9

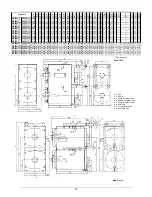

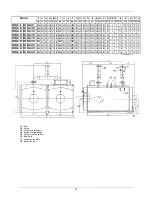

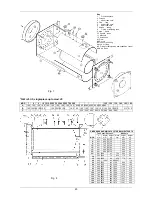

2.4 REX DUAL/REX DUAL F (stacked) 14-170 BOILER

Characteristics

Efficiency 100%

(N.C.V.)

Effic. 100%

(stars)

NG max flow

rate G20

NG max flow

rate G30

NG max flow

rate G31

Max flow rate

of flues

Efficiency at 30%

(N.C.V.)

kW

kcal/h

kW

kcal/h

%

%

m³/h

kg/h

kg/h

kg/h

%

Medium Temp.

70°C

(Efficienty Dir.

92/42/CEE)

Medium Temp.

70°C

REX DUAL 14

140

120.000

152

130.720

92,11

**

16,08

11,94

11,81

239,59

91,40

REX DUAL 16

160

138.000

174

149.640

91,95

**

18,41

13,67

13,52

274,31

91,50

REX DUAL 18

180

155.000

196

168.560

91,84

**

20,74

15,39

15,23

309,03

91,55

REX DUAL 20

200

172.000

218

187.480

91,74

**

23,07

17,12

16,94

343,74

91,66

REX DUAL 24

240

206.000

260

223.600

92,31

**

27,51

20,42

20,20

409,90

91,45

REX DUAL 30

300

258.000

326

280.360

92,02

**

34,50

25,60

25,33

514,05

91,30

REX DUAL 40

400

344.000

432

371.520

92,59

**

45,71

33,93

33,56

681,08

91,36

REX DUAL 50

500

430.000

542

466.120

92,25

-

57,35

42,57

42,11

854,52

91,70

REX DUAL 60

600

516.000

650

559.000

92,31

-

68,78

51,05

50,50

1024,82

91,90

REX DUAL 70

700

602.000

758

651.880

92,35

-

80,21

59,53

58,89

1195,13

91,90

REX DUAL 80

800

688.000

866

744.760

92,38

-

91,64

68,01

67,28

1365,44

91,80

REX DUAL 100

1000

860.000

1084

932.240

92,25

-

114,71

85,14

84,21

1709,18

91,90

REX DUAL 124

1240

1.066.000 1344 1.155.840

92,26

-

142,22

105,56

104,41

2119,08

91,80

REX DUAL 150

1500

1.290.000 1626 1.398.360

92,25

-

172,06

127,70

126,32

2563,69

91,80

REX DUAL 170

1700

1.462.000 1842 1.584.120

92,29

-

194,92

144,67

143,10

2904,31

91,80

Heat output

Heat input

Medium Temp.

70°C

Characteristics

Pressure losses

flue gas side

Heat losses through

the chimney

Heat losses through

the casing

Heat losses with

burner off

Press. losses

water side

Design

Pressure

Total

capacity

Total

weight

Electric

supply

Frequency

Insulation

class

Electric

power

mbar

%

%

%

°C

°C

°C

%

%

%

mbar

bar

l

kg

Volt ~

Hz

IP

W

GAS GASOIL HEAVY OIL GAS GASOIL HEAVY OIL

(

Δ

T=12K)

With electr.

contr. (excluded

pump and burner)

