English

Operating instructions

19

9

M

AINTENANCE

The machine requires a very limited maintenance. Periodically, we suggest to:

-

check the good conditions of the machine's parts;

-

check that the electric power cable is not damaged;

-

Try the efficiency of the safety devices (ref. Par. 8.2).

It is then useful to maintain the external panels clean and the surrounding area. Dust, paper fragments or other small objects

may penetrate in the machine through the ventilation loopholes (in particular if equipped with air condensation and rapidly

compromise its correct functioning.

The inside parts, to which the user MUST NOT accede, must be checked by the Assistance Service (ref. Par. 8. 3)

9.1

Maintenance during the disassembling of the parts

Check the integrity of gaskets (indicated with [G] in the figure) and substitute those that

are deteriorated.

Use exclusively original, compatible with food, rubber gaskets.

The spare bag

contains a complete series of gaskets approved by the manufacturer.

To correctly replace the gaskets it is necessary to:

-

remove the old gaskets by using a sharp tool, possibly non- metallic, paying attention not to scratch the seating of the

gaskets themselves;

-

clean the seatings and the gaskets from any kind of grease before inserting the new gaskets.

A yearly preventive replacement of all wearing parts and all gaskets is recommended. We suggest you to always keep a

spare supply: to order it, make reference to the Spares Section contained in the Technical Handbook.

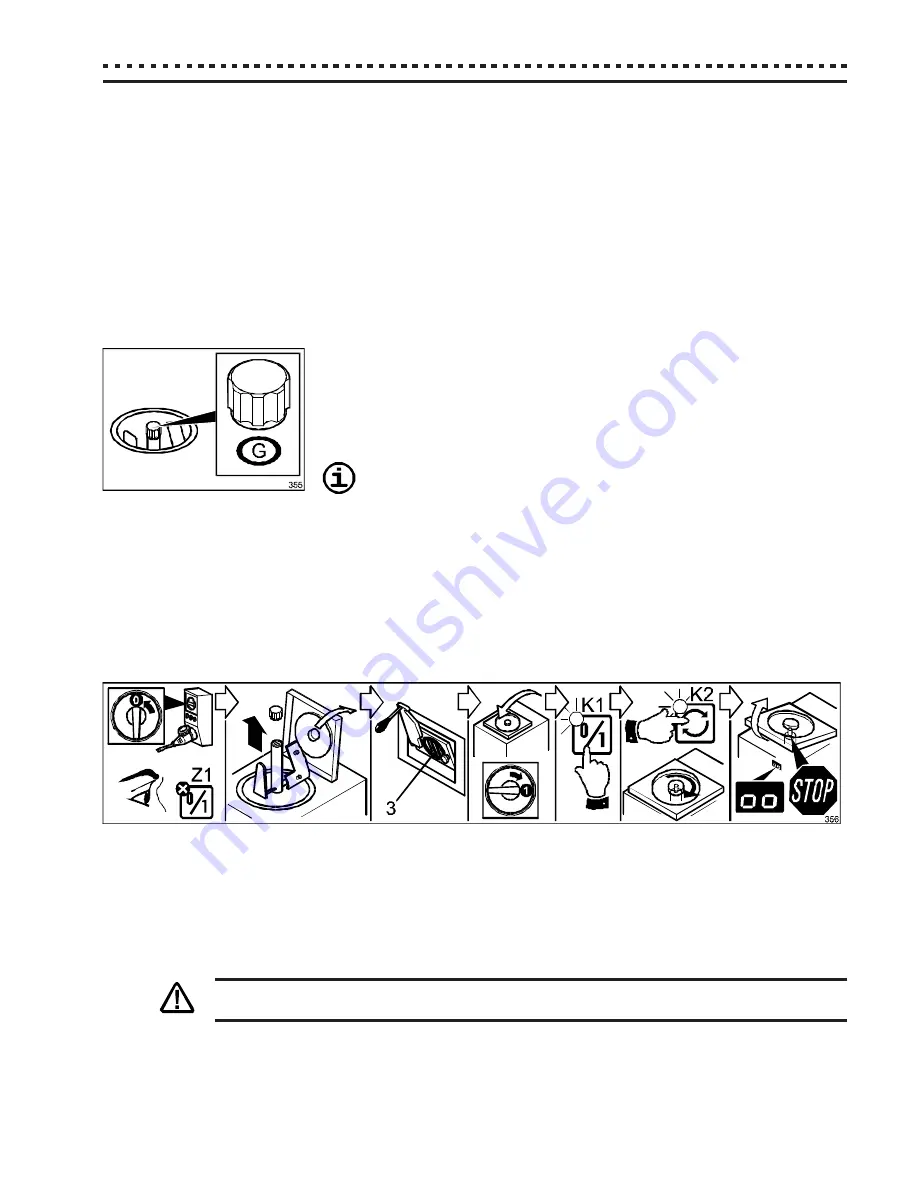

9.2

Checking of safety devices

Every three months, check that all safety devices on your machine are in perfect working order:

-

open the lid and remove the beater;

-

check that the protection grill [3] is well fixed and not damaged;

-

close lid and supply the machine;

-

turn beating on (beater's shaft will start). Then open the lid. Provided that the lid’s magnetic contact is correctly

working, the beater’s shaft will stop immediately and the Display will show “oo” (two small squares).

If the machine’s functioning is as described, the safety devices are efficient.

T

HE MACHINE MUST

NOT

BE USED IF ONE OR MORE OF THE SAFETY DEVICES SHOULD

RESULT DAMAGED OR MALFUNCTIONING

!