21

3. Recover the refrigerant charge, and then leave a port

open to prevent pressure buildup when applying heat.

WARNING

BOTH SUCTION SIDE SOLENOIDS MUST BE

ACTIVATED FOR PROPER PURGING OF

SYSTEM. USE POWER CORD PART NO.

430119

OR EQUIVALENT FOR DIRECT

CONNECTION.

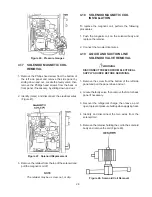

4. Remove any insulation from the T.X.V. and immediate

surrounding lines.

5. Remove or push back any foam insulation from

surrounding lines.

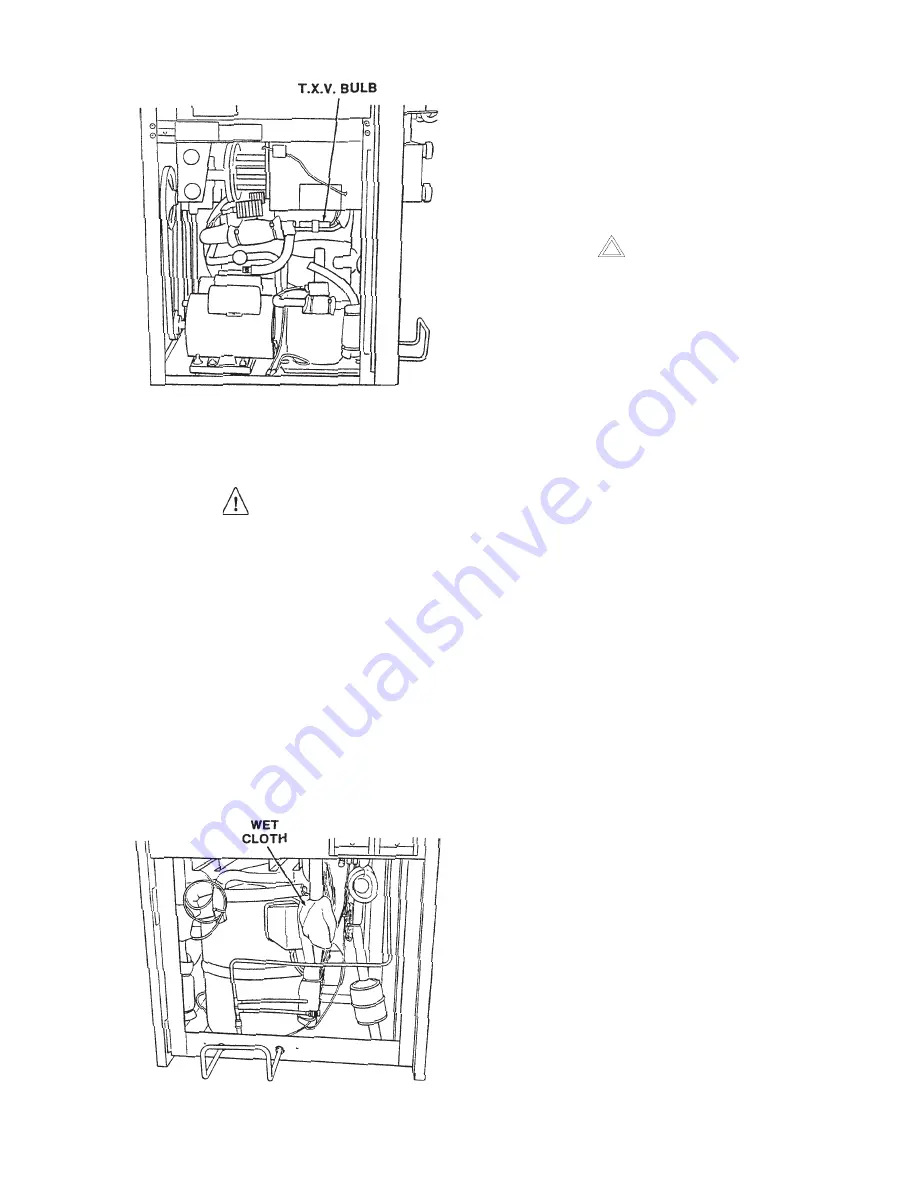

6. Apply a heatsink (wet cloth) to the valve dome (Figure

36).

Figure 35. Bulb Removal

Figure 36. T.X.V. Removal

7. Unsweat the suction line and liquid line from the T.X.V.

and remove.

4.8

T.X.V. INSTALLATION

To replace the T.X.V., perform the following proce-

dures:

CAUTION

WHEN PLACING THE T.X.V., A HEATSINK (WET

CLOTH) MUST BE USED TO PREVENT

DAMAGE TO THE VALVE.

1. Position the T.X.V. with heatsink so the liquid line and

suction line correspond with the proper valve ports.

2. Braze the liquid line and suction line to the T.X.V. by

using the appropriate brazing material.

3. Remove the heatsink from the T.X.V.

4. Replace any foam insulation to the surrounding lines.

5. Replace any insulation to the T.X.V. and surrounding

areas.

NOTE

The liquid line from the condenser is bonded to

the suction line to provide a heat exchange to help

protect the compressor from liquid slugging. This

also assures that sub-cooled liquid is being

supplied to the expansion devices.

Summary of Contents for E131G

Page 1: ...Model E131G F131G SERVICE MANUAL Manual No 513537 3 Mar 2004...

Page 2: ......

Page 14: ...6...

Page 38: ...30 Figure 51 Power Board...

Page 39: ...31 Figure 52 Program Module...

Page 54: ...46...

Page 66: ...58...

Page 68: ...60...

Page 69: ...61 666786...

Page 70: ...62...

Page 71: ...63...

Page 72: ...64...

Page 73: ...65...

Page 74: ...66...

Page 75: ...67...

Page 76: ...68...

Page 77: ...69...

Page 78: ...70...

Page 80: ......