11

G.

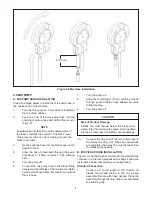

Install the remaining plastic fl ights, push the auger

into the freezing cylinder and rotate slowly until

the auger engages the drive shaft.

H.

Apply a thin layer of sanitary lubricant to the inside

and outside of the auger support bushing. Install

the bushing onto the auger support and install the

auger support into the front of the auger. Rotate

the auger support so that one leg of the support

points straight up.

I.

Assemble the air bleed valve o-ring onto the air

bleed valve. Position the o-ring into the groove

close to the wide part. Apply a thin fi lm of sanitary

lubricant to the o-ring.

J.

Insert the air bleed valve into the back of the front

door. Install the compression spring onto the air

bleed valve then screw the knob on fi nger tight.

K.

Apply a thin layer of sanitary lubricant to the

o-rings on the spigot body and install the spigot

body through the bottom of the front door.

L.

Apply a thin fi lm of sanitary lubricant to the door

seal o-ring and fi t it into the groove on the rear

of the front door.

M.

Place the front door assembly on the mounting

studs and the push front door against the machine

carefully.

N.

Secure the front door to the machine by placing

the knobs on the studs and tightening until fi nger

tight. Do not overtighten. Proper o-ring seal can

be observed through the transparent front door.

3.8 SANITIZING

Sanitizing must be done after the machine is clean and

just before the machine is fi lled with mix. Sanitizing the

night before is not effective. However, you should always

clean the machine and parts after using it.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that all

cleaning and sanitizing solutions used with food

processing equipment be certifi ed for this use.

When sanitizing the machine, refer to local sanitary regu-

lations for applicable codes and recommended sanitizing

products and procedures. The frequency of sanitizing

must comply with local health regulations. Mix sanitizer

according to manufacturer’s instructions to provide a 100

parts per million strength solution. Mix sanitizer in quanti-

ties of no less than 2 gallons of 90°F to 110°F (32°C to

43°C) water. Allow sanitizer to contact the surfaces to be

sanitized for 5 minutes. Any sanitizer must be used only

in accordance with the manufacturer’s instructions.

CAUTION

Risk of Product Damage

Avoid prolonged contact of sanitizer with machine

parts. Sanitizer may cause corrosion of stainless

steel parts if there is prolonged contact.

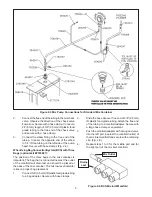

A.

Prepare 2 gallons of sanitizing solution following

the manufacturer’s instructions. Pour it into a

clean container and place the container into the

cabinet.

B.

Place the mix pump switch in the ON position

and open the air bleed valve on the front door

by pushing the valve in and holding (see Figure

3-8).

C. Let

sanitizing

solution

fi ll the freezing cylinder to

the air bleed valve. Close the valve by pulling it

out to lock it into place.

D.

Place the Main Power OFF/ON and Freezing

Cylinder OFF/ON switches in the ON position.

Press the CLEAN button.

E.

Check for leaks when the freezing cylinder is fi rst

pressurized with sanitizing solution.

1. Check for leaks at the front door seals.

2. Check the drain tray located in the side panel

for leaks coming from the rear of the rear auger

seal.

3. Check the inside of the cab unit for leaks at

the hose connections.

Figure 3-7 Front Door

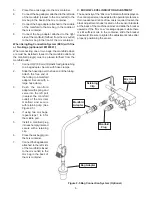

Figure 3-8 Air Bleed Valve

Air Bleed

Valve