8 |

P a g e

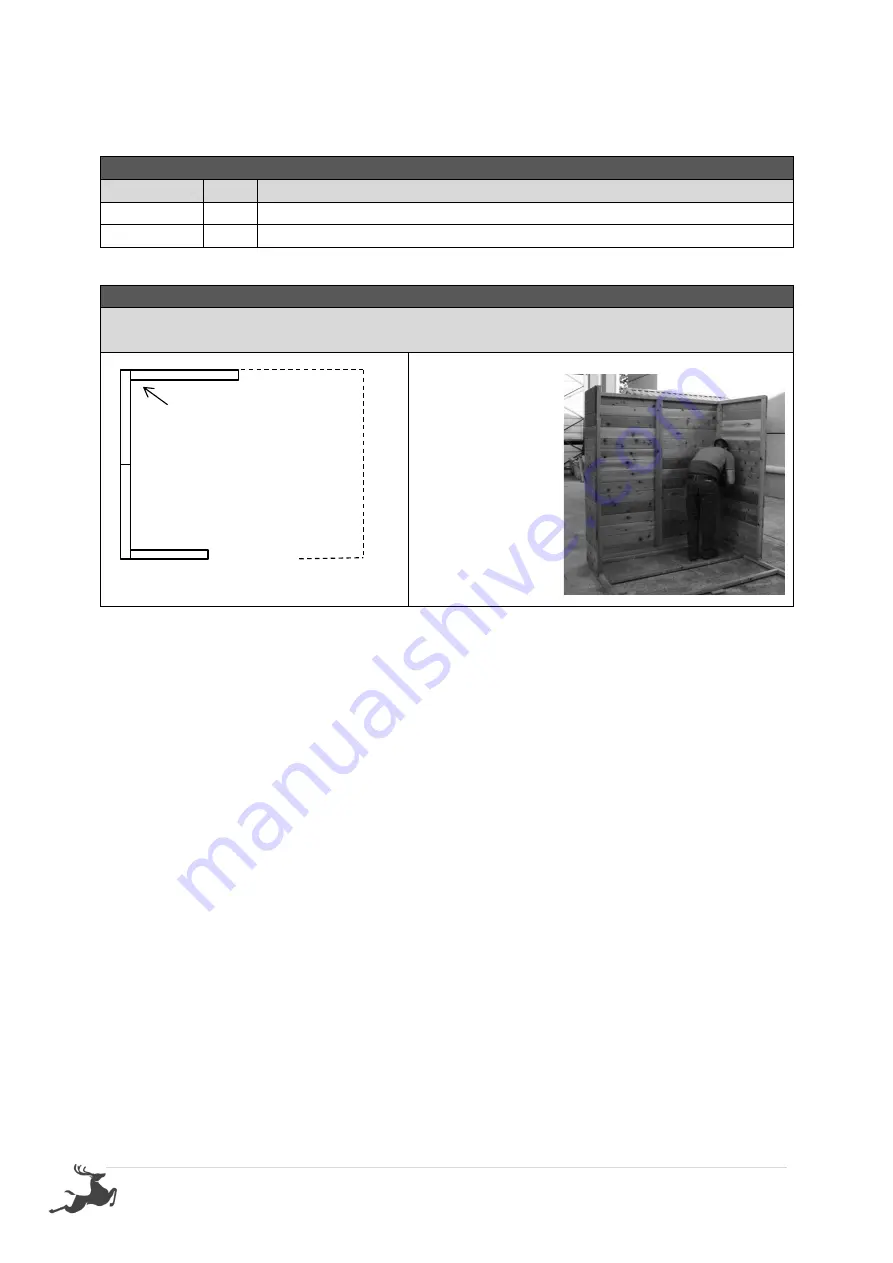

STEP 2.2

WALL ASSEMBLY

2.2 - ASSEMBLY PARTS

–

WALL ASSEMBLY

PART CODE QTY

DESCRIPTION

P

1

1200mm Wall panel

65HHS

3

65mm Hex head screw

2.2

- ASSEMBLY

–

WALL ASSEMBLY

Screw through P into P (Top, centre & bottom) using 3 x 65HHS, holding studs flush on the

outside

.

P

Screw 3 x 65HHS (Top,

centre & bottom)

FRONT OF SHED

P