3

2.1 SAFETY PRECAUTIONS

Do not attempt to operate the freezer until the safety

precautions and operating instructions in this manual are

read completely and are thoroughly understood.

Take notice of all warning labels on the freezer. The

labels have been put there to help maintain a safe

working environment. The labels have been designed to

withstand washing and cleaning. All labels must remain

legible for the life of the freezer. Labels should be

checked periodically to be sure they can be recognized

as warning labels.

If danger, warning or caution labels are needed, indicate

the part number, type of label, location of label, and

quantity required along with your address and mail to:

STOELTING, LLC

ATTENTION: Customer Service

502 Hwy. 67

Kiel, Wisconsin 53042

Figure 3. Leveling Unit

2.3 FREEZER INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all crating, setting in

place, assembling parts, and cleaning.

A. Uncrate the freezer.

B. The freezer must be placed in a solid level position. To

level adjust casters.

C. The freezer is equipped with an air cooled condenser

and requires correct ventilation; the front is the intake

and the back is the discharge. Both front and back

require 3" clearance for proper operation.

D. Place all switches in the OFF position.

2.2 SHIPMENT AND TRANSIT

The freezer has been assembled, operated and in-

spected at the factory. Upon arrival at the final destina-

tion, the complete freezer must be checked for any

damage which may have occurred during transit.

With the method of packaging used, the freezer should

arrive in excellent condition. THE CARRIER IS RE-

SPONSIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCEALED.

Do not

pay the

freight bill until the freezer has been checked for dam-

age. Have the carrier note any visible damage on the

freight bill. If concealed damage and/or shortage is found

later, advise the carrier within 10 days and request

inspection. The customer must place claim for damages

and/or shortages in shipment with the carrier.

Stoelting,

Inc. cannot make any claims against the carrier.

SECTION 2

INSTALLATION INSTRUCTIONS

Summary of Contents for Optima SO218

Page 1: ...Optima SO218 318 OWNER S MANUAL Manual No 513571 Aug 2001 Rev 2 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 18: ...10 ...

Page 20: ...12 ...

Page 22: ...14 ...

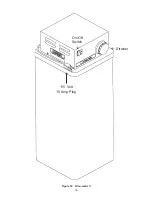

Page 24: ...16 Strainer On Off Switch 115 Volt 15 Amp Plug Ç Å È Figure 10 Fill o matic II ...

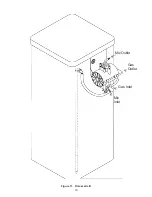

Page 26: ...18 Mix Outlet Gas Outlet Gas Inlet Mix Inlet É Ë Ë Ë Figure 11 Fill o matic III ...

Page 27: ...19 Gas Powered To Freezer Electric From Auto Fill Note Tubing Sold Separately 7 6 ...

Page 28: ......