47

SECTION 6

TROUBLESHOOTING

Troubleshooting can be difficult. The TROUBLESHOOTING INDEX

below gives a list of possible problems.

To make a repair to a problem, make reference to the cause and correction on the page indicated.

ALL REPAIRS

MUST BE MADE BY A QUALIFIED SERVICE TECHNICIAN.

This list of problems, causes and corrections will only give an indication of where a possible problem can be and

what repairs are needed. Normally, more or other repair work is needed beyond the recommendations in the list.

Remember that a problem is not normally caused by only one part, but by the relation of one part with other parts.

This list is only a guide and cannot give all possible problems and corrections. The technician must find the problem

and its source, then make the necessary repairs.

Any problem correction proceeded with an asterisk (*) may require refrigeration system repair. Refrigerant

recovery, refrigeration system repair and handling/disposal of defective refrigeration components shall be in

compliance with Environmental Protection Agency requirements per the provisions of the U.S. Clean Air Act.

In the event the Troubleshooting Guide does not help to correct the service problem, the factory Service Department

should be contacted. Contact:

STOELTING, INC.

Phone: 920-894-2293

502 Hwy. 67

Fax: 920-894-7029

Kiel, WI 53042

Problem

Subsection & Title

No.__

Problem Description

Page

6.1 Dispensing,

6.1.1

Product dispenses slowly or not at all

6-2

Servability and Overrun

6.1.2

Product is too soft

6-2

6.1.3

Low overrun

6-3

6.1.4

Mix spray when spigot is opened

6-3

6.2 Barrel and Hopper Mix

6.2.1

Hopper temperature is too warm

6-3

Temperature

6.2.2

Frozen product on hopper walls

6-4

Maintenance

6.2.3

Overnight barrel meltdown did not occur

6-4

6.2.4

Overnight barrel temperature is too warm

6-4

6.3 Electro-Mechanical

6.3.1

Freezer starts immediately after power is turned on

6-4

6.3.2

Freezer will not start after power is turned on

6-5

6.3.3

Red CLEAN light is flashing

6-5

6.3.4

HOLD READY switch will not work

6-5

6.3.5

Compressor will not start

6-5

6.3.6

Compressor will not start: hums but trips

on overload protector

6-5

6.3.7

Compressor starts, but remains on start winding

6-5

6.3.8

Compressor starts and runs, but short cycles

on overload protector

6-6

6.3.9

Compressor start capacitor open, shorted or blown

6-6

6.3.10

Compressor run capacitor open, shorted or blown

6-6

6.3.11

Compressor start relay defective or burned out

6-6

6.3.12

Compressor will not run but drive motor runs

6-6

6.3.13

Freezer refreezes too often in green light mode

6-6

6.3.14

Freezer operates too long or continuously

6-7

6.3.15

Freezer is noisy

6-7

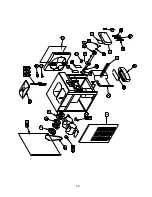

Summary of Contents for E131G

Page 1: ...Model E131G F131G SERVICE MANUAL Manual No 513537 3 Mar 2004...

Page 2: ......

Page 14: ...6...

Page 38: ...30 Figure 51 Power Board...

Page 39: ...31 Figure 52 Program Module...

Page 54: ...46...

Page 66: ...58...

Page 68: ...60...

Page 69: ...61 666786...

Page 70: ...62...

Page 71: ...63...

Page 72: ...64...

Page 73: ...65...

Page 74: ...66...

Page 75: ...67...

Page 76: ...68...

Page 77: ...69...

Page 78: ...70...

Page 80: ......