N

at. g

as

Lp

g

Ga

so

il

He

av

y o

il

REX DUAL 14

0,8

7,09

0,80

0,10

188 191

191

10,5 13,5

14,0

11

5

210

465

230

50

IP40

20

X X X X

REX DUAL 16

1,0

7,25

0,80

0,10

192 195

194

10,5 13,5

14,0

14

5

210

465

230

50

IP40

20

X X X X

REX DUAL 18

0,8

7,36

0,80

0,10

194 197

197

10,5 13,5

14,0

18

5

246

549

230

50

IP40

20

X X X X

REX DUAL 20

1,0

7,46

0,80

0,10

197 199

199

10,5 13,5

14,0

22

5

246

549

230

50

IP40

20

X X X X

REX DUAL 24

1,1

6,89

0,80

0,10

184 186

186

10,5 13,5

14,0

32

5

246

549

230

50

IP40

20

X X X X

REX DUAL 30

1,2

7,18

0,80

0,10

190 193

193

10,5 13,5

14,0

22

5

344

726

230

50

IP40

20

X X X X

REX DUAL 40

1,9

6,61

0,80

0,10

177 180

180

10,5 13,5

14,0

38

5

344

726

230

50

IP40

20

X X X X

REX DUAL 50

2,0

6,95

0,80

0,10

185 188

187

10,5 13,5

14,0

60

5

440

898

230

50

IP40

20

X X X X

REX DUAL 60

2,0

6,89

0,80

0,10

184 186

186

10,5 13,5

14,0

86

5

600

986

230

50

IP40

20

X X X X

REX DUAL 70

2,9

6,85

0,80

0,10

183 186

185

10,5 13,5

14,0

118

5

712

1122

230

50

IP40

20

X X X X

REX DUAL 80

4,1

6,82

0,80

0,10

182 185

184

10,5 13,5

14,0

63

5

720

1285

230

50

IP40

20

X X X X

REX DUAL 100

4,2

6,95

0,80

0,10

185 188

187

10,5 13,5

14,0

98

5

1080 1830

230

50

IP40

20

X X X X

REX DUAL 124

6,4

6,94

0,80

0,10

185 188

187

10,5 13,5

14,0

62

5

1290 2065

230

50

IP40

20

X X X X

REX DUAL 150

5,2

6,95

0,80

0,10

185 188

187

10,5 13,5

14,0

44

5

1710 2621

230

50

IP40

20

X X X X

REX DUAL 170

7,2

6,91

0,80

0,10

184 187

187

10,5 13,5

14,0

56

5

1710 2621

230

50

IP40

20

X X X X

Flue gas temp. at boiler

output and air at 20 deg. C

CO2

Fuel

Characteristics

Efficiency 100%

(N.C.V.)

Effic. 100%

(stars)

NG max flow

rate G20

NG max flow

rate G30

NG max flow

rate G31

Max flow rate

of flues

Efficiency at 30%

(N.C.V.)

kW

kcal/h

kW

kcal/h

%

%

m³/h

kg/h

kg/h

kg/h

%

Medium Temp.

70°C

(Efficienty Dir.

92/42/CEE)

Medium Temp.

