20

20 i-CON Calibration (Page 1 of 2)

You will need a suitable container to collect the product or seed when calibrating, and an accurate set of

scales which weighs in grams

At the machine

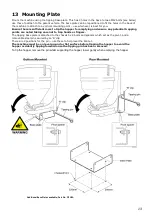

1. Fit the calibration hopper and feed block assembly (see page 19)

2. Position a suitable collection tray directly underneath the calibration hopper to catch the product

3. Place a few kilograms of seed in the hopper

At the ICON instrument

1. Switch the spinning disc off at the instrument (see page 16)

2. Switch the head unit ON via the left hand side push

button – wait until the start-up routine has finished

and displays the main “home screen”

3. Scroll through

to the Setup Menu and select the

Applicator Icon

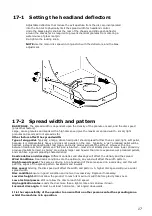

4. Adjust the implement width accordingly - refer to the

RDS manual, page 25, section 3.3, Set Implement

Width

5. Ensure the correct application rate is

entered – select and adjust accordingly,

refer to the RDS manual, page 21, section 3.1, Setting the Application Rate

6. Ensure the feed roller setup is appropriate for the intended product or seed type, application rate and

forward speed range for application

7. The instrument calculates the calibration factor from the working width, target application rate, and the

metered weight delivered whilst calibrating. If however as a result of the calibration routine, you find that

you cannot achieve your desired field speed, displayed in the top right corner of the screen, then

re-configure the feed roll assembly and repeat the calibration procedure

8. Prime the feed rollers with product by pressing and holding briefly the prime button on the junction box

- this will ensure a higher initial calibration accuracy, empty the contents of the tray back into the hopper

9. For an

Auto Calibration

from the Product Setup page, touch

10. Touch

and enter the quantity that you wish to dispense for calibration purposes. You can enter

the quantity in grams if preferred. The CAL factor will however, still be calculated in kg/rev

11. Touch on the screen page

12. After

the key the motor runs at the calibration speed (calculated from the Simulated Forward

Speed, Width, Application Rate and current calibration factor)

13. The dispensed weight (based on the current calibration factor) is displayed

14. Weigh the product dispensed and then enter the measured weight, and press

15. A new calibration factor is then re-calculated and displayed

16. Your in field min and max speeds will be displayed as per the image to the right hand side. If you find

that you cannot achieve your desired field speed, then re-configure

the feed roller assembly and repeat the calibration procedure

(see page 18 for more details)

17. Touch to save the new factor, it is advised to repeat the

calibration 2 more times to ensure accuracy