134

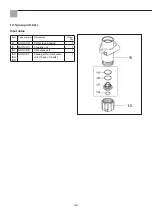

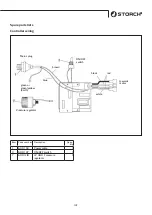

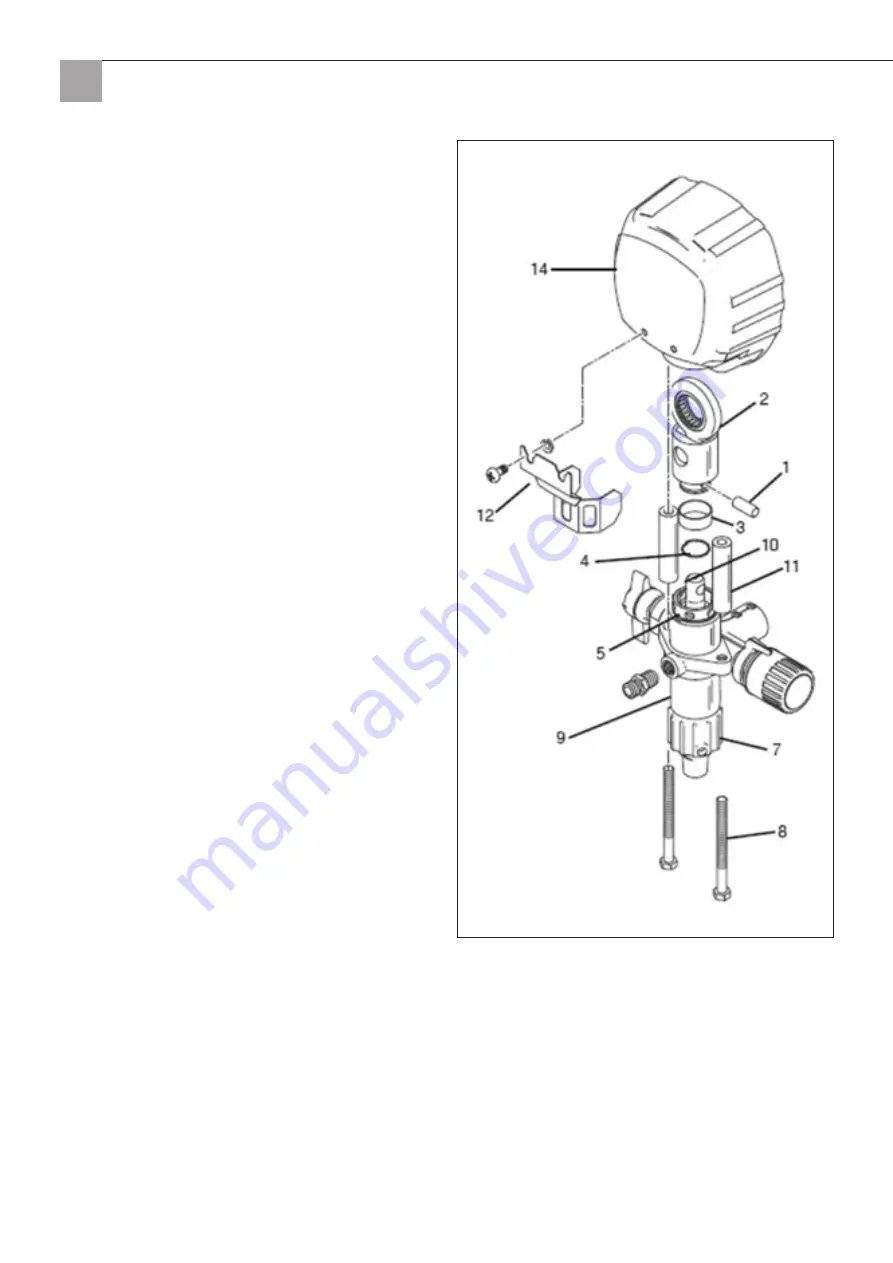

Servicing the fluid pump

Fluid pump removal

1. Relieve the pressure.

2. Flush the spraying material out of the device.

3. Remove the cover (12) on the connecting rod.

4. Move the piston rod (10) to the bottom position by

letting the pump run slowly.

5. Switch off the motor and isolate the device from the

power supply.

6. Remove the circlip (4) from the connecting rod (2)

and push the sleeve (3) downward to expose the pin

(1) on the connecting rod.

7. Remove the suction pipe from the fluid pump (9) by

releasing the valve nut (7) with the packing adjust-

ment tool.

8. Remove the two screws (8) and the cover (14). The

fluid pump (9) is now loosely suspended.

9. Remove the pin (1) on the connecting rod from the

connecting rod (13) so that the fluid pump (9) can be

removed.

Reassembling the fluid pump

1. Loosen the gland nut and make sure that the piston

rod (10) is at the topmost position of the fluid pump

housing. Push the sleeve (3) and the circlip (4) over

the piston rod (10).

2. Push the piston rod (10) upward into the connec-

ting rod (2). Push the pin (1) on the connecting rod

through the connecting rod (2) and the piston. Push

the sleeve (3) upward over the pin (1) on the connec-

ting rod and then push the circlip (4) into the groove

on the connecting rod (2).

3. Push the two pipe spacers (11) between the fluid

pump (9) and the cover (14), and push the two screws

(8) through the spacers; then tighten the screws

evenly (alternately).

4. Re-assemble the lower suction valve group by pla-

cing the seating, the o-ring, the ball and the ball

guide into the valve nut (7) and bolting onto the fluid

pump housing.

5. Re-attach the pressure regulator button on the fluid

pump housing.

6. Start the pump and run it slowly to check whether

the piston rod (10) is correctly set. If needed, adjust

the two screws (8) that hold the cover on the fluid

pump housing. This prevents the piston rod from blo-

cking.

7. Tighten the gland nut clockwise until you feel some

resistance against the disc spring; tighten ano-

ther three quarter turn. The tightening torque of the

packing nut amounts to 2,7 Nm. Fill five drops of

piston oil into the gland nut.

8. Run the pump for a few minutes at full pressure.

Relieve the pressure as described in the section about

depressurization (Section 4.) and then adjust the

gland nut – as shown in step 7 above.

9. Attach the cover of the connecting rod.

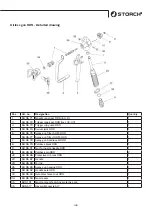

Summary of Contents for LP 400 F

Page 1: ...Airless LP 400 F DE NL FR IT GB CZ ...

Page 22: ...22 Ersatzteillisten Motor Antrieb ...

Page 52: ...52 Motor aandrijving ...

Page 82: ...82 Nomenclatures de pièces de rechange Moteur entraînement ...

Page 112: ...112 Elenchi dei pezzi di ricambio Motore Azionamento ...

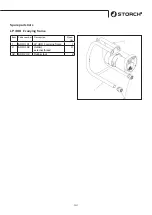

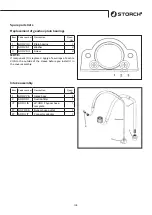

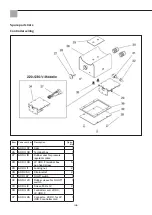

Page 142: ...142 Spare parts lists Motor gearbox ...

Page 172: ...172 Seznamy náhradních dílů Motor pohon ...

Page 182: ...182 ...

Page 183: ...183 ...