9

GB

Operating principle

This is a fully modulating boiler.

The control unit of the boiler adapts

the modulation ratio automatically to

the heat demand requested by the

system. This is done by controlling

the speed of the fan.

As a result, the Whirlwind mixing

system will adapt the gas ratio to the

chosen fan speed, in order to maintain

WKHEHVWSRVVLEOHFRPEXVWLRQ¿JXUHV

DQG WKHUHZLWK WKH EHVW HI¿FLHQF\

7KH ÀXH JDVHV FUHDWHG E\ WKH

combustion

are

transported

downwards through the heat exchan-

ger and leave the boiler at the

top into the chimney connection.

The return water from the system

enters the boiler in the lower section,

ZKHUHLVWKHORZHVWÀXHJDVWHPSH

-

UDWXUH LQ WKH ERLOHU ,Q WKLV VHFWLRQ

condensation

takes

place.

The

water

is

being

transpor-

ted upwards through the heat

exchanger, in order to leave the

ERLOHU DW WKH ÀRZ FRQQHFWLRQ

7KHFURVVÀRZZRUNLQJSULQFLSOHZD

-

WHU XS ÀXH JDV GRZQ HQVXUHV WKH

PRVW HI¿FLHQW FRPEXVWLRQ UHVXOWV

The LMS14 control unit can control

WKHERLOHURSHUDWLRQEDVHGRQ

boiler control (standalone opera-

tion);

weather compensated operation

(with optional outdoor sensor);

ZLWK 9 H[WHUQDO LQÀXHQFH

(temperature or capacity) from a

building management system.

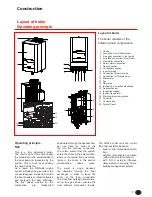

Layout of boiler

The boiler consists of the

following

PDLQFRPSRQHQWV

1

2

3

4

5

6

7

9

10

11

12

13

14

15

16

17

19

20

21

22

Casing

Access door for Control panel

Flue gas connection (+ test point)

Air intake connection (+ test point)

Flow water connection

Return water connection

Gas connection

Condensate syphon

,QSXWIRUZLULQJ

Connection for safety valve

&RQQHFWLRQIRU¿OOGUDLQYDOYH

Manometer

Fan

Gas valve

,JQLWLRQDQGLRQLVDWLRQHOHFWURGHV

Heat exchanger

,QVSHFWLRQZLQGRZ

,JQLWLRQWUDQVIRUPHU

Electrical input connections

Controller

Condens tray

Control Panel

Construction

Layout of boiler

Operating principle

1

2

4

3

12

10

5

8

7 9

6

11

16

22

20

19

21

13

14

18

15

17

R40