1 of 4

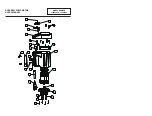

AC BARREL PUMP MOTOR

USER’S MANUAL

MODEL NUMBER

17004501 & 17004502

A. SAFETY

All safety instructions must be observed and followed.

Before Using

1. There is high speed rotating components. Failure to follow the safety instructions may lead to serious injury. All safety instructions must

be observed and followed strictly.

2. Before installing and starting the barrel pump, the related engineer must have the considerable qualification and is familiar with this manuals.

3. The installation and maintenance must according to the current machinery and electrical standard strictly.

4. The spare parts life time will be limited by wear and corrosion. The failure is affected by operating environment. The user has the

responsibility to operate in accordance with the regulations. The regular maintenance and spare parts change should be performed

regularly. Stop the pump when the pump under irregularity and obviously dangerous status.

5. The pump should install the detection alarm system when it was installed at the location where may cause the failure or personal injury.

Using

1. Wear protective clothing, goggles and in accordance with the safe production routine when operate the corrosive and hazardous substance.

2. It is prohibited to use plastic or aluminum alloy pump pipe and the non-explosion proof motor when transferring the flammable liquids.

3. Carry flammable liquids, the earth wire must be installed, electrostatic protection device and conductive hose must be used when

transferring the flammable liquids.

4. Make sure the pump head insert to the liquids completely before using. Also all the connectors connect tightly. Without leakage and fall

out dangerous situation.

5. The suitable flexible pipe must be used during transferring high temperature liquids.

6. Attention to the pumped liquids temperature, viscosity and density do not exceed the stated upper limit.

7. Install the filters in the pump tube bottom when transport the liquids with impurity or solids. To avoid the blocking, please check and

clean it regularly.

8. Make sure the motor under close status before power on. Never leave the pump unattended and never operate the motors without pump.

9. Do not touch the tube bottom after switching on the electric or air source. The impeller under high speed rotating may lead to

equipment damage and personal injury.

Make sure the pump tube working under vertical position. Never upend or lay flat after using. Pay attention to the residual liquids may

lead to injury or cause environmental damage.

PUMP MODEL

17004501

17004502

ELECTRICAL POWER

Current

AC

AC

Voltage(V)

230

120

Power (W)

450

450

Load Speed

(RMP)

Rated Speed

(RMP)

3000~11000

3000~11000

20000

20000

B. MACHINE DESCRIPTION

MOTOR:

AC series motor with the overheating protection components, Quick coupling adapter, Automatic positioning coupling and

Adjustable speed switch.

ATTENTION!

• Never operate the motors without pump.

• Never leave the pump unattended.

• Never run dry of the pump.

• The pump should not be immersed deeper into the liquid than the outlet connection.

C. TECHNICAL DATA

C1. Electrical Data

D. OPERATING CONDITIONS

D1. Environmental Conditions

Electro-Motor operating environment: -25~40˚C

D2. Power Supply

Make sure that the supply voltage corresponds to the voltage indicated on the rating plate.

ATTENTION!

Power from lines with values outside the indicated limits can damage the electrical components.