© stilum GmbH, Gewerbegebiet Larsheck, D-56271 Kleinmaischeid • Tel. +49 (0) 2689 92790-0 • All rights and product modifications reserved.

Mounting instructions for swing „patis 3“ robinia

Item-No. 51 2013 601

State: 10.09.2020 p. 3

7. Align the play equipment on the foundation and screw it by using the included

heavy-duty dowels.

8. Cover the entire impact area with fall protection according to the required

drop height in accordance with EN 1176-1.

Critical drop height: 1400 mm

Recommended surface material: sand, wood chips, gravel,

synth. impact protection.

With a smaller installation depth (special edition) we recommend synthetic

impact protection. In this case, make sure that protruding parts (e.g. screws,

gusset plates) are covered with appropriate fall protection.

9. Screw the chains with the swing seats onto the swing suspension.

10. Do not allow children to use the equipment before the installation has been

finished.

Attention:

If the play equipment has been incompletely installed or partly dis-

mantled when carrying out maintenance and repair work, this may lead to par-

ticular risks of injury for the user. For this reason, make clearly visible that the

equipment shall not be used in such cases.

STAINLESS STEEL

NOTE:

Play equipment, which contain components made of stainless steel

should not come with „normal“ steel parts in contact. Those steel parts may rub

off and leave small steel particles in combination with moisture brown rust stains.

MAINTENANCE:

If such corrosion occur on stainless steel parts, they are fine to

remove with an abrasive (240 grit).

Please take care when transporting and setting up the fact that the components

are made of stainless steel with no „normal“ steel parts in contact.

