20IP18B

8

2.3

Principle of regulation

Electronic Modulating version

This type of boiler control regulation (indicated by the EM

control option) uses a built-in PID regulator to maintain a con-

stant flow temperature to within a minimum temperature devia-

tion of +1 to -1 K.

This system allows the user to fine-tune the reaction of the

boiler to the heating system or application process.

An added bonus with this “EM” control system is that it allows a

Building Management system to influence the flow temperature

using a 0 - 10 VDC control signal.

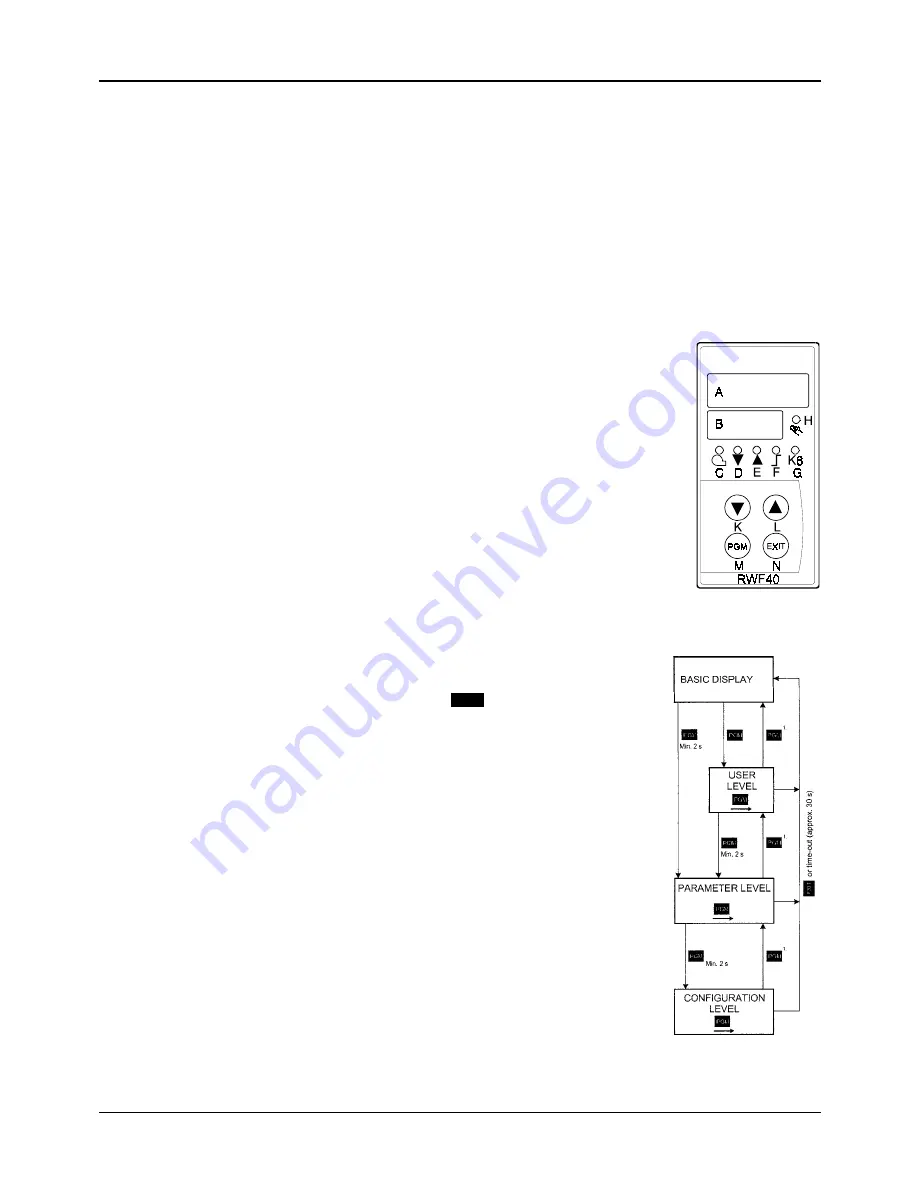

Boiler temperature controller RWF40

A Process value (actual temperature)

B Set point (temperature)

C Burner enable (not applicable)

D Mod. indicator (decrease fire rate)

E Mod. indicator (increase fire rate)

F Two-stage firing (not applicable)

G Limit comparator

H Manual operation

The keys K-L-M-N are used for displaying

values and changing parameters in the

temperature controllers configuration.

K Down key (reduce value)

L Up key (increase value)

M Programme key

N Exit key

Assignment of levels

All levels can be accessed from the basic

display via the

button, as shown in

PGM

the diagram. The upper actual value dis-

play (red) indicates the actual value and

the parameter values for the various levels.

The setpoint and the parameters are

indicated in the lower setpoint display

(green).

1. After using

*

PGM

+

to step through all

the parameters of a level, an automatic

return occurs after the last parameter has

been confirmed.

Summary of Contents for ECONOPAK R2000

Page 6: ...20IP18B VI ...

Page 65: ...20IP18B 57 ...