Owner’s Manual #513613

8

E112/F112 Model Machines

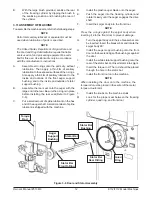

B. CLEAN-OFF-ON

Switch

The CLEAN-OFF-ON switch is used to supply

power to the control circuit. When the switch

is in the OFF (middle) position, power will not

be supplied to the control board or refrigeration

system. When the switch is in the ON position,

the machine will operate in the freezing mode.

When the switch is in the CLEAN position, all

refrigeration will stop and the auger will start

rotating.

C.

ADD MIX Light

The ADD MIX light will fl ash to alert the operator

to a low mix condition. It does so by monitoring

the mix level in the hopper. When the ADD MIX

light is fl ashing, refi ll hopper immediately.

NOTE

Failure to refi ll hopper immediately may result in

operational problems.

D. Diagnostic

Light

The Diagnostic Light will fl ash if an error occurs.

The light will fl ash once if there is a compressor

error. There will be two quick fl ashes if there is an

auger error. And there will be three quick fl ashes

if the machine is left in clean mode for more than

20 minutes. Refer to the troubleshooting section

for details.

E. Consistency

Adjustment

Screw

The Consistency Adjustment Screw increases or

decreases product consistency. A tension spring is

connected to the screw and changes the amount

of torque needed to complete a refrigeration cycle.

Turn the knob clockwise to increase consistency

or counterclockwise to decrease consistency.

NOTE

An additional spring is included with the machine

behind the header panel. The additional spring can

be installed for use with shake mixes when a higher

consistency is required. Do not use the optional

spring with slush mixes.

F.

Front Door Safety Switch

The front door safety switch prevents the auger

from turning when the front door is removed. The

switch is open when the door is not in place and

closed when the door is properly installed.

G. Autofi ll Kit - Optional (E112 Part 2183807, F112

Part 2187101)

The

autofi ll kit is used with a pump to keep the

hopper fi lled. The autofi ll kit is for use with non-

potentially hazardous food substances; non-dairy.

Refer to Section 5-4 for Autofi ll options.

H.

Light Kit - Optional (E112 Part 2183800, F112

Part 2187102)

The light kit is installed behind the header panel

and illuminates a translucent header panel.

I.

Bottle Rack Kit - Optional (E112 Part 2187100,

F112 Part 2187040 or 2187024)

The bottle rack kit is installed onto the header

panel and holds 7 fl avor bottles (13 bottles on

the 2187024).

J.

Spinner Kit - Optional (E112 Part 2187103,

F112 Part 2187031)

The spinner kit is installed on the front of the

machine and offers blended frozen beverages.

3.3 SANITIZING

Sanitizing must be done after the machine is cleaned and

just before the hopper is fi lled with mix. Sanitizing the night

before is not effective. However, you should always clean

the machine and parts after each use.

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food

processing equipment be certifi ed for this use.

When sanitizing the machine, refer to local sanitary regu-

lations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations.

Mix sanitizer according to manufacturer’s instructions to

provide a 100 parts per million (ppm) strength solution and

check the solution with chlorine test strips. Mix sanitizer

in quantities of no less than 2 gallons (7.5 liters) of 90°

to 110°F (32° to 43°C) water. Allow sanitizer to contact

the surfaces to be sanitized for 5 minutes. Any sanitizer

must be used only in accordance with the manufacturer’s

instructions.

In general, sanitizing may be conducted as follows:

A.

Prepare Stera-Sheen Green Label Sanitizer

or equivalent according to manufacturer’s

instructions to provide a 100 ppm strength solution.

Mix the sanitizer in quantities of no less than

2 gallons of 90° to 110°F (32° to 43°C) water.

Check the strength of the sanitizing solution. Use

a chlorine test strip and color chart to make sure

the solution has 100 ppm. Any sanitizer must be

used only in accordance with the manufacturer’s

instructions.

CAUTION

Do not allow sanitizer to remain in contact with

stainless steel parts for prolonged periods. Pro-

longed contact of sanitizer with machine may cause

corrosion of stainless steel parts.