20

Off Time (sec)

Increasing this value will increase the time between

freezing cycles in “Standby Mode” and result in

an increase of product temperature in the barrel.

Stb Time (sec)

This setting determines the total amount of time

in “Standby Mode”.

Sl1DrvOn (sec)

Adjustments to this setting affect the amount of

time the auger rotates in the stir cycle. This stir

cycle only occurs in “Sleep 1 Mode”.

Sl1DrOff (sec)

Adjustments to this setting affect the time between

stir cycles. The stir cycle only occurs in “Sleep 1

Mode”.

Sl2CutIn (°F)

Changing this setting affects the temperature at

which the freezing cycle starts in “Sleep 2 Mode”.

Sl2CtOut (°F)

Changing this setting affects the temperature at

which the freezing cycle stops in “Sleep 2 Mode”.

DftOffTm (sec)

In “Serve Mode”, this value determines the

maximum time without a freezing cycle. If this

value is met, a freezing cycle will start. In the event

of a freezing cylinder temperature sensor failure,

this value affects the amount of time between

freezing cycles during “Serve Mode”.

Refriger

This setting changes how the control handles

the storage refrigeration cycle. The setting for

the O411 is Cabinet.

CabCutIn (°F)

If the Refriger value is set to Cabinet, this

setting determines the temperature at which

the refrigeration cycle starts. If None, 1 Hopper,

or 2 Hopper is selected for the Refriger setting,

CabCutIn will not be shown on the IntelliTec menu.

CabCtOut (°F)

If the Refriger value is set to Cabinet, this

setting determines the temperature at which

the refrigeration cycle stops. If None, 1 Hopper,

or 2 Hopper is selected for the Refriger setting,

CabCtOut will not be shown on the IntelliTec

menu.

Cab Off

If the Refriger value is set to Cabinet and the

temperature sensor in the cabinet fails, this setting

determines the time between refrigeration cycles.

If None, 1 Hopper, or 2 Hopper is selected for the

Refriger setting, Cab Off will not be shown on the

IntelliTec menu.

Cab On

If the Refriger value is set to Cabinet and the

temperature sensor in the cabinet fails, this setting

determines the length of the refrigeration cycle. If

None, 1 Hopper, or 2 Hopper is selected for the

Refriger setting, Cab On will not be shown on the

IntelliTec menu.

4.8 OVERRUN

ADJUSTMENT

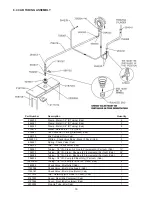

The product, when served, is a combination of air and

mix. Overrun is a measure of the amount of air blended

into the mix.

Overrun can be expressed in terms of the amount of

weight loss for a given volume. For example, if a pint of

liquid mix weighs 18 ounces and a pint of frozen product

with air added weighs 12 ounces, the overrun is said to

be 50 percent: 18 oz. - 12 oz. = 6 oz., (6/12) x 100 = 50%

The overrun can be checked by placing a one pint con-

tainer on an ice cream scale and zeroing out the scale.

Then fi ll a one pint container with frozen product. The

container should be fi lled over the top and leveled with

a straightedge. The product should not contain any air

pockets. When weighed on an ice cream scale, one pint

of product should weigh 12 to 13 ounces.

The mix pump has been preset at the factory to produce

a product with approximately 40% overrun. Because of

differences in mix formulation, temperatures and baro-

metric pressure, this fi gure may vary. It will be necessary

for approximately 2 gallons of mix to be pumped through

the machine before overrun changes in the product are

noticeable.

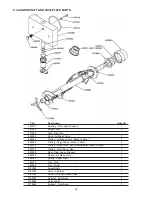

Overrun is controlled by the length of the air compressor

piston stroke within the piston cylinder. Lengthening the

stroke within the cylinder will increase overrun. Conversely,

shortening the stroke will decrease overrun. To perform

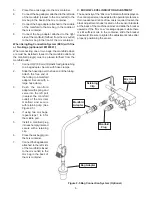

an overrun adjustment, refer to the following procedure:

WARNING

Hazardous Voltage

The Main Freezer Power switch must be placed in

the OFF position when disassembling for servicing.

The machine must be disconnected from electrical

supply before removing any access panel. Failure

to disconnect power before servicing could result

in death or serious injury.