2

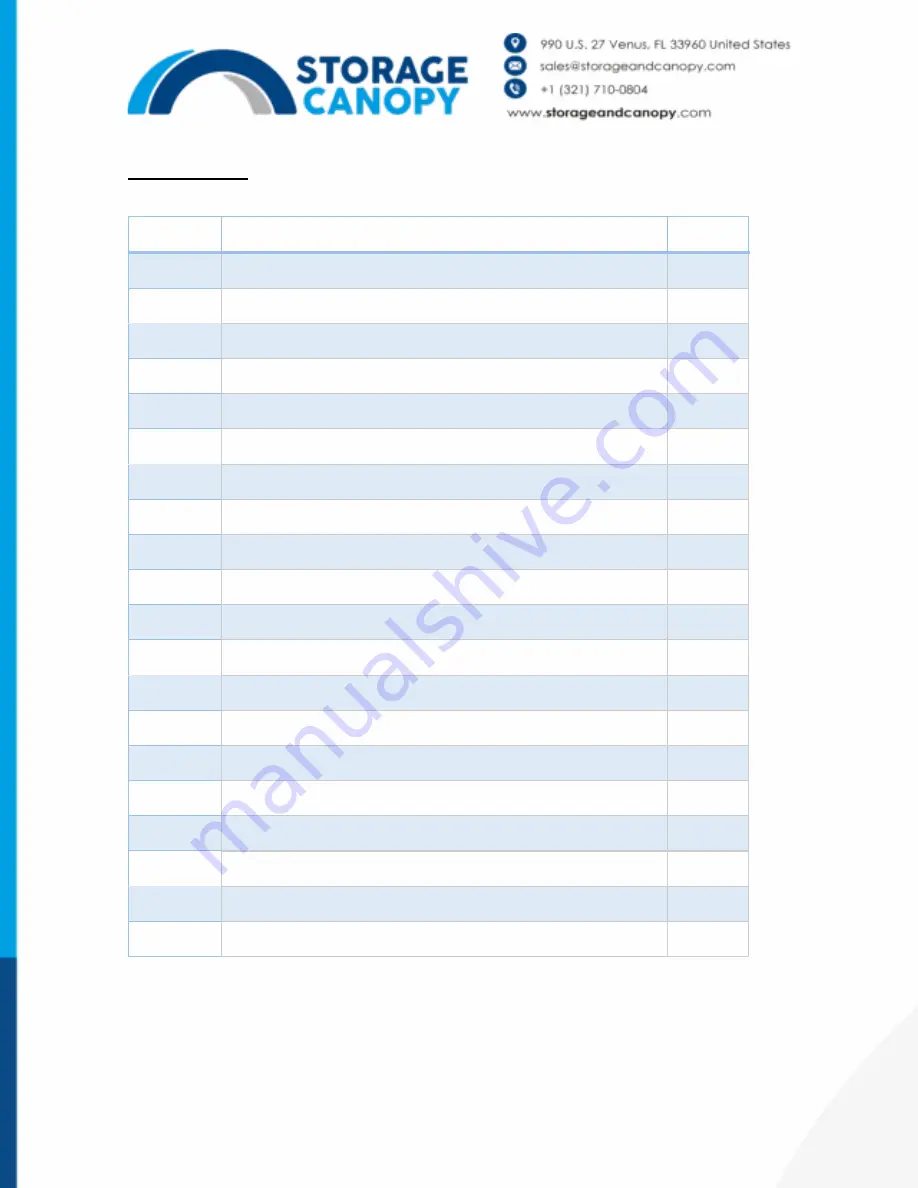

PARTS LIST

Part Code

Description

Qty

L1

Left base plate

10

R1

Rigth base plate

10

1

Roof bent tube

10

2

Upside bent tube

20

3

Underside bent tube

20

4

Lower bent tube

20

5

Purlin

63

6

Inclined support tube

16

7

Clip for inclined support tube

32

8

Bolts M12x100

70

9

Bolts M10x90

160

10

Ratchet

20

11

Nylon band for ratchet

20

12

Angle seats

4

13

Roof cover

1

14

Knitting rope for cover

60

15

∮

32 Plastic plug for end of tensioning tube

4

16

Tensioning tube

2 groups

17

Iron angle for base plate

20

18

Bolt 12x30

60