5 | Installation

10/2019 | ID 443150_en.00

41

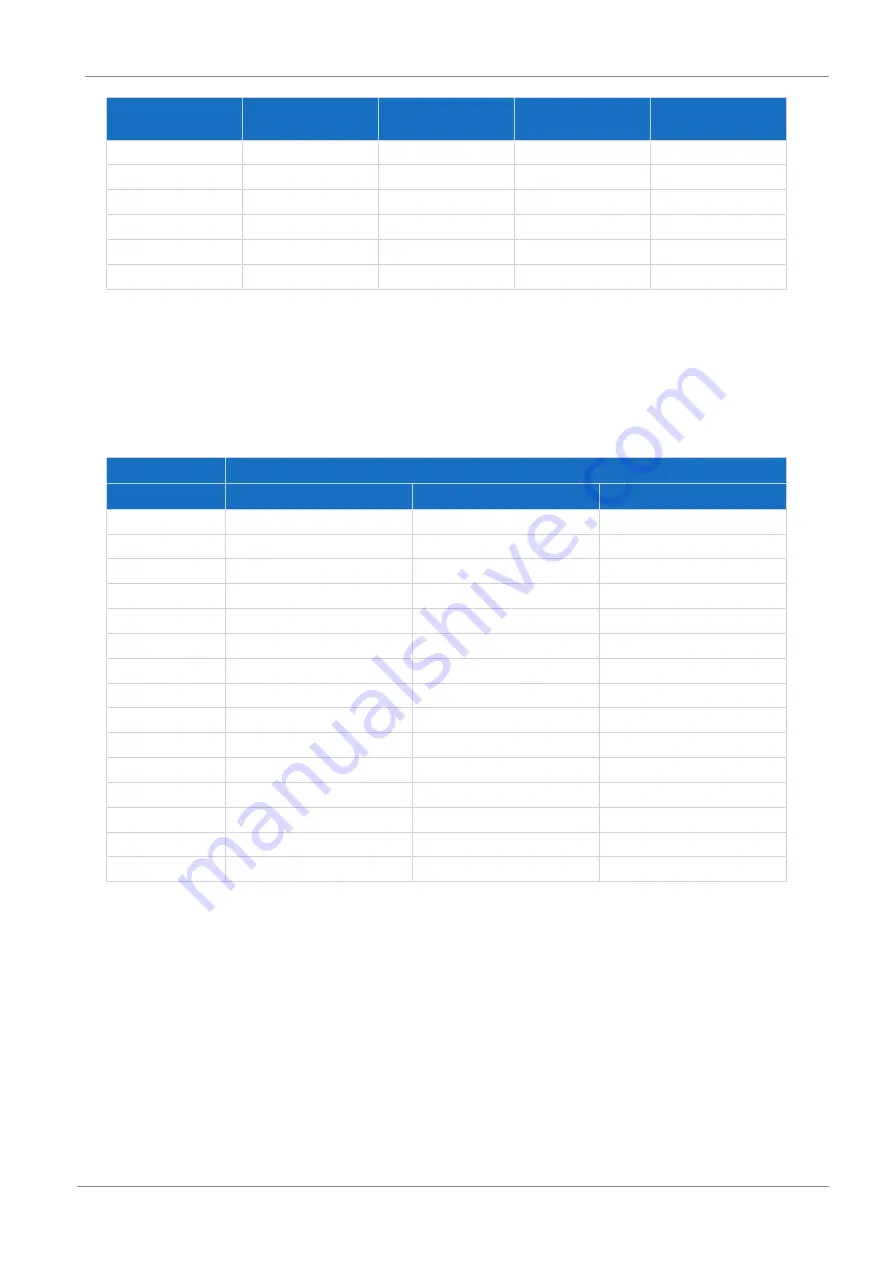

Gear unit type

Number of screws

Screw size

Min. screw-in depth

[mm]

Strength class

KL102_G

4

M6

11

10.9

KL202_G

4

M6

11

10.9

KL102_F

4

M8

–

10.9

KL202_F

4

M8

–

10.9

KL102_NG

4

M6

–

10.9

KL202_NG

4

M6

–

10.9

Tab. 18: Information on screws for mounting the gear unit housing on the machine

5.5

Tightening torques

Note that the following tightening torques apply to screws that are used for mounting the motor on the gear unit or the

gear unit on the machine. For clamp couplings, clamping screws of shrink rings and other connection elements, other

tightening torques apply that are specified in the specific context.

Tightening torque M

A

[Nm]

Thread

Strength class 8.8

Strength class 10.9

Strength class 12.9

M4

3.3

4.8

5.6

M5

6.5

9.5

11.2

M6

11.3

16.5

19.3

M8

27.3

40.1

46.9

M10

54

79

93

M12

93

137

160

M14

148

218

255

M16

230

338

395

M18

329

469

549

M20

464

661

773

M22

634

904

1057

M24

798

1136

1329

M27

1176

1674

1959

M30

1597

2274

2662

M36

2778

3957

4631

Tab. 19: Tightening torques for screws with metric standard thread in accordance with DIN 13-1 (coefficient of friction µ

ges

=

0.14).