Operation

12

Battery-operated suction sweeper KSE 1000

Make sure the dust collector has been installed

Move the lever of the filter vibrating device continuously, about ten

times back and forth.

Afterwards open the ventilation flap.

4.3

Parking the sweeper

Turning Off the Sweeping & Suction Machine

Make sure the suction sweeper is on level ground when you loosen

the parking brake, or secure the suction sweeper to prevent acci-

dental rolling!

Release the driving lever.

Lift the lateral brushes and arrest the lowering lever of the lateral

brushes.

Lift the sweeping rollers and arrest the lowering lever of the sweep-

ing rollers.

Turn the key counter clockwise and take it out off the key operated

switch.

Pull the machine towards in yourself, to ensure that the front wheel

is straight.

Secure the machine from rolling by kicking down the brake lever of

the front wheel.

If the brake is relieved afterwards, the brake lever has to remain

depressed position.

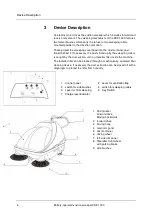

1 Parking brake

2

Front wheel

CAUTION!