Page 9

Due to continuous product research and development,

the information contained herein is subject to change without notice.

www.stoddart.com.au

www.stoddart.co.nz

• All Gastronorm pans and extra dividers are sold separately

• Each module can hold one 1/1 pan, two 1/2 pans, three 1/3 pans, four 1/4 pans, six 1/6 pans and nine 1/9 pans. Pan depths are 25mm,

65mm, 100mm and 150mm. Contact your distributor about the best possible depth for the product you intent to display

• For 1/6 and 1/9 Gastronorm pans, extra dividers are required

4.1.3 Gastronorm Pans

• All food MUST be pre-heated/cooked before placing in the unit. Attempting to cook food with this unit can lead to food poisoning

• Ensure the well is maintaining the food temperature over 65°C

• The temperature reached on the temperature gauge is the air temperature, NOT the food temperature

• It is important to regularly monitor the food temperature in the unit

4.2.1 Food Temperature

• All storage of food should comply with local health standards and regulations

• All pans should be cleaned and placed in night storage. No pans should be left in the unit

• This unit is NOT designed to store product after hours. The unit MUST be switched OFF

• If the unit is moved for night storage, ensure the castors are locked (mobile units only)

4.2.2 Food Storage

4.2 Food Safety

• Fill the three removable water wells (located in-between the elements) with water, approximately 6mm from the top

• Place the GN pans in the unit, ensure there are no gaps

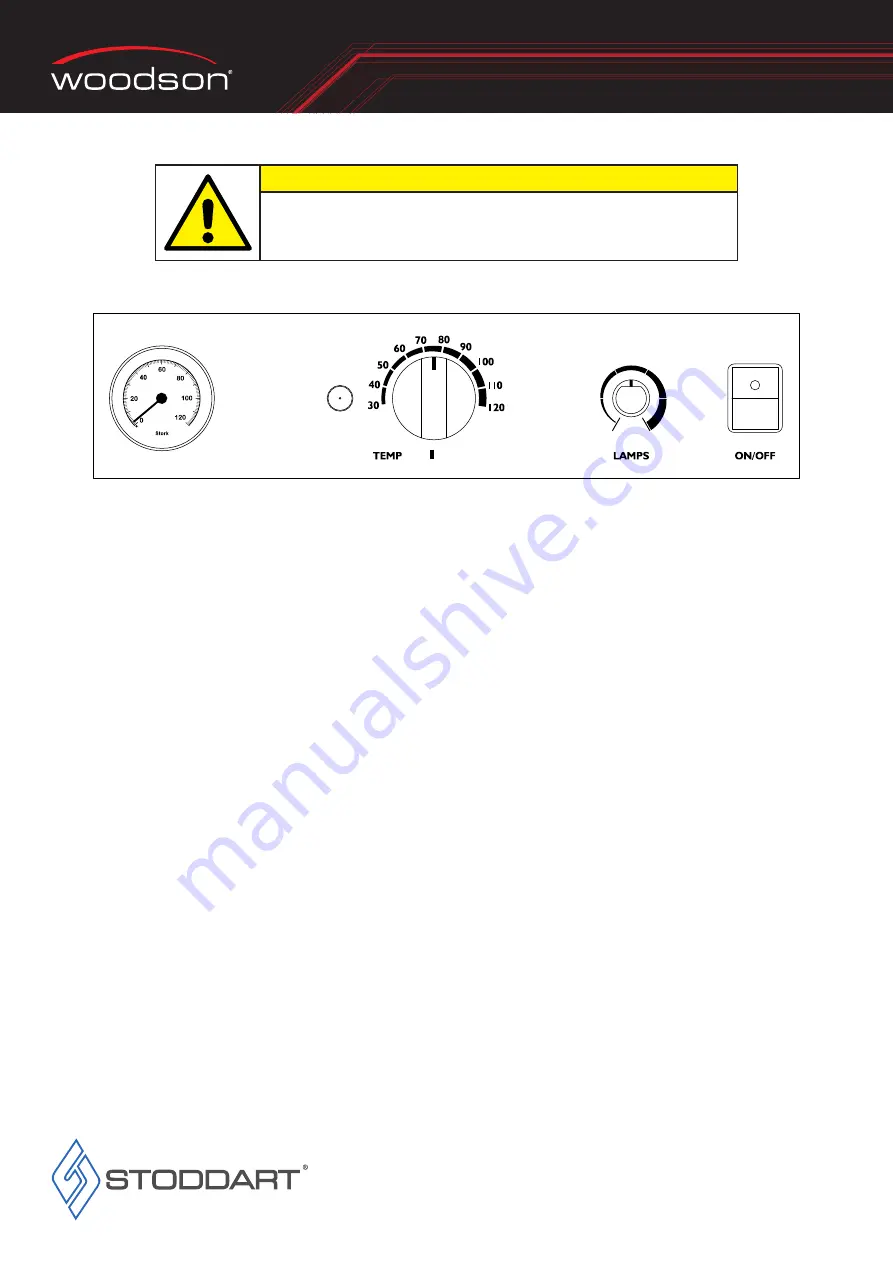

• Switch unit ON and turn the temp dial to 70°C - 90°C. Adjust the lamp dial to approximately 80%. (adjust both dials accordingly if

required). Close the doors and heat for 45 minutes

• Once unit has reached temperature, place the cooked product into the GN pans. All food placed in the unit MUST be pre-heated/cooked

• Close the doors

IMPORTANT

This unit is not designed to cook products, it only maintains

them above the regulated 65°C serving temperature.

4.1.2 Operation

4.1.1 Control Panel

4.1 Initial Start-up & Operation

4.0 Operation