8

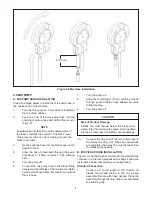

C. SPIGOT SWITCH

The spigot switch is mounted to the spigot cam assembly

behind the header panel. When the spigot is opened to

dispense product, the spigot switch opens and the “Serve

Mode” begins.

D. DISPENSE RATE ADJUSTOR

The dispense rate adjustor is located under the header

panel, to the immediate right of the spigot handle. Turning

the knob counterclockwise will decrease the dispense rate.

E. CAB OFF INDICATOR LIGHT

A fl ashing light indicates the Main Freezer Power Switch

is in the OFF position; no refrigeration is being supplied

to the cab. Place the Main Freezer Power switch in the

ON position for cab refrigeration.

F. PUMP SWITCH

The pump motor switch is the toggle switch located on the

lower part of the front panel. When the switch is placed in

the OFF position, the pump will not run. When the switch

is placed in the ON position, the pump will run until the

preset pressure is reached. It then cycles on and off as

product is drawn to maintain that pressure.

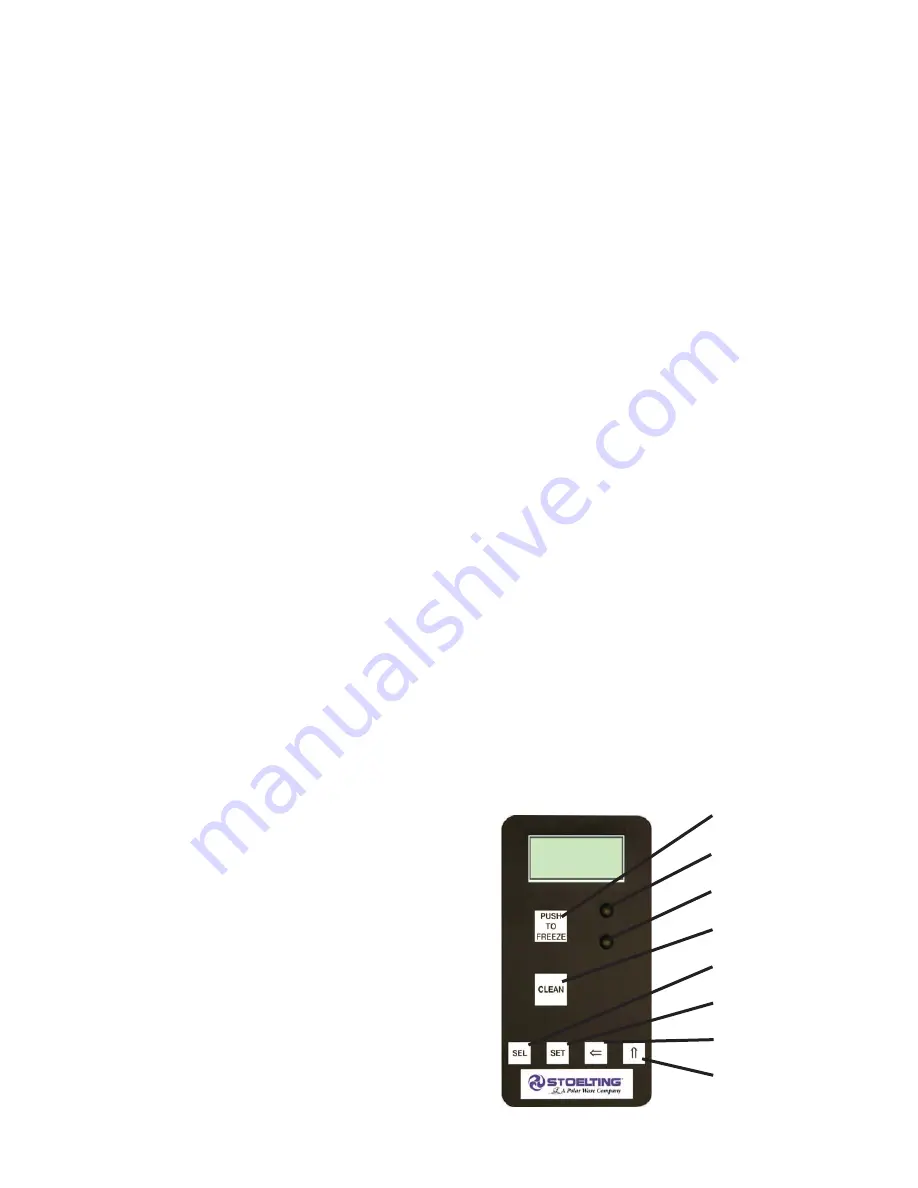

G. PUSH TO FREEZE BUTTON

The PUSH TO FREEZE button is a membrane or snap

switch used to initiate “Serve Mode”.

NOTE

After the PUSH TO FREEZE button is pressed,

the drive motor starts. After a 3-second delay, the

compressor will start.

H. LEDS

The membrane switch (touchpad) features two lights: a

green LED and an amber LED. The green LED is lit dur-

ing “Serve Mode”. During freeze down, it is not lit. When

product consistency approaches 75% in the freezing

cylinder, the green LED fl ashes. The amber LED is on

during all other modes. Both LEDs alternatively fl ash if

an error occurs or if the freezing cylinder is off.

I. CLEAN BUTTON

The CLEAN button is a membrane, or snap switch. When

the button is pressed, the freezing cycle stops and the

drive motor will start. A CLEAN message will display on

the LCD screen along with a 5-minute countdown timer.

To exit the CLEAN mode, turn the Freezing Cylinder

OFF/ON switch to the OFF position or press the CLEAN

button again. If the machine is left in CLEAN for more

than 20 minutes, an error code (E4) will be displayed on

the display panel. Place the Freezing Cylinder OFF/ON

switch in the OFF position and back in the ON position

to clear this error.

J. DRIVE MOTOR OVERLOAD

The internal drive motor overload will trip if the drive

motor is overloaded. It will reset after approximately 10-

12 minutes. If the drive motor continues to trip, refer to

Troubleshooting in Section 5.

K. MIX LOW LIGHT INDICATOR

A MIX LOW message will appear on the LCD display to

alert the operator of a low mix condition. The message

will display when there is approximately one gallon of

mix left in the mix container or when one bag of the Bag

Connection System (BCS) is empty. When the MIX LOW

message is displayed, refi ll the container or replace a

bag immediately.

L. MENU NAVIGATION BUTTONS

The Menu Navigation Buttons allow the user to display

information regarding the machine’s status of operation

as well as adjust product consistency (Fig. 3-2).

Selection Button (SEL) The SEL button is used in

combination with the up arrow button to enter into

the settings of the IntelliTec control. This button is

also used to navigate through the control settings

menu.

Set Button (SET) The SET button is used to save

a change made to the product consistency setting.

It is also used to save changes when modifying

control settings.

Left Arrow Button (

) If the left arrow button is

pressed for 5 seconds, the display will remain lit.

To turn the light off, press the left arrow button for

5 seconds. The left arrow button is used primarily

to navigate through the control settings.

Up Arrow Button (

) After pressing the SET

button, the up arrow button will change the value

of the product consistency setting. This button

is used primarily to navigate through the control

settings.

Push to Freeze

Green LED

Amber LED

SEL Button

SET Button

Clean Button

Up Arrow Button

Left Arrow Button

Figure 3-2 IntelliTec Control