StormPro

®

BA

Series

Sump Pump

OPERATION MANUAL

Dated: 02/15/2013

Document Name: StormPro_BASeries_OM

Page 2 of 8

Register your product at www.sumpro.com

WARNING:

The pump can be used for sea

water but not inflammable, corrosive,

explosive or dangerous liquids.

I

nstaLLatIon

Drill a 1/8

″

inch hole into PVC pipe 4 inches above the

pumps discharge.

Do not work on pump until power is unplugged. Do

not cut off ground pin or use an adapter fitting. Do not

use an extension cord.

The pump power cord should be connected to a

separately fused, grounded line with a minimum

capacity of 15 amps.

It can be connected to non-fused breaker at the

recommended amperes. Never touch the pump when

it is connected to electrical power.

1.

Before installing or servicing this pump, be

certain pump power source is disconnected.

2. Installation and electrical wiring must adhere to

state and local codes and must be completed

before priming pump. Check appropriate

community agencies or contact local electrical

and pump professionals.

3. Call an electrician when in doubt. Pump

should be connected to a separate 15 amps

circuit breaker or 15 amp fuse block. Note that

plugging into existing outlets may cause low

voltage at motor, causing blown fuses, tripping

of motor overload, or burned out motors.

4. A permanent ground connection from pump

to the grounding bar at the service panel is

mandatory, StormPro

®

sump pumps come

with a grounding conductor and a grounding-

type attachment plug. Do not connect pump to

a power supply until permanently grounded.

For maximum safety, connect pump to a circuit

equipped with a fault interrupter device when

you position the pump’s grounding wire.

5. Voltage of power supply must match the voltage

of the pump.

6. Piping: Plastic PVC pipe could be installed in the

outlet piping, but drain hose, galvanized steel or

copper pipe may be used if desired. All piping

must be clean and free of all foreign matter to

prevent clogging. Use thread compound on

all threaded joints unless specified otherwise.

Be sure to seal the thread connection with

tape when using the pipe fitting to connect the

flange.

7.

Before installing pump, clear sump basin of any

water, debris or sediment.

WARNING:

Sump basin must be vented in

accordance with local plumbing codes.

StormPro

®

sump pumps are not designed for, and

can not be installed in locations classified as

hazardous.

8.

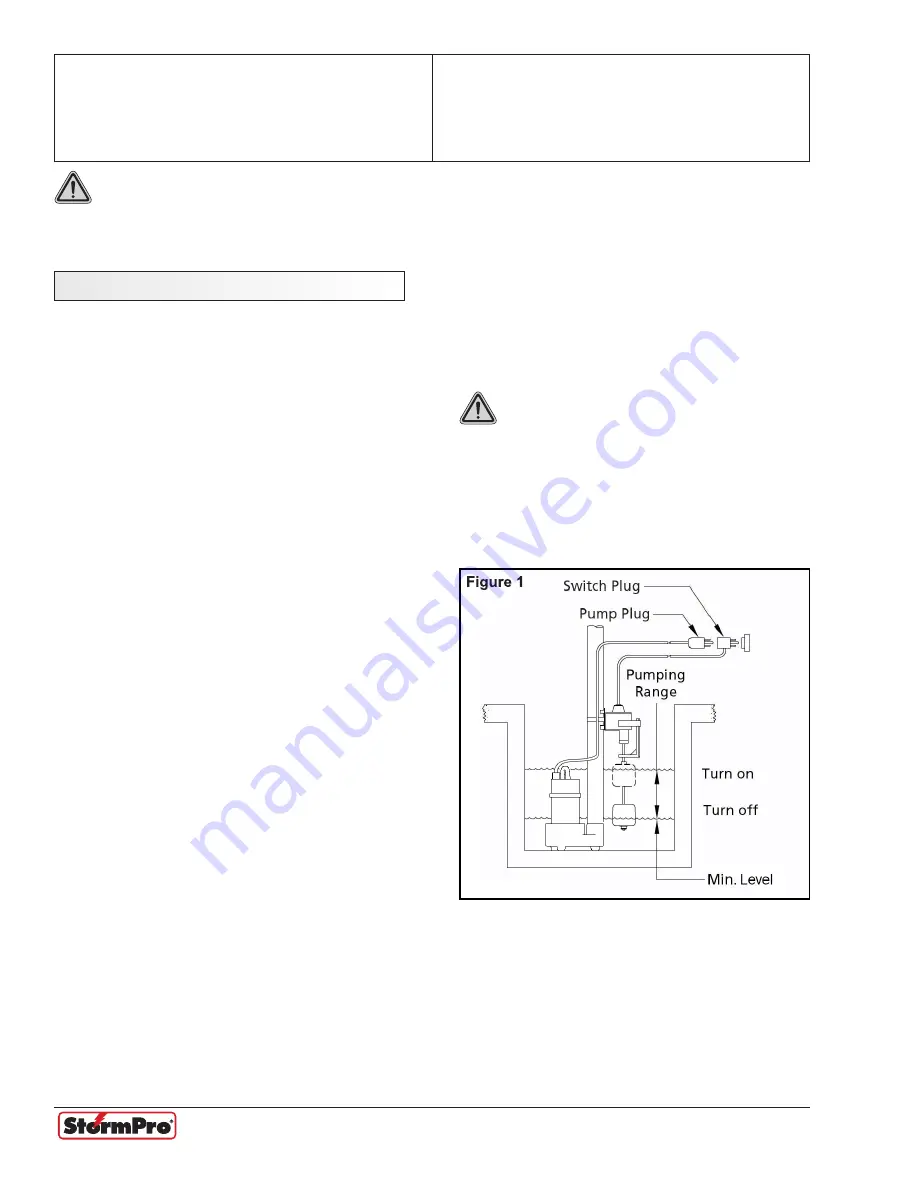

Position vertical switch on discharge pipe,

making sure that off level is not lower than

minimum level.

See Figure 1.

Note:

If you purchased your pump with an Ion

™

Digital

Level Control switch, please refer to its manual for

installation instructions.

9. Tighten pipe clamp around pipe and through

mounting bracket slots.

10.

If needed, on and off stops on switch can be

adjusted.

See Figure 1.