37

Part

Number

Description

Quantity

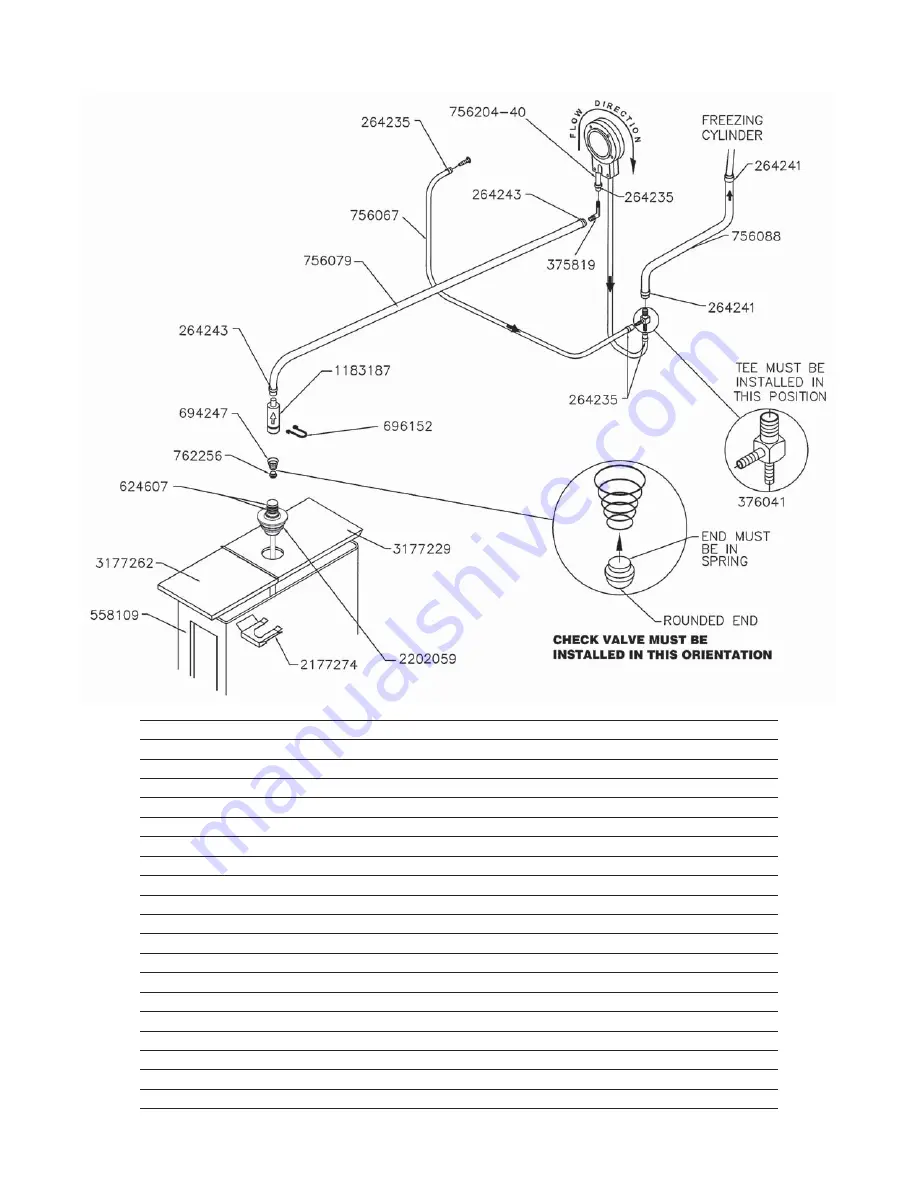

264235

Clamp - Metal (1/4” ID Tubing) (Cab)

8

264241

Clamp - Metal (1/2” ID Tubing) (Cab)

4

264243

Clamp - Metal (3/8” ID Tubing) (Cab)

8

375819

Elbow - Barbed (3/8”- 1/4”) (Cab)

2

376041

Tee Connector - 3-Way (Stainless) (Cab)

2

558109

Mix Container Only (Cab)

2

624607

O-Ring - Check Valve Body - Black (Cab)

4

694247

Spring - Cone (Spigot Cam) (Soft Serve) & (Cab Check Valve)

2

696152

Clip - Lock (Check Valve) (Cab)

6

756067

Tubing - 1/4” ID - Clear - Air Line (25’ Increments) (Per Inch)

Two 13”

756079

Tubing - 3/8” ID - Clear - Mix Line (25’ Increments) (Per Inch)

Two 24”

756088

Tubing - 1/2” ID - Clear - Mix Line (25’ Increments) (Per Inch)

Two 6”

756204

Tubing - 1/4” ID - Pump (50’ Box Only) (Per Inch) (Cab)

-

756204-40

Tubing - 1/4” ID - Pump (Pre-Cut 40” Piece) (Cab)

8

762256

Check Valve - Mix Outlet (Cab)

2

1183187

Check Valve - Mix In Line (Outer) (Cab)

2

2177274

Clip - Retaining (Mix Probe To Cover) (Cab)

2

2187307

Pick-Up Tube - Mix (Cab)

2

3177229

Cover - Rear (Mix Container) (Cab)

2

3177262

Cover - Front (Mix Container) (Cab)

2

6.5 CAB

TUBING