16

2. Install the drive shaft into the center post by

rotating and pressing down lightly on the shaft until

the shaft drops down and engages with the gear

box shaft.

3. Replace the plastic lower bushing to the bottom of

the vertical center post.

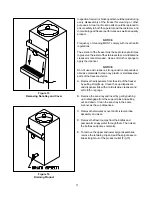

4. Assemble the divider plate to the stationary fingers.

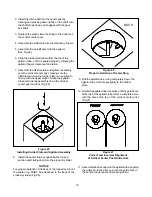

5. Assemble the anti-lift disc onto the agitator

(See Fig.23).

6. Slide the divider plate down from the top of the

agitator tube, until it is seated properly, allowing the

agitator fingers clearance for rotation.

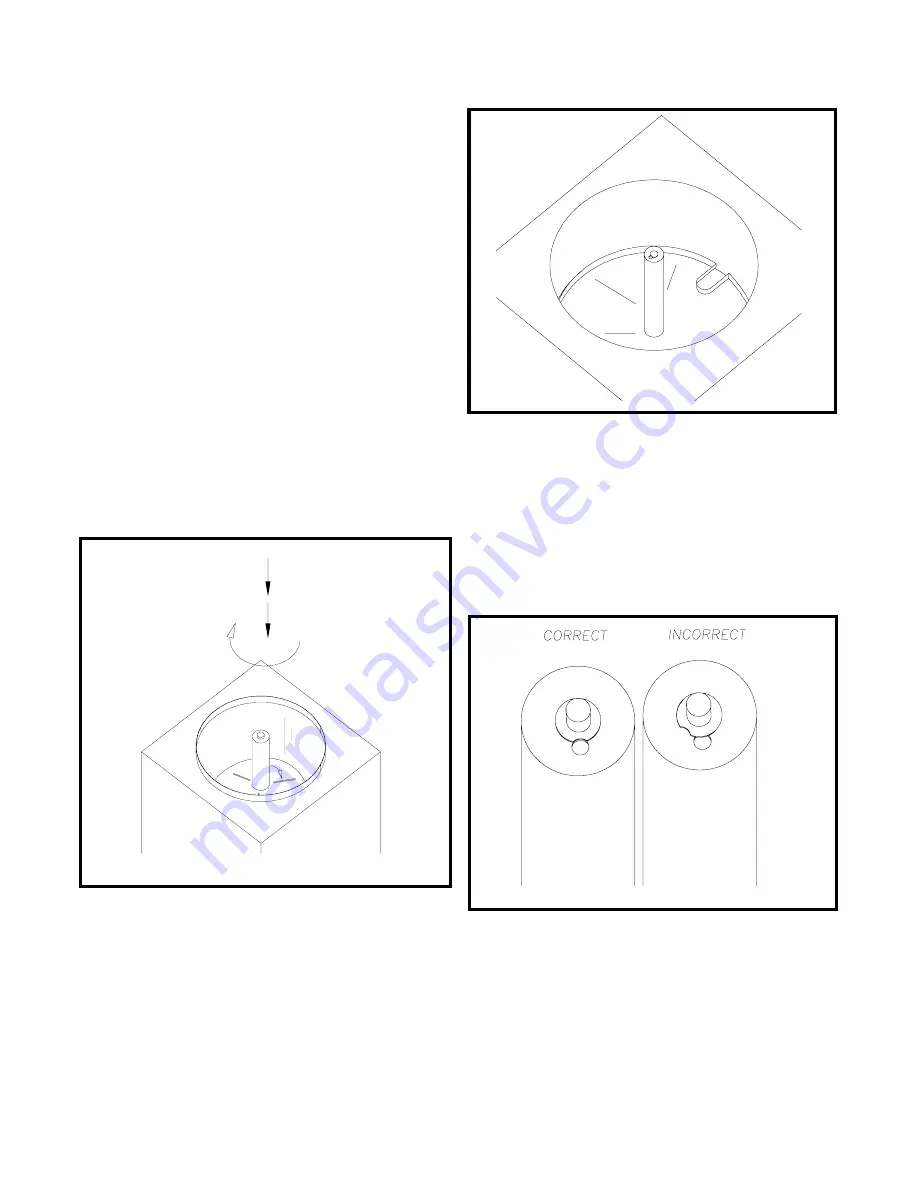

7. Assemble the divider plate and agitator assembly

onto the vertical center post, making sure the

indicator arrow on the divider plate is in position to

line up with the upper spigot. Grasp the agitator

tube and slide the assembly down the vertical

center post and lock (Fig. 25).

Figure 25

Installing Divider Plate and Agitator Assembly

8.

Install the sealer ring by squeezing the looped

section and sliding down into the product cylinder.

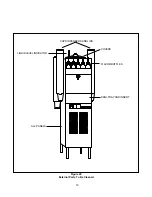

NOTICE

For proper operation of the freezer, the looped section of

the sealer ring MUST be positioned to the back of the

product cylinder (Fig.26).

BACK

Figure 26

Proper Installation of Sealer Ring

9. Roll the agitator tube o-ring completely down the

agitator tube until it seals tightly to the divider

plate.

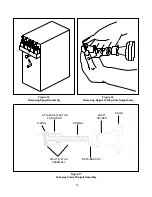

10. Rotate the agitator tube clockwise until the guide hole

at the top of the agitator tube forms a complete circle

with the hole at the top of the vertical center post

(Fig.27).

Figure 27

Correct and Incorrect Alignment

of Vertical Center Post Guide Hole

11. Assemble the drive cap onto the agitator tube, aligning

the guide pin in the drive cap with the guide hole in

the vertical center post and pressing down.

Summary of Contents for 100CA

Page 1: ...Model 100FA 100CA 2217GA OPERATORS MANUAL Manual No 513653 Mar 2010...

Page 2: ......

Page 14: ...8...

Page 26: ...20...

Page 28: ...22...