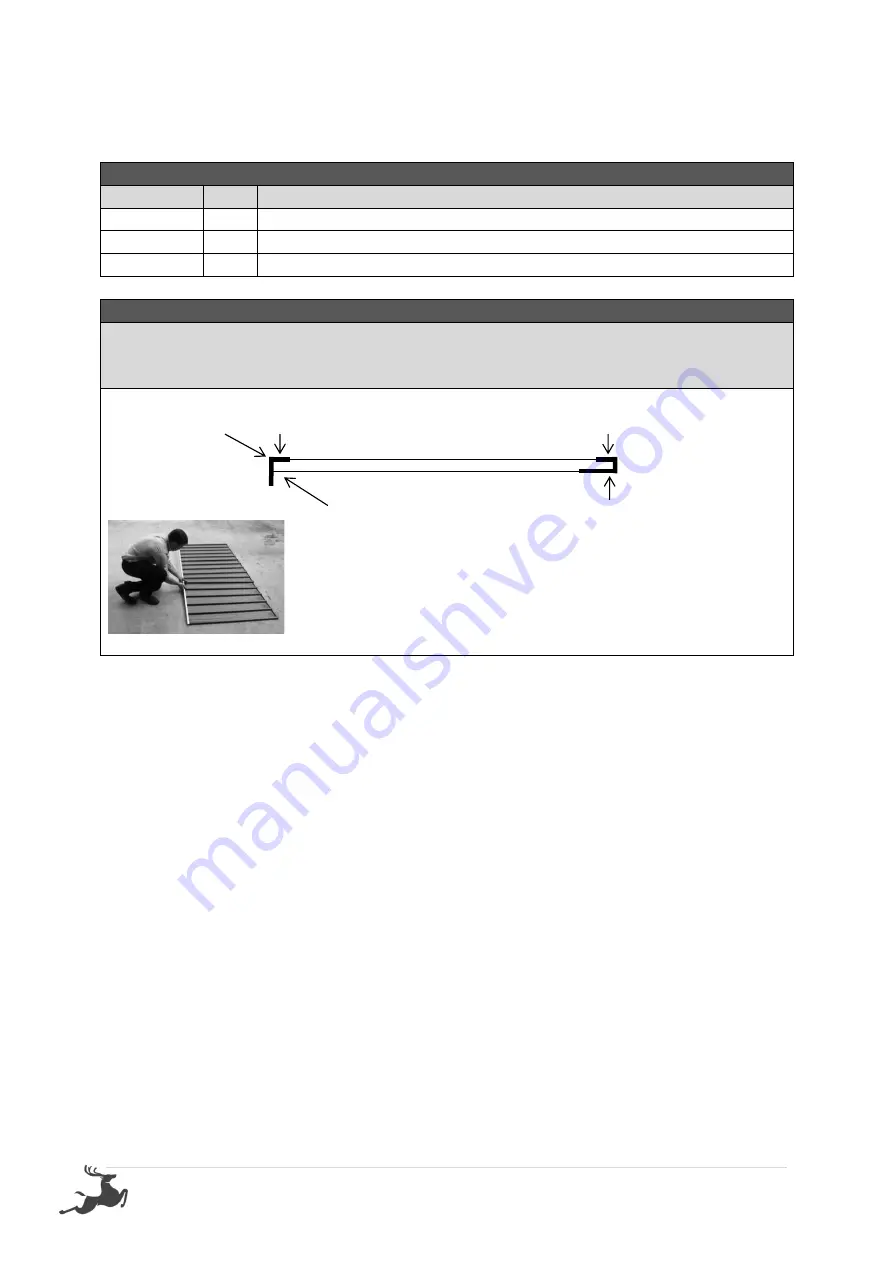

Place L on RS (Roof Sheets) as shown in picture. Screw through top, 1 Rib in from each end

and into each join of sheet (4 times all up) using ST x 4.

Slide C into place and repeat process.

Screw

Screw

Back

Front

Bent up edge

L

C

Summary of Contents for Birch 6x3

Page 19: ...18 P a g e ...