4

866-795-1586 • WWW.SEWERNOZZLES.COM

RECOMMENDED HOSES

WT-1/2:

StoneAge recommends a 1/2” ID hose be used, especially when using longer hose lengths.

WT-3/8

: StoneAge recommends a 3/8” ID hose be used; if 1/4” ID inch hose is used, too much pressure is

lost (at 5 gpm, each 100 ft of 1/4” hose will take away 700 psi due to friction).

JET AND PLUG LOCATIONS

Jet thrust powers rotation and also pulls the tool through the line. The Warthog® WT can be jetted in

different configurations depending on the application. The front jet is useful for unblocking pipes. The

front jet decreases the pulling power of the rear jets. Plugging the front jet will increase the ability of the

tool to pull itself down the line. A thick viscous fluid inside the tool controls the rotation speed.

Pumps are commonly sold based on their

theoretical

maximum flow output; in reality, none are 100%

efficient. We try to take this into account when supplying you the jets. If you are not getting to the

operating pressure desired, the sizes of the jets may need to be changed.

Warthog® WT

CONFIGURATION INFORMATION

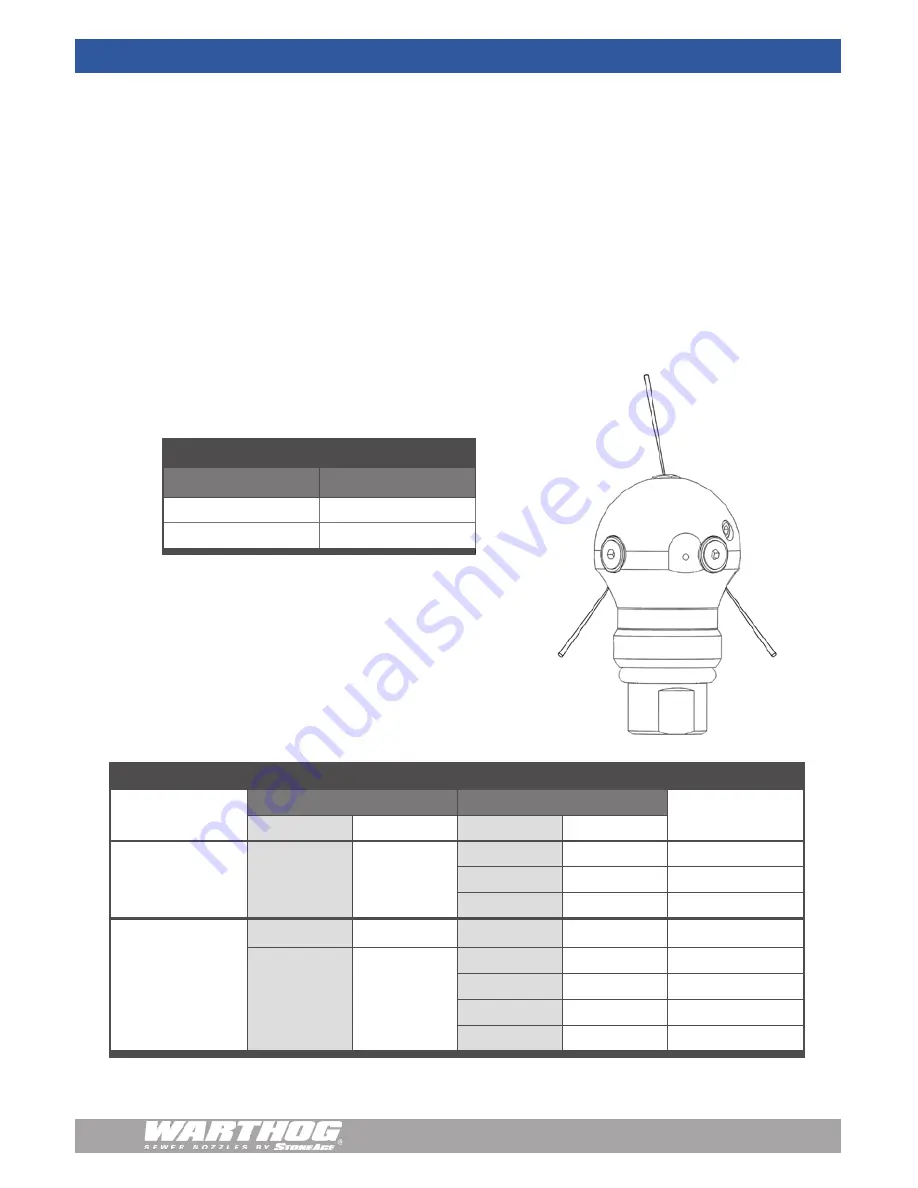

Warthog® WT HEAD OFFSET CHART

MODEL / INLET

CONNECTION

PRESSURE RANGE

FLOW RANGE

HEAD

psi

bar

gpm

lpm

WT-3/8

OR

WT-BSPP6

1200-5K

83-345

9-12

34-45

WT 040-R31-C

7-9

26-34

WT 040-R45-C

5-7

19-26

WT 040-R60-C

WT-1/2

OR

WT-BSPP8

*

1200-4K

83-276

12-21

45-80

WT 040-R24-C

1200-5K

83-345

12-15

45-57

WT 040-R24-C

9-12

34-45

WT 040-R31-C

7-9

26-34

WT 040-R45-C

5-7

19-26

WT 040-R60-C

The table below shows commonly used jet/plug

configurations for the tool.

Warthog® WT JET AND PLUG CHART

15º PORT

150º PORTS

1 x Jet

2 x Jets

1 x Plug

2 x Jets

Jets are Part Number: AP2-XXX

Plugs are Part Number: GP 025-P2SS

Once you have confirmed the required jetting configuration,

use the StoneAge Jetting App to determine jet sizes:

jetting.stoneagetools.com

For more information contact your factory authorized

StoneAge® Inc. distributor or go to;

www.sewernozzles.com

WT

3 Ports:

1 @ 15º

2 @ 150º

15º

150º

150º

*

Operating the WT 040-R24-C at max pressure and flow will over torque the tool.

The max flow can only be achieved by running the tool at 4kpsi (275 bar) less.