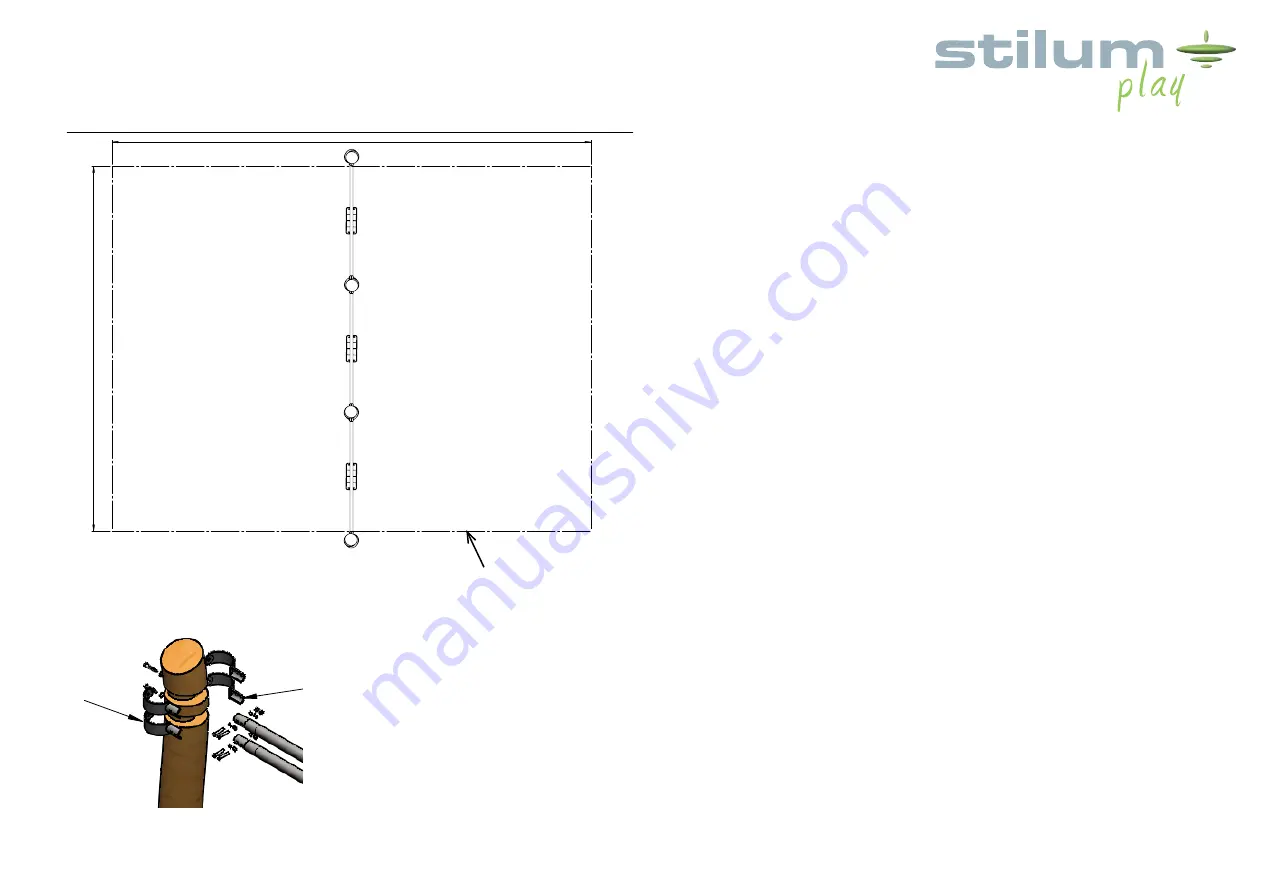

Diagram 3: Top view

Area of the minimum space =

Impact surface when using natural floors with a

shock-absorbing effect.

When using synthetic impact protection the impact area

shortens in the direction of the swing by 500 mm each.

The minimum space remains preserved in its entirety.

7800

5940

OHNE SCHRIFTLICHE ZUSTIMMUNG DER KAISER GMBH DARF DIESE

TECHNISCHE UNTERLAGE WEDER VERVIELFÄLTIGT, NOCH DRITTEN MITGETEILT ODER

ZUGÄNGLICH GEMACHT WERDEN, NOCH IN SONSTIGER WEISE MISSBRÄEUCHLICH VER-

WENDET WERDEN. ZUWIDERHANDLUNGEN WERDEN URHEBERRECHTLICH VERFOLGT.

1

patis 3 Robinie

Benennung

Gepr.

Blatt

Datum

Projekt

Gez.

Zeichnungsnummer

Rev

Änderung

Datum

1:30

A3

Name

Name

Draufsicht

0512-00-00

Maßstab

Mattheis

14.03.17

a Mindestraum angepasst

24.05.17 DB

Gewerbegebiet Larsheck

56271 Kleinmaischeid

Deutschland

2

8

10

7

1

3

15

6

4

16

12

13

14

12

11

9

5

Pos. Stck

Typ

Benennung

Abmessung

Werkstoff

ZeichnNr

Bemerkung

Gewicht

1

2

HT

Schaukelpfosten

Ø200x2613

Robinie

0510-01-01

46.93

2

1

BG

Schaukelaufhängung

1930x232x48,3

0510-02-00

19.66

3

4

KT

Gewindestange

M16x170

4.6

S-0609-05-01

0.27

4

4

BG

Schelle SBG obere Lasche

213x140x60

S-05002-02-00

0.5

5

4

BG

Schelle Schweißbaugruppe untere Lasche

213x140x60

S-05002-03-00

0.5

6

2

BG

Pfostenschuh 450

250x140x808

S-05006-00-00

18.67

7

2

KT

Schaukelgelenk

35x40x83

S-07005-01-00

0.32

8

1

BG

Schaukel 1800

1800

S-09003-03

rot

3.24

9

8

KT

Linsenkopfschraube

M10x60

A2

ISO 7380

10

2

KT

Senkkopfschraube

M10x70

A2

DIN 7991

11

10

KT

Hutmutter selbstsichernd

M10

A2

DIN 986

12

18

KT

Unterlegscheibe

Ø10,5

A2

DIN 125

13

4

KT

Sechskant Holzschraube

12x70

A2

DIN 571

14

4

KT

Unterlegscheibe

Ø13

A2

DIN 125

15

8

KT

Hutmutter selbstsichernd

M16

A2

DIN 986

16

8

KT

Fixanker, Scheibe, Mutter

M16x170

verzinkt

0.28

OHNE SCHRIFTLICHE ZUSTIMMUNG DER KAISER GMBH DARF DIESE

TECHNISCHE UNTERLAGE WEDER VERVIELFÄLTIGT, NOCH DRITTEN MITGETEILT ODER

ZUGÄNGLICH GEMACHT WERDEN, NOCH IN SONSTIGER WEISE MISSBRÄEUCHLICH VER-

WENDET WERDEN. ZUWIDERHANDLUNGEN WERDEN URHEBERRECHTLICH VERFOLGT.

Oberflächen nach

DIN ISO 1302

Reihe 2

Zul. Abweichung

DIN 2768 - mH

2

patis 1 Robinie

Benennung

Gepr.

Werkstoff

Blatt

Datum

Projekt

Gez.

Zuschnitt

Zeichnungsnummer

Rev

Änderung

Datum

1:20

A3

Gewicht

Name

Name

Explosion

0510-00-00

162.3

Maßstab

Mattheis

28.02.17

Gewerbegebiet Larsheck

56271 Kleinmaischeid

Deutschland

Diagram 4: Assembly