28

5.4 TROUBLESHOOTING - MIX PUMP

PROBLEM

POSSIBLE CAUSE

REMEDY

Pump motor does

not run.

1. Power to pump is off.

1. Supply power to pump.

2. Low voltage.

2. Check for low voltage.

3. Mix pump hose jammed inside black

cover/clamp.

3. Disconnect pump from power source. Remove

four cover/clamp thumb screws. Separate

cover/clamp halves and remove outer half.

Remove jammed hose. Clean and re-install

cover/clamp and tighten four thumb screws

securely. Allow motor thermal overload to

reset.

4. Pump motor overloaded.

4. Allow internal thermal overload to reset;

determine overload cause and repair.

5. Pressure switch on pump is defective. 5. Check mechanical operation and continuity of

pressure switch.

6. Defective motor/capacitor.

6. Check motor amperage draw and/or capacitor.

Replace motor or capacitor.

7. Defective toggle switch.

7. Check continuity; repair or replace.

Pump operates but

cylinder will not fi ll.

NOTE 1: A PROPERLY WORKING PUMP WILL FILL AN 8 OZ. CUP WITH MIX IN ABOUT 9

SECONDS.

NOTE 2: IMMEDIATELY AFTER A BAG CHANGE THE PUMP MAY BE UNABLE TO

REESTABLISH IT’S PRIME WITH THE SYSTEM AT OPERATING PRESSURE. IN THIS

CASE, TURN THE PUMP OFF. DRAW 2-3 PINTS TO REDUCE SYSTEM PRESSURE TO

ZERO. TURN PUMP ON. PURGE REMAINING AIR IN MIX BAG AND PICK-UP HOSE.

IMPORTANT: Before connecting the pick-up hose to the mix bag, remove as much air

from the mix bag as possible.

1. Out of Mix.

1. Replenish mix supply.

2. Mix pump hose kinked inside black

cover/clamp.

2. Disconnect pump from power source. Remove

four cover/clamp thumb screws. Separate

cover/clamp halves and remove outer half.

Remove jammed hose. Clean and re-install

cover/clamp and tighten four thumb screws

securely. Allow motor thermal overload to

reset.

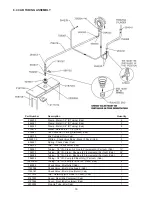

3. Hoses assembled incorrectly.

3. Refer to diagram for correct hose connections.

4. Mix pump hose service life is

exceeded.

4. Reposition/replace mix pump hose. See

Section 4.9

5. Mix pump hose not connected to

machine.

5. Connect mix pump hose to machine.

6. Ice crystals in mix.

6. Completely thaw mix prior to use.

7. Mix bag drawn against adapter.

7. Assure bag is clear of pick-up tube.

8. Foreign objects in mix.

8. Clear blockage. Use fresh mix.

9. Check valve is backwards.

9. Observe fl ow arrow for proper orientation.

Overrun too low or

no overrun.

1. Overrun setting too low.

1. Increase overrun setting.

2. Air leak.

2. Tighten all hose clamps.

3. Air compressor not pumping air.

3. Contact local Stoelting Distributor.

4. Air check valve in backwards.

4. Check arrow for direction of fl ow.