132

8. Commissioning

Before you start spraying work, prepare the coating material in line with the manufacturer's instructions (thinning/stir-

ring).

Place the suction pipe in the material container and switch the device on; then turn the pressure regulator button until

the device just starts to run, until the system is ventilated (paint escapes from the ventilation hose).

Hold the gun against the edge of a 2nd bucket, in which the solvent will be caught; pull the trigger on the gun and clo-

se the air valve. Turn the pressure regulator switch a bit further and wait until paint escapes from the gun. The system

is now vented.

Release the trigger on the gun; secure it and fit the nozzle holder and nozzle. Gradually turn the pressure regulator

(approx. 10 bar) until the desired spraying pressure has been reached. This is the case when the spraying pattern is free

of stripes. Excessive spraying pressure unnecessarily creates paint mist.

Eliminating nozzle blockages

Adjusting the pressure

Risk of injection: never hold your hand, your body, your finger or your hand wrapped in a cloth in front of the spraying

nozzle if you are cleaning the spraying nozzle or checking for blockages. Always point the gun at the floor or a waste

bin if you want to check whether the nozzle is free

During spraying into a paint can, always select the lowest spraying pressure and make sure that one metal part of the

gun always has contact with the metal container.

In case of emergency, switch off the spraying device. If you want to interrupt operations with the device in case of

emergency, switch off the motor. Read the depressurisation section.

Turn the pressure regulator button clockwise to increase the pressure or anti-clockwise to reduce the pressure. Always

use the lowest pressure required for full atomisation of the material. If more material output is required, use a larger

nozzle rather than increasing the pressure.

NOTE:

If you operate the spraying device at a higher pressure than needed, this will lead to increased use of material, and

increased wear on the device and nozzle.

NOTE:

Check the spray pattern. The nozzle size determines the width and flow rate of the coating material.

Switch off the device

1. Relieve the pressure (Section 4.).

2. Clean the nozzle and the spray gun as instructed in the separately enclosed operating instructions within the scope

of delivery of the spray gun.

3. Flush the spray gun after use if you work with materials on a water basis or with materials that may harden inside

the spray gun overnight. For this purpose, read the section on cleaning (Section 7.).

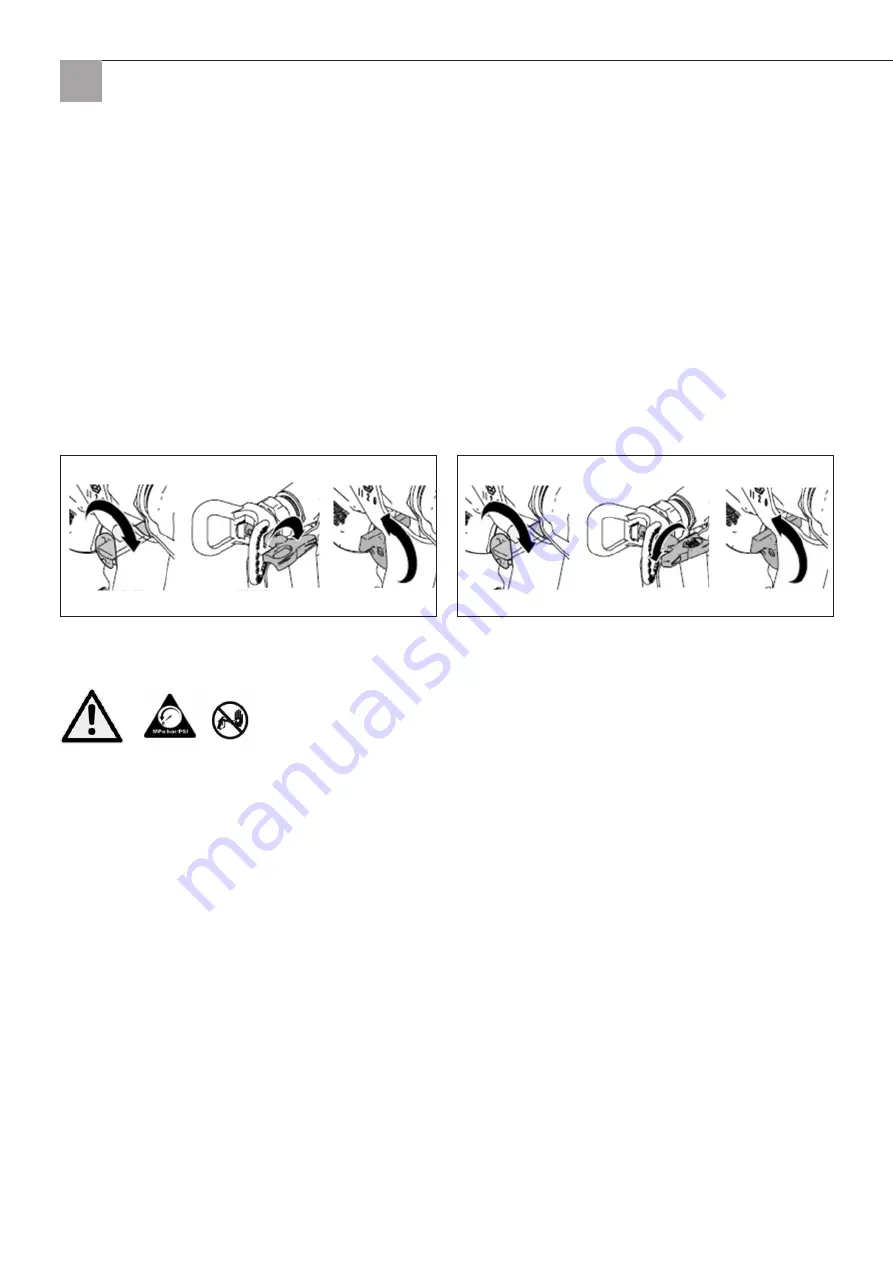

1. Release the trigger. Engage the trigger safety lock.

Reverse the spray nozzle. Release the trigger safety lock.

Pull off the spray gun in the waste section to unclog it.

2. Engage the trigger safety lock. Bring the spray nozzle

to its original position. Release the trigger lock and conti-

nue spraying.

Summary of Contents for LP 400 F

Page 1: ...Airless LP 400 F DE NL FR IT GB CZ ...

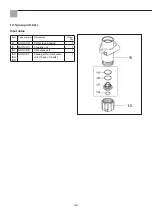

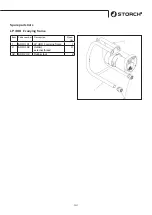

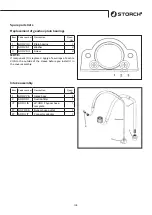

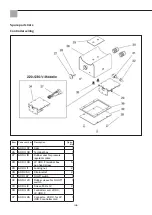

Page 22: ...22 Ersatzteillisten Motor Antrieb ...

Page 52: ...52 Motor aandrijving ...

Page 82: ...82 Nomenclatures de pièces de rechange Moteur entraînement ...

Page 112: ...112 Elenchi dei pezzi di ricambio Motore Azionamento ...

Page 142: ...142 Spare parts lists Motor gearbox ...

Page 172: ...172 Seznamy náhradních dílů Motor pohon ...

Page 182: ...182 ...

Page 183: ...183 ...