11

4.1 ROUTINE CLEANING

To remove spilled or dried mix from the freezer exterior,

simply wash in the direction of the finish with warm

soapy water and wipe dry. Do not use highly abrasive

materials as they will mar the finish.

4.2PREVENTATIVE MAINTENANCE

It is recommended that a maintenance schedule be

followed to keep the freezer clean and operating prop-

erly.

WARNING

NEVER ATTEMPT TO REPAIR OR PERFORM

MAINTENANCE ON FREEZER UNTIL THE MAIN

ELECTRICAL POWER HAS BEEN DISCON-

NECTED.

A. Daily

1. The exterior should be kept clean at all times to

preserve the lustre of the stainless steel. A mild

alkaline cleaner is recommended. Use a soft cloth or

sponge to apply the cleaner.

B. Weekly

1. Check “O” Rings and rear seal for excessive wear

and replace if necessary.

2. Remove the drip tray and insert. Clean the drip

tray and insert and front of the freezer with a soap

solution.

C. Monthly

CAUTION

THE FREEZER HAS AN AIR COOLED CON-

DENSER AND MUST HAVE PROPER AIR CIRCU-

LATION. FAILURE TO CLEAN THE CONDENSER

ON A REGULAR BASIS MAY RESULT IN SERI-

OUS FREEZER DAMAGE AND COULD VOID

FREEZER WARRANTY.

1. Visually inspect the condenser for dirt by shining a

light through the coil from the fan side of the con

denser.

2. If the condenser is dirty, using compressed air or

CO2 tank, blow out the dirt from the fan side of the

condenser.

3. An alternative method of cleaning the condenser is to

use a condenser brush and vacuum.

NOTE

If the condenser is not kept clean, loss of refrigera-

tion efficiency will result, causing extended run time

or soft product consistency.

4.3 EXTENDED STORAGE

Refer to the following steps for storage of the freezer

over any long period of shutdown time:

A. Turn CLEAN/OFF/SERVE switch to the OFF posi-

tion.

B. Disconnect (unplug) from the electrical supply

source.

C. Clean thoroughly with a warm detergent all parts that

come in contact with the mix. Rinse in clear water

and dry all parts. Do not sanitize.

NOTE

Do not let the cleaning or sanitizing solution stand

in the hopper or in the freezer barrel during the shut-

down period.

D. Remove, disassemble, and clean the front door, and

agitator parts. Place the agitator blades and the front

agitator support bearing in a plastic bag with a moist

paper towel to prevent them from becoming brittle.

4.4 CONSISTENCY ADJUSTMENT

The consistency adjustment knob is located behind the

right side panel near the back. Remove black plug to

access. To adjust use a straight bladed screwdriver.

Turn clockwise for a thicker product and counterclock-

wise for a thinner product. Allow 15-30 minutes for the

product to change consistency.

SECTION 4

PREVENTIVE MAINTENANCE

Summary of Contents for Optima SO218

Page 1: ...Optima SO218 318 OWNER S MANUAL Manual No 513571 Aug 2001 Rev 2 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 18: ...10 ...

Page 20: ...12 ...

Page 22: ...14 ...

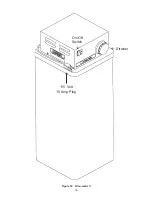

Page 24: ...16 Strainer On Off Switch 115 Volt 15 Amp Plug Ç Å È Figure 10 Fill o matic II ...

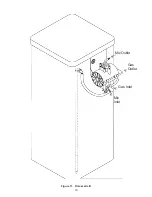

Page 26: ...18 Mix Outlet Gas Outlet Gas Inlet Mix Inlet É Ë Ë Ë Figure 11 Fill o matic III ...

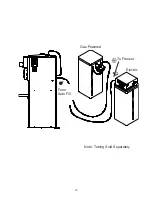

Page 27: ...19 Gas Powered To Freezer Electric From Auto Fill Note Tubing Sold Separately 7 6 ...

Page 28: ......