17

SECTION 4

MAINTENANCE INSTRUCTIONS

4.1

PREVENTIVE MAINTENANCE

It is recommended that a preventive maintenance

schedule be followed to keep the freezer clean and

operating properly. The following steps are suggested

as a preventive maintenance guide.

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE

MAIN ELECTRICAL POWER HAS BEEN

DISCONNECTED.

The United States Department of Agriculture and the

Food and Drug Administration require that lubricants

used on food processing equipment be certified for this

use. Use lubricants only in accordance with the

manufacturer’s instructions.

A.

DAILY

1.

The exterior should be kept clean at all times

to preserve the luster of the stainless steel. A

mild alkaline cleanser is recommended. Use a

soft cloth or sponge to apply the cleanser.

2.

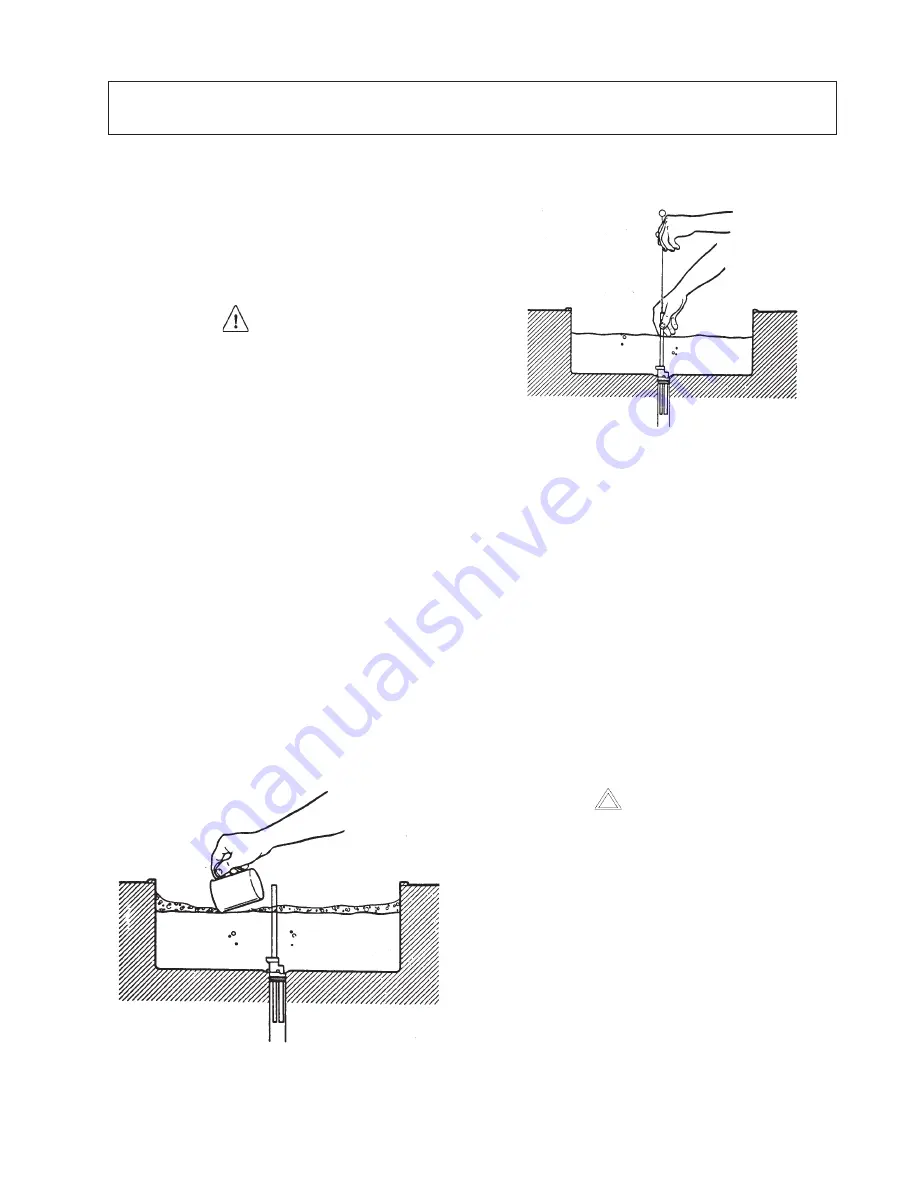

Using a sanitized one-pint aluminum overrun

container, skim the mix in the hopper to remove

any foam buildup (Fig. 31).

Figure 31. Skimming Hopper

3.

Run a sanitized brush down mix inlet regulator

(carburetor) tubes (Fig. 32).

NOTE

When sanitizing, the skimmer, brush and the hand

that holds the mix inlet regulator (carburetor) must

also be sanitized.

4.

Note any unusual noises or operating

conditions upon startup. Repair or rectify

immediately if problems exist.

NOTE

Do not use acid cleaners, strong caustic

compounds or abrasive materials to clean any

part of the freezer exterior or plastic parts.

CAUTION

INSPECTION FOR WORN OR BROKEN PARTS

SHOULD BE MADE AT EACH DISASSEMBLY

OF THE FREEZER.

B.

WEEKLY

1.

Check all “O” Rings for excessive wear and

replace if necessary.

2.

Check scraper blades, front bearing and rear

bearing for wear damage (paragraph 3.8).

Figure 32. Sanitizing Mix Inlet Regulator

(Carburetor)