- 22 -

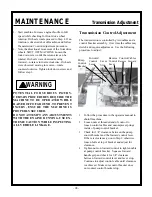

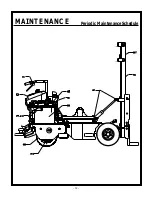

MAINTENANCE

DO NOT RUN UNIT IN AN EN-

CLOSED, NON-VENTILATED AREA

AVOID PROLONGED BREATHING

OF VAPORS AND SKIN CONTACT--

SERIOUS ILLNESS OR LOSS OF LIFE

COULD RESULT

Fuel Tank--

Gasoline ONLY (see Engine Specifica-

tions Section for requirements).

Fill fuel tank at the end of each days operation to

prevent condensation in the tank.

Drain and flush fuel tank every 1,000 hours or 12

months.

Avoid storing fuel over long periods of time. If fuel

is stored for more than a month prior to use or there

is a slow turnover in fuel tank or supply tank, add a

fuel conditioner to stabilize the fuel and prevent

water condensation. Fuel conditioner also reduces

fuel gelling and controls wax separation during cold

weather.

Proper fuel storage is critically important. Use clean

storage and transfer tanks. Periodically drain water

and sediment from the bottom of the tank. Store fuel

in a convenient place away from buildings.

HYDRAULIC OIL

The hydraulic drive motors are extremely reliable

and will ordinarily not need maintenance or repair.

If a vibration is experienced with engine running,

check the coupler between the engine and the

hydraulic pump.

Do not

make this inspection while

engine is running. It will be necessary to remove the

inspection cover. After adjusting and tightening the

WARNING

Fuel Tank/Hydraulic Oil

coupler, replace the inspection cover and then start

engine to see if the problem has been corrected.

Do

not

run the engine or operate the Lift with the cover

removed or not firmly attached.

ESCAPING HYDRAULIC FLUID UN-

DER PRESSURE CAN HAVE SUFFI-

CIENT FORCE TO PENETRATE THE

SKIN, CAUSING SERIOUS PER-

SONAL INJURY.

HYDRAULIC FLUID ESCAPING UN-

DER PRESSURE FROM A VERY

SMALL HOLE CAN BE ALMOST IN-

VISIBLE. USE A PIECE OF CARD-

BOARD OR WOOD TO SEARCH FOR

POSSIBLE LEAKS. NEVER USE

YOUR HANDS TO DETECT PRES-

SURE LEAKS. IF YOU ARE INJURED

BY ESCAPING HYDRAULIC FLUIDS,

SEE A DOCTOR AT ONCE. SERIOUS

INFECTION OR REACTION CAN DE-

VELOP IF PROPER MEDICAL

TREATMENT IS NOT ADMINIS-

TERED IMMEDIATELY.

Mobil 424 SUS255/55CST ISO VG55 is recom-

mended for the hydraulic system. Do not mix

hydraulic oils. Check oil level daily, replace

hydraulic oil every 800 hours.

Remove return filter cap slowly.

Remove drain plug and drain into suitable

container.

Clean drain plug, apply thread sealant to the

plug, install and tighten.

WARNING

Summary of Contents for Lift Jockey LJS2000

Page 2: ......

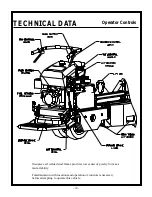

Page 13: ...13 TECHNICAL DATA Hardware...

Page 34: ...34 MAINTENANCE Periodic Maintenance Schedule...

Page 35: ...35 MAINTENANCE Periodic Maintenance Schedule...

Page 38: ......

Page 40: ...40 PARTS LIST Tilt Cylinder Front Cowl Assembly...

Page 41: ...41 PARTS LIST Tilt Cylinder Front Cowl Assembly...

Page 42: ...42 PARTS LIST Engine Cowl Assembly...

Page 43: ...43 PARTS LIST Engine Cowl Assembly...

Page 44: ...44 PARTS LIST Engine Assembly...

Page 45: ...45 PARTS LIST Engine Assembly...

Page 46: ...46 PARTS LIST Pump Assembly...

Page 47: ...47 PARTS LIST Pump Assembly...

Page 48: ...48 PARTS LIST Battery Hose Clamp Assembly...

Page 49: ...49 PARTS LIST Battery Hose Clamp Assembly...

Page 50: ...50 PARTS LIST Steering Housing Assembly...

Page 51: ...51 PARTS LIST Steering Housing Assembly...

Page 52: ...52 PARTS LIST Hydraulic Tank Assembly...

Page 53: ...53 PARTS LIST Hydraulic Tank Assembly...

Page 54: ...54 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Page 55: ...55 PARTS LIST Steering Handle Bar Fuel Tank Assembly...

Page 56: ...56 PARTS LIST Platform Brake Pedal Assembly...

Page 57: ...57 PARTS LIST Platform Brake Pedal Assembly...

Page 58: ...58 PARTS LIST Brake Linkage Assembly...

Page 59: ...59 PARTS LIST Brake Linkage Assembly...

Page 60: ...60 PARTS LIST Wheelmotor Brake Tire Assembly...

Page 61: ...61 PARTS LIST Wheelmotor Brake Tire Assembly...

Page 62: ...62 PARTS LIST Quick Change Hub Assembly...

Page 63: ...63 PARTS LIST Quick Change Hub Assembly...

Page 64: ...64 PARTS LIST Hand Foot Mast Control Assembly...

Page 65: ...65 PARTS LIST Hand Foot Mast Control Assembly...

Page 66: ...66 PARTS LIST Mast Assembly...

Page 67: ...67 PARTS LIST Mast Assembly...

Page 68: ...68 PARTS LIST Mast Assembly...

Page 69: ...69 PARTS LIST Mast Assembly...

Page 70: ...70 PARTS LIST Lift Frame Assembly...

Page 71: ...71 PARTS LIST Lift Frame Assembly...

Page 72: ...72 PARTS LIST Hydraulic Piping Schematic...

Page 73: ...73 PARTS LIST Hydraulic Piping Schematic...

Page 74: ...74 PARTS LIST Hydraulic Piping Schematic...

Page 75: ...75 PARTS LIST Hydraulic Piping Schematic...

Page 76: ...76 PARTS LIST Hydraulic System Schematic...

Page 77: ...77 PARTS LIST Hydraulic System Schematic...

Page 78: ...78 PARTS LIST Electrical Wiring Schematic...

Page 79: ...79 PARTS LIST Electrical Wiring Schematic...

Page 80: ...80 PARTS LIST 55398 Decal Identification...

Page 82: ...82 PARTS LIST Decal Identification...

Page 84: ......

Page 85: ......

Page 86: ......