11

866-795-1586 • WWW.SEWERNOZZLES.COM

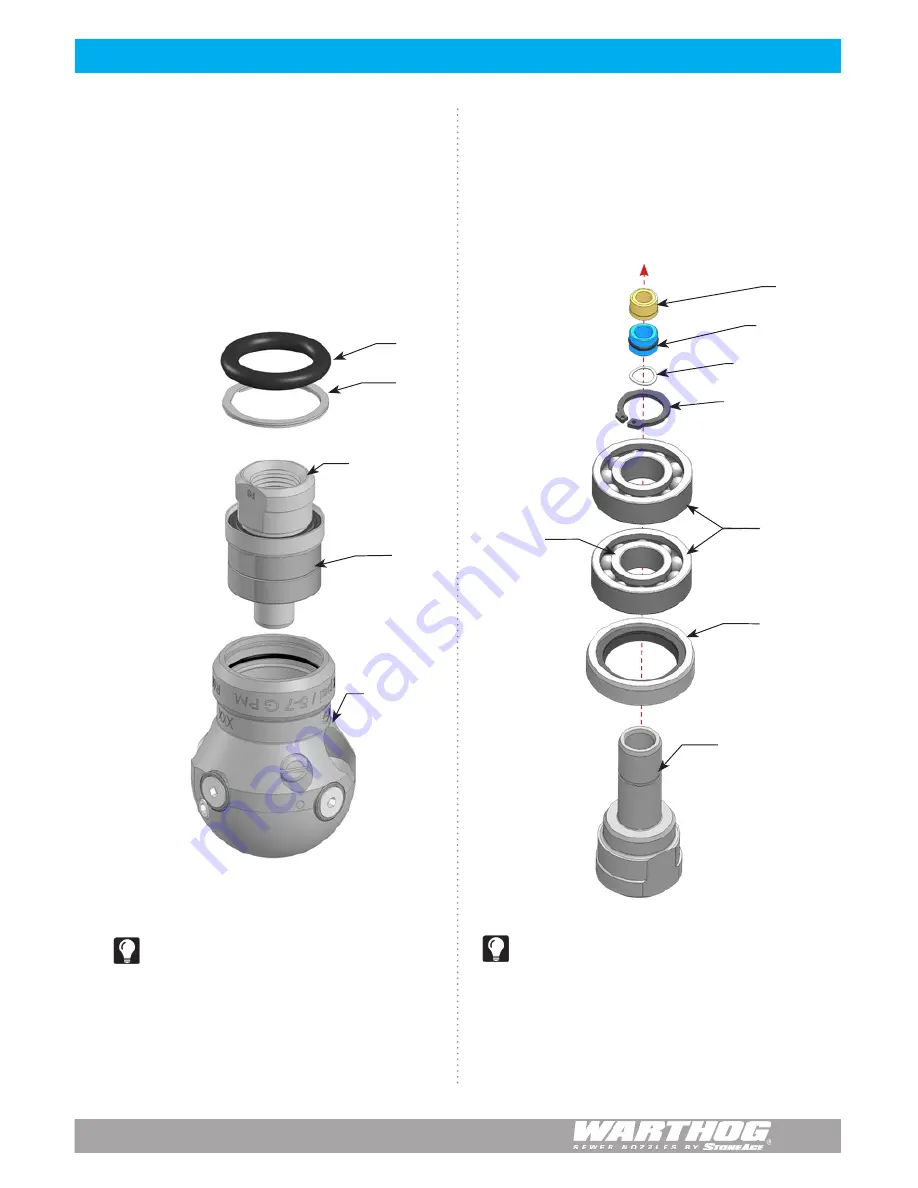

DISASSEMBLY

1. Remove the O-Ring (WT 030) at the rear end

of the Warthog.

2. Remove the Retaining Ring (WT 032) at the

rear end of the Warthog.

3. Pull the Shaft (WT 001-XX) out of the Head

(WT 040). The bearings and other parts will

come out with the Shaft.

4. Remove the Seat (RJ 011-K), H.P. Seal (RJ

012-KTO) and Wave Spring (WT 014) from

the Shaft.

5. Remove the Retaining Ring (WT 033) from the

Shaft. Pull the Shaft out of the Bearings.

6. Remove the Shaft Seal Sleeve (WT 002) from

the Shaft (WT 001-XX).

Figure 1: For Steps 1-3

TECH TIPS:

Use a pick to gently remove

the O-Ring. Use a medium sized flat screw-

driver to pry off the Retaining Ring

TECH TIPS:

Use a pick to gently remove

the Brass Seat and High Pressure Seal. Use

Retaining Ring Pliers to remove the Retaining

Ring. If using an Arbor Press to push the

Shaft out of the Bearings, be sure to set the

bearing down on the inner race and make sure

everything is straight before pressing.

Figure 2: For Steps 4-6

WT 032

Retaining Ring

WT 030

O-Ring

WT 007

Bearings (2)

WT 007

Bearings (2)

WT 002

Shaft Seal Sleeve

INNER

RACE

*WT 040-R24-C

(For WT-1/2 Only)

WT 040-R31-C

WT 040-R45-C

WT 040-R60-C

Head Options

DISASSEMBLY

RJ 011-K

Seat

RJ 012-KTO

H.P. Seal

WT 014

Wave Spring

WT 033

Retaining Ring

(WT-3/8 Only)

WT 001-P6 or

WT 001-BSPP6

(WT-1/2 Only)

WT 001-P8 or

WT 001-BSPP8

Shaft Options

(WT-3/8 Only)

WT 001-P6 or

WT 001-BSPP6

(WT-1/2 Only)

WT 001-P8 or

WT 001-BSPP8

Shaft Options