INSTALLING ACCESSORIES

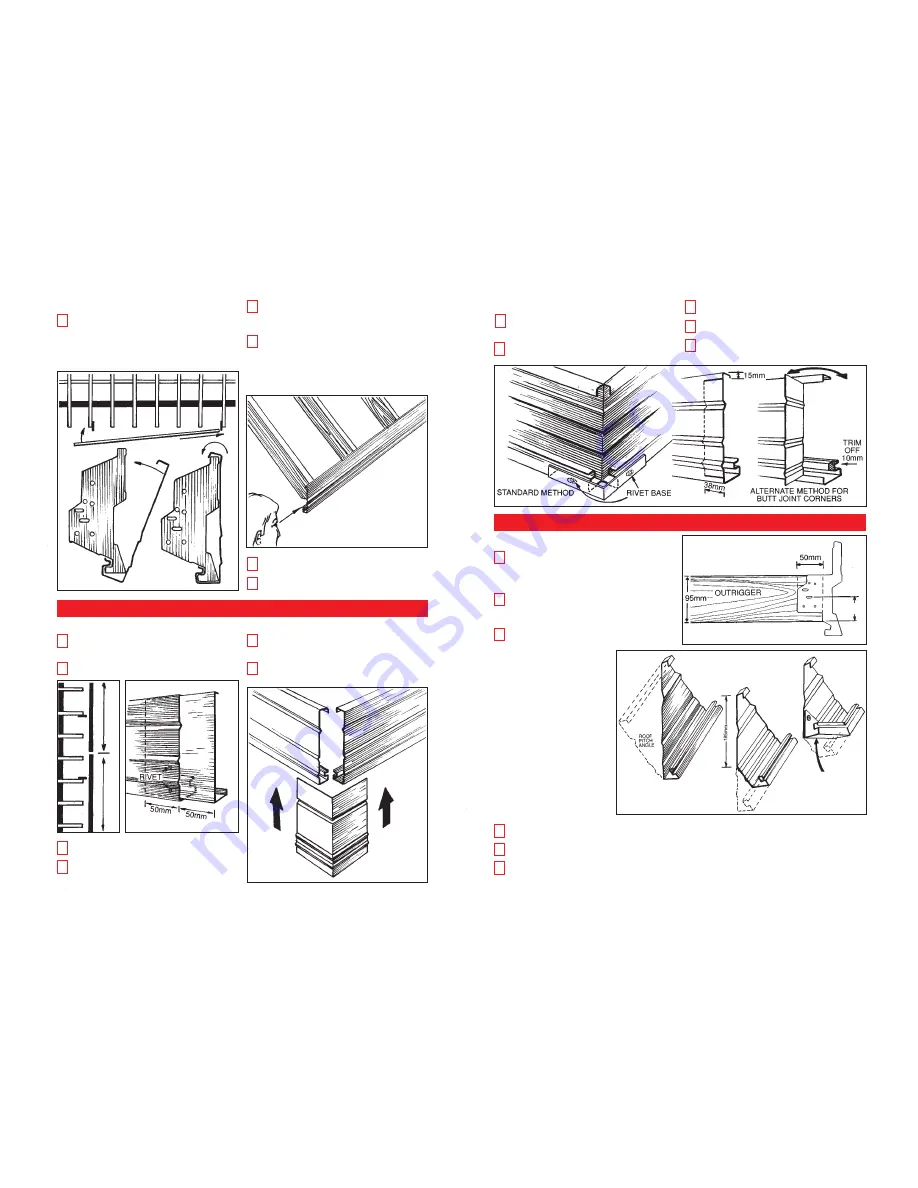

INSTALLING FASCIA AS BARGE

FASCIA INSTALLATION

Slide the fascia onto one of the two brackets fixed

(see 5 above).

▫

Clip the base of the fascia into the second bracket.

▫

Stretch the top of the fascia over the top of the

bracket. In some cases, fascia can be simply slid

over the second bracket.

At the centre point of the run, insert a bracket into

the fascia and then fix the bracket to the set up

point previously marked (Step 7 previous page) with

a nail in the centre slot only.

Check the fascia for straightness (by eye) by

looking along the base of the fascia (also check

with spirit level to base of fascia). When straight, fix

every second rafter to the set up lines marked, again

using the centre slot and now utilizing one of the

base holes. Ensure that the base of the fascia

stays straight.

1

MARKING OUT

On the barge rafter bracket, the centre slot is set

52 mm from the base of the outrigger and the

back of the bracket is set in 50 mm from its end.

FIXING BRACKETS

Fix only two brackets as previously described

using three nails on each side of gable.

INSTALLING

The first length of barge to be installed must first

have the lower end made to fit the fascia.

This is done by:

▫

Marking on the front of the

barge the roof pitch and then cut

off.

▫

On the cut edge, mark down

185 mm, and then draw a line at

90˚ from the base to intersect this

point, then cut this off.

▫

On the cut edge, mark a line at

90˚ at the intersection of the two

previous steps. This line will go to

the base of the fascia.

▫

Cut along the line marked in the

previous step. Also cut excess

metal from below soffit groove

(trim this groove to length if

needed). Push upwards and rivet.

Attach barge as previously described for fascia.

Attach barge mould as per external mitre (remember that the long leg of the barge mould fits on the

fascia. Both left hand and right hand barge moulds are available).

Install remaining barge rafter brackets.

1

1

1

2

3

4

JOINING SLEEVES

Where a joining sleeve is required, do not fully

nail standard rafter brackets for at least two

rafters adjacent to the join.

Rivet the joining sleeve to one length of fascia

as shown.

1

2

Slide the second piece of fascia over the joining

sleeve and rivet.

Check that the fascia is straight by sighting

along the base of the fascia and nail the

remaining brackets.

3

4

EXTERNAL MITRES

Slide the external mitre over the adjoining fascia

and check that the fascia has not been pulled out

of line and that the corner remains square.

Rivet the external mitre at the 'dimples' embossed

in the mitre. Recheck for square and alignment.

1

2

2

3

INTERNAL MITRES

Measure the fascia from the inside of the nearest

external corner or joining sleeve to the proposed

position of the internal mitre.

Cut the top lip of the fascia and the base with a

hacksaw and bend to 90˚.

Fix the fascia to the brackets on the long run in

the same manner as previously described.

Ensuring that the internal corner remains at 90˚,

fix the rafter brackets to the short run of fascia.

Attach the internal corner with rivets as shown.

Note that the alternate butt joint method still

requires an internal corner mitre.

1

2

3

5

4

Finish nailing all marked brackets and then all

brackets not previously installed.

Install hip rafter brackets remembering to fold the

top tag over the rafter and nail.

4

5

52mm