105

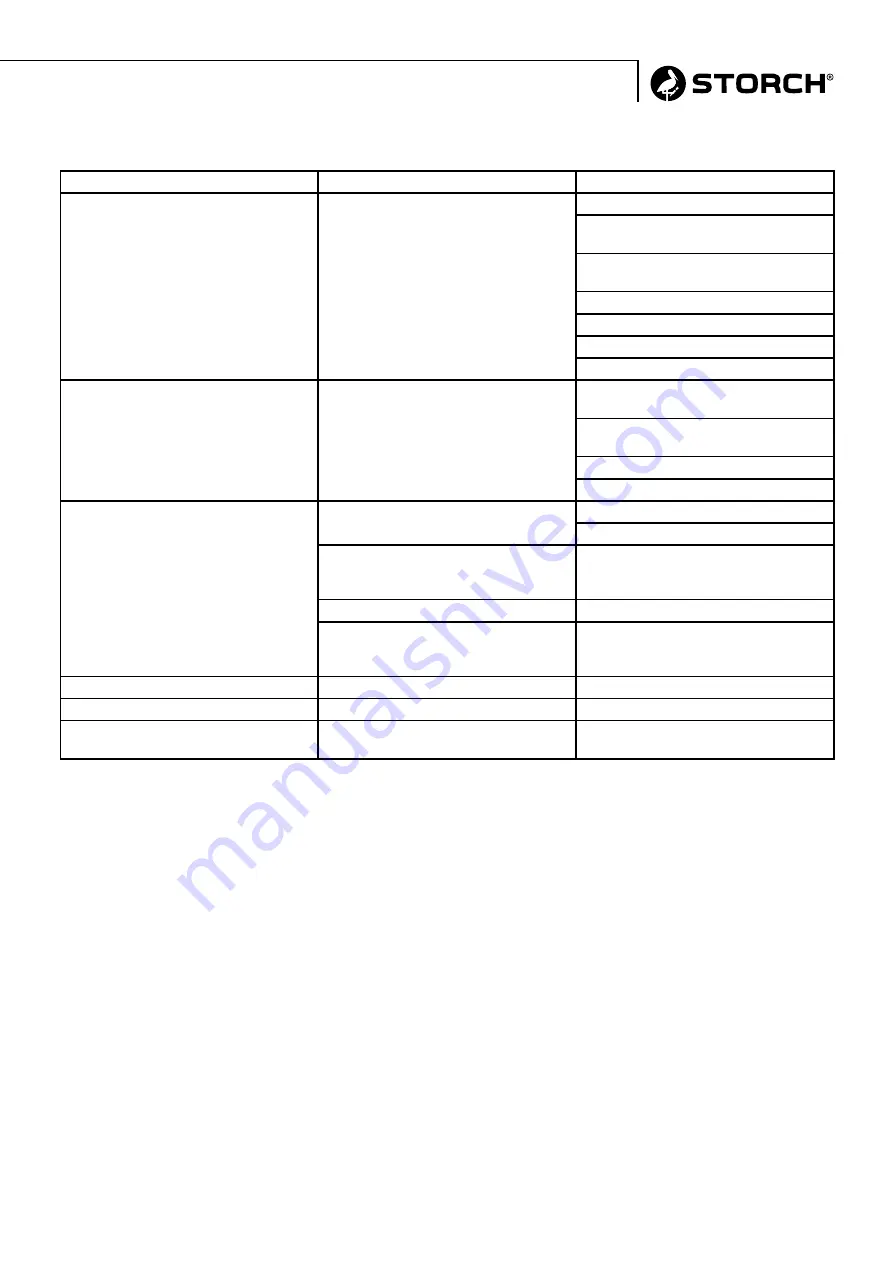

Troubleshooting

Problem

Cause

Remedy

No substance transport

Insufficient amount of coating sub-

stance in the siphon cup, coating

substance excessively viscous, hose

to the non-return valve and/or non-re-

turn valve clogged, air hose not

installed correctly, nozzle too small,

nozzle clogged, gun lid and siphon

cup not connected correctly, cup seal

faulty, vacuum screen on the riser

pipe clogged, connection between

riser pipe and gun body clogged

Top up cup

Check container seal for leaks. If

necessary, tighten lid

Dilute coating substance (see manu-

facturer information sheet)

Replace hose to the non-return valve

Correctly install the air hose

Check for clogging

Filter the coating substance

Spraying device not starting

No power

Check socket outlet. Repeatedly ope-

rate the on/off switch

Connect the mains cable, check for

damage

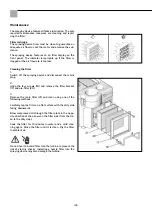

Reset the overload switch (K)

Check the cable drum

Insufficient atomising

Dirty filter

Clean or replace filter as required

Check the filter display control light

Extension cable too long

Use extension cables with protective

earth conductor and a minimum dia-

meter of 2.5 mm

²

, max. length 15 m

Hose too long

Use original air hose

Nozzle too small or coating substance

highly viscous

Use larger nozzle or dilute coating

substance (see manufacturer informa-

tion sheet)

Protect switch triggers

Clogged filter

Clean or replace filter as required

High ambient temperature

Move spraying device to a cooler area

Excessive current consumption

Send to authorised customer service

centre

Summary of Contents for HVLP SmartFinish

Page 23: ...23 ...

Page 47: ...47 ...

Page 71: ...71 ...

Page 95: ...95 ...

Page 119: ...119 ...

Page 143: ...143 ...

Page 146: ...146 ...

Page 147: ...147 ...