15

3.5 SANITIZING THE FREEZER AND FREEZER

PARTS

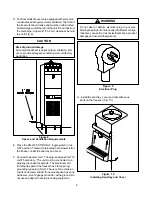

After the freezer parts have been soaked and washed in

warm, soapy water, they should be rinsed thoroughly in

clean water.

All parts must be sanitized before assembling with a

USDA certified food grade sanitizing solution (50 parts per

million of free available chlorine or equivalent is accept-

able).

A. Mix a sanitizing solution of 50 parts per million to

sanitize all loose parts before assembling.

B. Place all loose parts in this solution, then remove

and let air dry.

C. Using this sanitizing solution and the brushes pro-

vided, sanitize the product cylinder and product

outlet by dipping the brush in the sanitizing solution

and scrubbing these areas.

D. After assembling the freezer (Section 3.6), mix approx-

imately 3 gallons (11.3 liters) of sanitizing solution and

pour into the product cylinder. Brush the walls of the

cylinder above the divider plate, with brushes provided

to sanitize this reservoir area.

E. Set the STIRRING ONLY-OFF-STIRRING &

FREEZING switch in the STIRRING ONLY position

and allow to stir for five minutes. Drain the solution

in the same manner as draining the product.

F. Pour approximately one pint (1/2 liter) of mixed

neutral base into the product cylinder. Wait one minute,

then drain the neutral base and remaining sanitizing

solution through the drain spigot.

Sanitizing must be done after the freezer is clean and just

before the product cylinder is filled with mixed neutral

base. Sanitizing the night before is not effective. However,

you should always clean the freezer and parts after use.

WARNING

The United States Department of Agriculture and the

Food and Drug Administration require that all cleaning

and sanitizing solutions used with food processing

equipment be certified for this use.

When sanitizing the freezer, refer to local sanitary regula-

tions for applicable codes and recommended disinfecting

products and procedures. The frequency of sanitizing

must comply with local health regulations.

CAUTION

Avoid prolonged contact of sanitizer with freezer parts.

Prolonged contact of sanitizer with freezer may cause

corrosion of stainless steel parts.

3.6 ASSEMBLY OF FREEZER

To assemble the freezer and freezer parts, refer to the

following steps:

NOTICE

Petro-Gel sanitary lubricant or equivalent must be used

when lubrication of parts is specified.

NOTICE

The United States Department of Agriculture and the Food

and Drug Administration require that lubricants used on

food processing equipment be certified for this use. Use

lubricants only in accordance with manufacturers instruc-

tions.

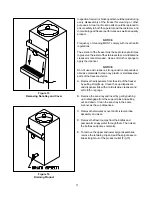

A. Assemble the divider plate and agitator assembly as

follows:

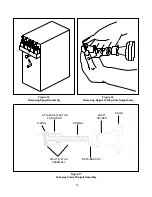

1. Before installing the drive shaft, lubricate the

bottom with Petro-Gel or any other type of sanitary

lubricant. Enough

lubricant must be applied to

create approximately a 1/8 inch bulge at the bottom

of the drive shaft (Fig.24).

Figure 24. Lubricating Drive Shaft

PETRO-GEL

Summary of Contents for 100CA

Page 1: ...Model 100FA 100CA 2217GA OPERATORS MANUAL Manual No 513653 Mar 2010...

Page 2: ......

Page 14: ...8...

Page 26: ...20...

Page 28: ...22...