- 20 -

MAINTENANCE

INTRODUCTION

Congratulations on your purchase of the LJS2000

Lift Jockey! Youve made an excellent choice. The

Lift Jockey is specifically designed for lifting and

transporting a wide variety of materials on your job

site. Your new Lift Jockey comes standard with the

following features:

Mast Height -

Choice of three (3) interchangeable,

rugged, high lift masts. Lift from heights of 76 to

96. Masts tilt forward and reverse for easy han-

dling and discharging of loads.

Load/Speed Capacity

- Lifts and moves up to 1,000

lbs. at speeds up to 3 mph for getting around any site

faster.

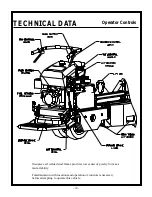

Controls

- Forward and reverse travel controlled by

handle grips on steering handle. All controls--horn,

throttle, tilt control and lift/lower are within opera-

tors reach. Power controls automatically return to

neutral position when released.

Hydrostatic Drive

- Clean, quiet with totally

enclosed hydraulic drive circuit. Provides reliability,

lower maintenance and longer life.

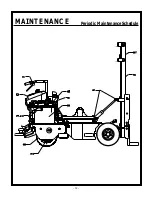

Engine Cowl

- Allows easy access to all mainte-

nance points for quick service. Provides optimum

airflow for cooler running and longer life on compo-

nents.

Lift Points

Provide two means to lift with forks or

a hoist. Two sets of fork loops are located width-

wise under the frame and a lift eye under the front

hood. Allows easy transport for unit and placing on

elevated platforms.

Tires

- Foam-filled drive and load tires provide the

added toughness and reliability on a job site.

Forks

- Four interchangeable, adjustable fork options

provide efficient handling of all types of loads.

Choose from round block forks or box forks for

several different pallet sizes. The 22 inch invertable

box forks can be used to increase effective lifting

height for applications such as setting lintels.

KNOW YOUR LIFT

Read and understand the owners manual before

starting the unit. Make sure you understand the

purpose of every control. Refer to ASME Standard

B56.1-2000 amended with B56.19-2001 Standard

for forklift safety training. When operating the unit,

remember the capacity it can carry and adjust speed

and load for changing conditions.

Pre-Operation Checklist

Upon receipt of your

Lift Jockey,

CAREFULLY CHECK FOR ANY

FREIGHT DAMAGE.

Any damage should be

immediately reported to the carrier and a claim

registered.

The Lift Jockey is manufactured to the strictest

specifications and inspection procedures. After

inspecting the quality of the workmanship of your

machine, please complete and return the tag on the

machine with the assemblers signature with your

findings to Stone. We value our customers input

and welcome any and all comments on how the

product may serve you better.

The following instructions were compiled to provide

you information on how to obtain long and trouble-

free use of the unit. Read and understand the

owners manual before starting the unit. Make sure

you understand the purpose of every control. When

operating the unit, know the capacity it can carry

and adjust the speed and load for changing condi-

tions.

Intro/Know Your Lift

Summary of Contents for Lift Jockey LJS2000

Page 2: ......

Page 13: ...13 TECHNICAL DATA Hardware...

Page 34: ...34 MAINTENANCE Periodic Maintenance Schedule...

Page 35: ...35 MAINTENANCE Periodic Maintenance Schedule...

Page 38: ......

Page 40: ...40 PARTS LIST Tilt Cylinder Front Cowl Assembly...

Page 41: ...41 PARTS LIST Tilt Cylinder Front Cowl Assembly...

Page 42: ...42 PARTS LIST Engine Cowl Assembly...

Page 43: ...43 PARTS LIST Engine Cowl Assembly...

Page 44: ...44 PARTS LIST Engine Assembly...

Page 45: ...45 PARTS LIST Engine Assembly...

Page 46: ...46 PARTS LIST Pump Assembly...

Page 47: ...47 PARTS LIST Pump Assembly...

Page 48: ...48 PARTS LIST Battery Hose Clamp Assembly...

Page 49: ...49 PARTS LIST Battery Hose Clamp Assembly...

Page 50: ...50 PARTS LIST Steering Housing Assembly...

Page 51: ...51 PARTS LIST Steering Housing Assembly...

Page 52: ...52 PARTS LIST Hydraulic Tank Assembly...

Page 53: ...53 PARTS LIST Hydraulic Tank Assembly...

Page 54: ...54 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Page 55: ...55 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Page 56: ...56 PARTS LIST Platform Brake Pedal Assembly...

Page 57: ...57 PARTS LIST Platform Brake Pedal Assembly...

Page 58: ...58 PARTS LIST Brake Linkage Assembly...

Page 59: ...59 PARTS LIST Brake Linkage Assembly...

Page 60: ...60 PARTS LIST Wheelmotor Brake Tire Assembly...

Page 61: ...61 PARTS LIST Wheelmotor Brake Tire Assembly...

Page 62: ...62 PARTS LIST Quick Change Hub Assembly...

Page 63: ...63 PARTS LIST Quick Change Hub Assembly...

Page 64: ...64 PARTS LIST Hand Foot Mast Control Assembly...

Page 65: ...65 PARTS LIST Hand Foot Mast Control Assembly...

Page 66: ...66 PARTS LIST Mast Assembly...

Page 67: ...67 PARTS LIST Mast Assembly...

Page 68: ...68 PARTS LIST Mast Assembly...

Page 69: ...69 PARTS LIST Mast Assembly...

Page 70: ...70 PARTS LIST Lift Frame Assembly...

Page 71: ...71 PARTS LIST Lift Frame Assembly...

Page 72: ...72 PARTS LIST Hydraulic Piping Schematic...

Page 73: ...73 PARTS LIST Hydraulic Piping Schematic...

Page 74: ...74 PARTS LIST Hydraulic Piping Schematic...

Page 75: ...75 PARTS LIST Hydraulic Piping Schematic...

Page 76: ...76 PARTS LIST Hydraulic System Schematic...

Page 77: ...77 PARTS LIST Hydraulic System Schematic...

Page 78: ...78 PARTS LIST Electrical Wiring Schematic...

Page 79: ...79 PARTS LIST Electrical Wiring Schematic...

Page 80: ...80 PARTS LIST 55398 Decal Identification...

Page 82: ...82 PARTS LIST Decal Identification...

Page 84: ......

Page 85: ......

Page 86: ......