70°C

REX DUAL 14 F

140

120.000

148

127.624

94,34

***

15,70

11,66

11,53

233,93

94,80

REX DUAL 16 F

160

138.000

169

145.684

94,45

***

17,93

13,30

13,16

267,16

94,70

REX DUAL 18 F

180

155.000

190

163.744

94,54

***

20,15

14,95

14,79

300,24

95,00

REX DUAL 20 F

200

172.000

211

181.632

94,70

***

22,35

16,59

16,41

333,02

94,80

REX DUAL 24 F

240

206.000

253

217.580

94,86

***

26,77

19,87

19,65

398,87

95,10

REX DUAL 30 F

300

258.000

316

271.416

95,06

***

33,40

24,79

24,52

497,66

95,70

REX DUAL 40 F

400

344.000

420

361.200

95,24

***

44,44

32,99

32,63

662,16

95,30

REX DUAL 50 F

500

430.000

527

453.220

94,88

-

55,77

41,39

40,94

830,97

95,38

REX DUAL 60 F

600

516.000

631

542.660

95,09

-

66,77

49,56

49,02

994,87

95,59

REX DUAL 70 F

700

602.000

734

631.240

95,37

-

77,67

57,65

57,02

1157,28

95,60

REX DUAL 80 F

800

688.000

840

722.400

95,24

-

88,89

65,97

65,26

1324,46

95,40

REX DUAL 100 F

1000

860.000

1048

901.280

95,42

-

110,90

82,31

81,42

1652,41

95,70

REX DUAL 124 F

1240

1.066.000 1298 1.116.280

95,53

-

137,35

101,94

100,84

2046,52

95,90

REX DUAL 150 F

1500

1.290.000 1572 1.351.920

95,42

-

166,35

123,46

122,12

2478,62

95,92

REX DUAL 170 F

1700

1.462.000 1782 1.532.520

95,40

-

188,57

139,96

138,44

2809,69

95,80

Heat output

Heat input

Medium Temp.

70°C

Characteristics

Pressure losses

flue gas side

Heat losses through

the chimney

Heat losses through

the casing

Heat losses with

burner off

Flue gas temp. at boiler

output and air at 20 deg. C

CO2

Press. losses

water side

Design

Pressure

Total

capacity

Total

weight

Electric

supply

Freque

ncy

Insulation

class

Electric

power

mbar

%

%

%

°C

%

mbar

bar

l

kg

Volt ~

Hz

IP

W

GAS

GAS

(

Δ

T=12K)

With electr.

contr. (excluded

pump and burner)

N

at. g

as

Lp

g

Ga

so

il

H

eav

y oi

l

REX DUAL 14 F

0,9

5,16

0,50

0,10

148

11,0

11

5

210

477

230

50

IP40

20

X X -

-

REX DUAL 16 F

1,1

5,05

0,50

0,10

146

11,0

14

5

210

477

230

50

IP40

20

X X -

-

REX DUAL 18 F

0,9

4,96

0,50

0,10

143

11,0

18

5

246

565

230

50

IP40

20

X X -

-

REX DUAL 20 F

1,1

4,80

0,50

0,10

140

11,0

22

5

246

565

230

50

IP40

20

X X -

-

REX DUAL 24 F

1,3

4,64

0,50

0,10

136

11,0

32

5

246

565

230

50

IP40

20

X X -

-

REX DUAL 30 F

1,3

4,44

0,50

0,10

131

11,0

22

5

344

748

230

50

IP40

20

X X -

-

REX DUAL 40 F

2,2

4,26

0,50

0,10

127

11,0

38

5

344

748

230

50

IP40

20

X X -

-

REX DUAL 50 F

2,4

4,62

0,50

0,10

135

11,0

60

5

440

920

230

50

IP40

20

X X -

-

REX DUAL 60 F

2,4

4,41

0,50

0,10

130

11,0

86

5

600

1014

230

50

IP40

20

X X -

-

REX DUAL 70 F

3,4

4,13

0,50

0,10

124

11,0

118

5

712

1154

230

50

IP40

20

X X -

-

REX DUAL 80 F

4,7

4,26

0,50

0,10

127

11,0

63

5

720

1317

230

50

IP40

20

X X -

-

REX DUAL 100 F

4,8

4,08

0,50

0,10

122

11,0

98

5

1080

1866

230

50

IP40

20

X X -

-

REX DUAL 124 F

7,3

3,97

0,50

0,10

120

11,0

62

5

1290

2101

230

50

IP40

20

X X -

-

REX DUAL 150 F

5,8

4,08

0,50

0,10

122

11,0

44

5

1710

2671

230

50

IP40

20

X X -

-

REX DUAL 170 F

8,0

4,10

0,50

0,10

123

11,0

56

5

1710

2671

230

50

IP40

20

X X -

-

Fuel

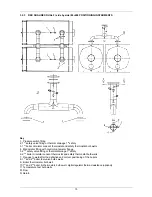

Summary of Contents for REX F

Page 1: ...TECHNICAL MANUAL REX REX F REX K REX K F REX DUAL REX DUAL F PRESSURISED STEEL BOILERS...

Page 2: ......

Page 18: ...18 1 2 6 3 4 5 9...

Page 30: ......

Page 32: ...ASSEMBLY INSTRUCTIONS STAVES LINING...

Page 33: ......