CleanStation™ CSIIP Installation Guide

DOC-03204 Rev. B

6

3 Installation

3.1 Required Items

Prepare the following:

• protective glasses

• utility knife

• strap cutter

• scissors

• Phillips screwdriver

• 14-mm socket wrench

• 3.2-mm hex (Allen

®

) key

3.2 Unpacking the CleanStation™ CSIIP

To unpack the unit:

1. Check the shock detector label to ensure that the package has not been

damaged.

2. Make sure that the package has been moved as close as possible to its final

location.

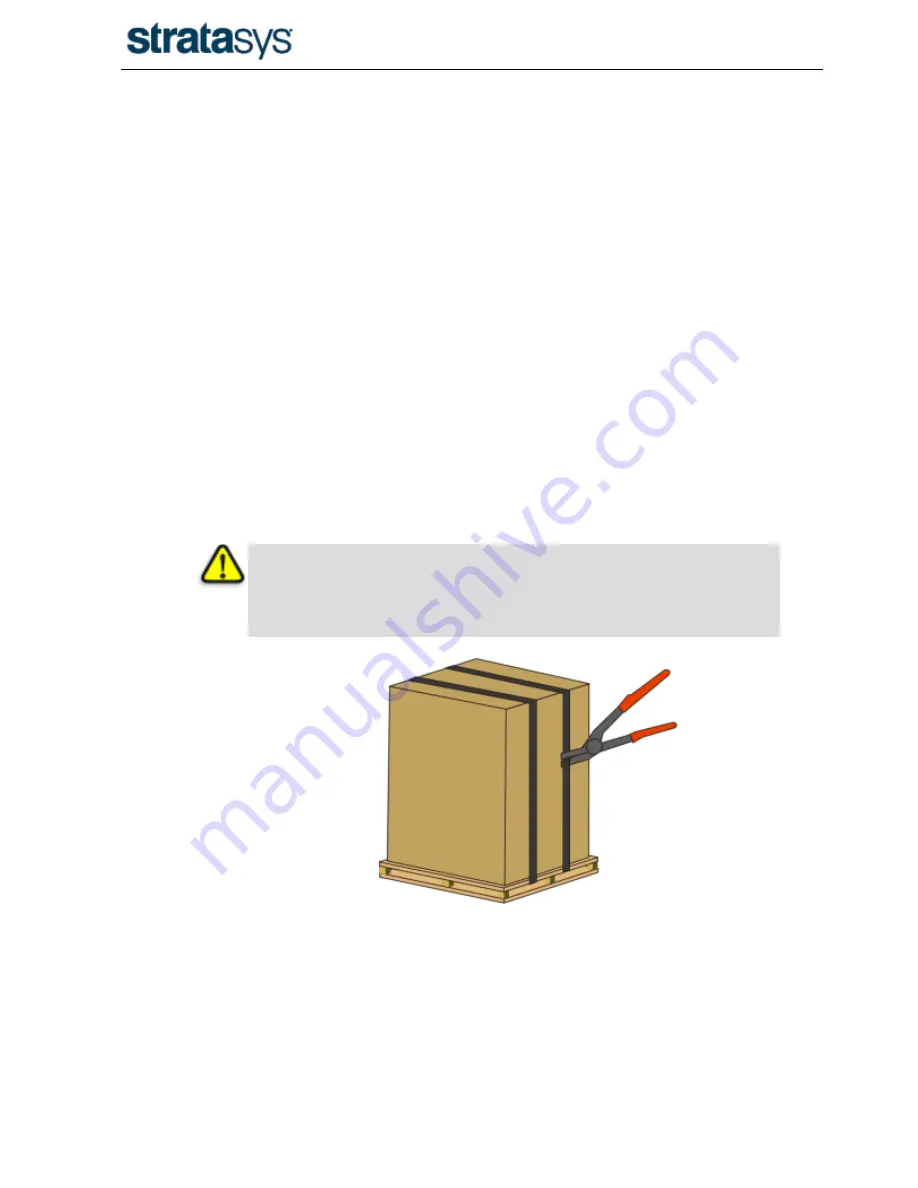

3. Using strap cutters, carefully cut the straps around the package.

Warning: Impact hazard.

The straps are tightly wrapped around the package and can cause injury

when suddenly released. Stand clear of the straps while cutting them.

Figure 1 Cutting the straps