Owner’s Manual #513613

12

E112/F112 Model Machines

B.

With the large brush provided, sanitize the rear

of the freezing cylinder by dipping the brush in

the sanitizing solution and brushing the rear of

the cylinder.

3.11 ASSEMBLY OF MACHINE

To assemble the machine parts, refer to the following steps:

NOTE

Petrol Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specifi ed.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubri-

cants used on food processing equipment be certi-

fi ed for this use. Use lubricants only in accordance

with the manufacturer’s instructions.

A.

Assemble all o-rings onto the parts dry, without

lubrication. Then apply a thin fi lm of sanitary

lubrication to the exposed surfaces of the o-rings.

Also apply a thin fi lm of sanitary lubricant to the

inside and outside of the front auger support

bushing, and to the inside and outside of stator

support bushing.

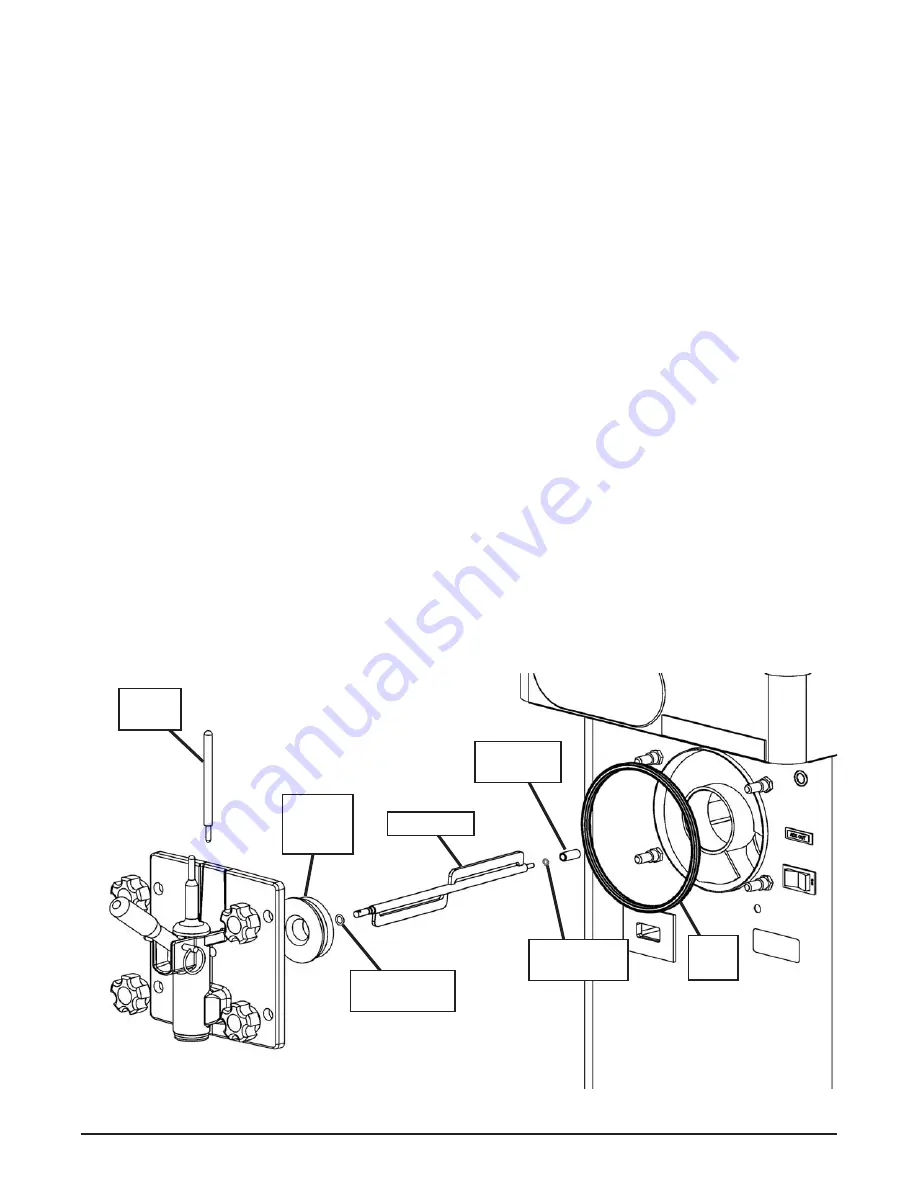

B.

Assemble the rear seal onto the auger with the

large end to the rear. Be sure the o-ring is in place

before installing the rear seal (Refer to Figure

3-8).

C.

Put a small amount of spline lubricant on the hex

end of the auger shaft. A small container of spline

lubricant is shipped with the machine.

D.

Install the plastic auger blade onto the auger.

E.

Push the auger into the freezing cylinder and

rotate it slowly until the auger engages the drive

shaft.

F.

Insert the spigot body into the front door.

NOTE

Press the o-rings against the spigot body when

inserting it into the front door to prevent damage.

G.

Turn the spigot body until the ice breaker bar can

be inserted. Insert the breaker bar and rotate the

spigot body 90

H.

Install the auger support bushing onto the front

door so the beveled edge of the bushing is against

the door.

I.

Install the white stator support bushing onto the

rear of the stator bar and insert stator into spigot.

J.

Insert the torque rod. The rod should be placed

through the hole in the stator bar.

K.

Install the front door onto the machine.

NOTE

When installing

the

door onto

the

machine,

the

torque rod must be placed in the center of

the

metal

torque actuator arm

L.

Install the knobs on the machine studs.

M.

Look for the proper seal between the freezing

cylinder, quad ring, and front door

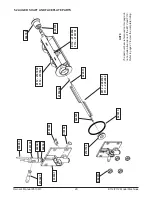

Figure 3-9 Door and Stator Assembly

Torque

Rod

Auger

Support

Bushing

Stator Bar

Front O-Ring

Stator Bar

Bushing

Quad

Ring

Stator Bar

Stator Bar

Rear O-Ring