4. OPERATING AND ADJUSTING HOOK UNIT

After attached hook unit to mainframe, turn handle (No.6) backward, loosen nut M16 (No.11), Take allen

wrench,and insert the hole of the hexagon socket screw(No.12),then turn hexagon socket screw (No.12) , so that

the distance between slide block(No.13) and hook frame can be adjusted , to fit with object’s thickness , to clamp

the object ,then tighten nut M16.

Turn handle (No.6) backward, Moving hook to appropriate position, Turn handle forward, the object can be

clamped and can be moved.

5. DRIVING SMART TOW TRACTOR

1) Speed knob.

Speed and acceleration are freely programmable.

To operate the smart tow tractor moving forward or backward . turn the butterfly speed knob clockwise or counter

clockwise gently and smoothly .

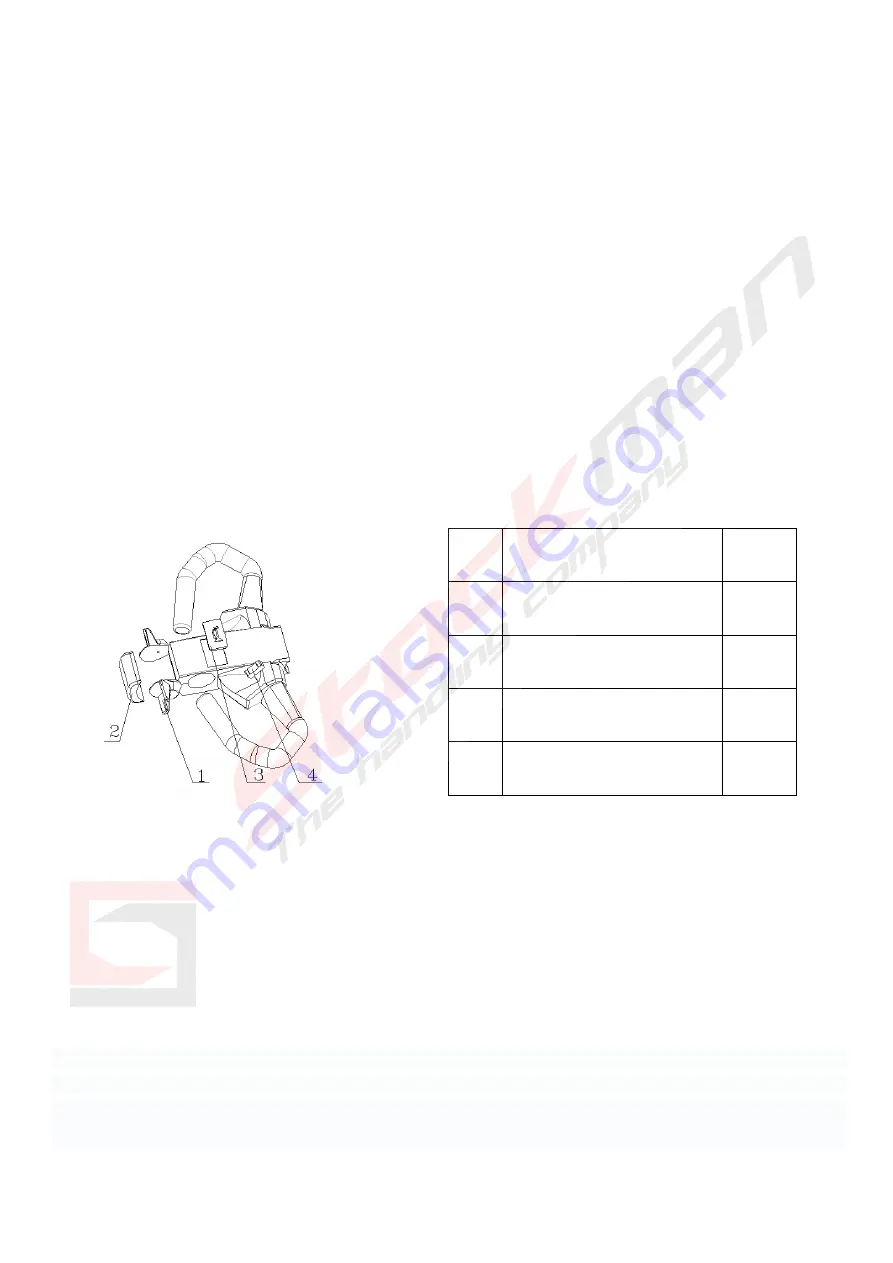

FIG 3

2) Safety emergency switch (No.2 , fig 3)

The safety emergency switch prevents you from getting squeezed between the smart tow tractor and the obstacle .

When you push it , the smart tow tractor will stop.

3) Horn

4)High and slow speed switch .

This button allows you to freely switch fast and slow.

Handle unit (No.1 and No.2,fig

5)Pull locating stud (No. 4) out locating plate (No. 2), and turn handle unit to appropriate position, then insert

locating stud into locating plate.

No.

Description

Quantity

1.

Speed knob

2

2.

Safety emergency switch

1

3.

Horn button

1

4.

High and slow speed switch

1