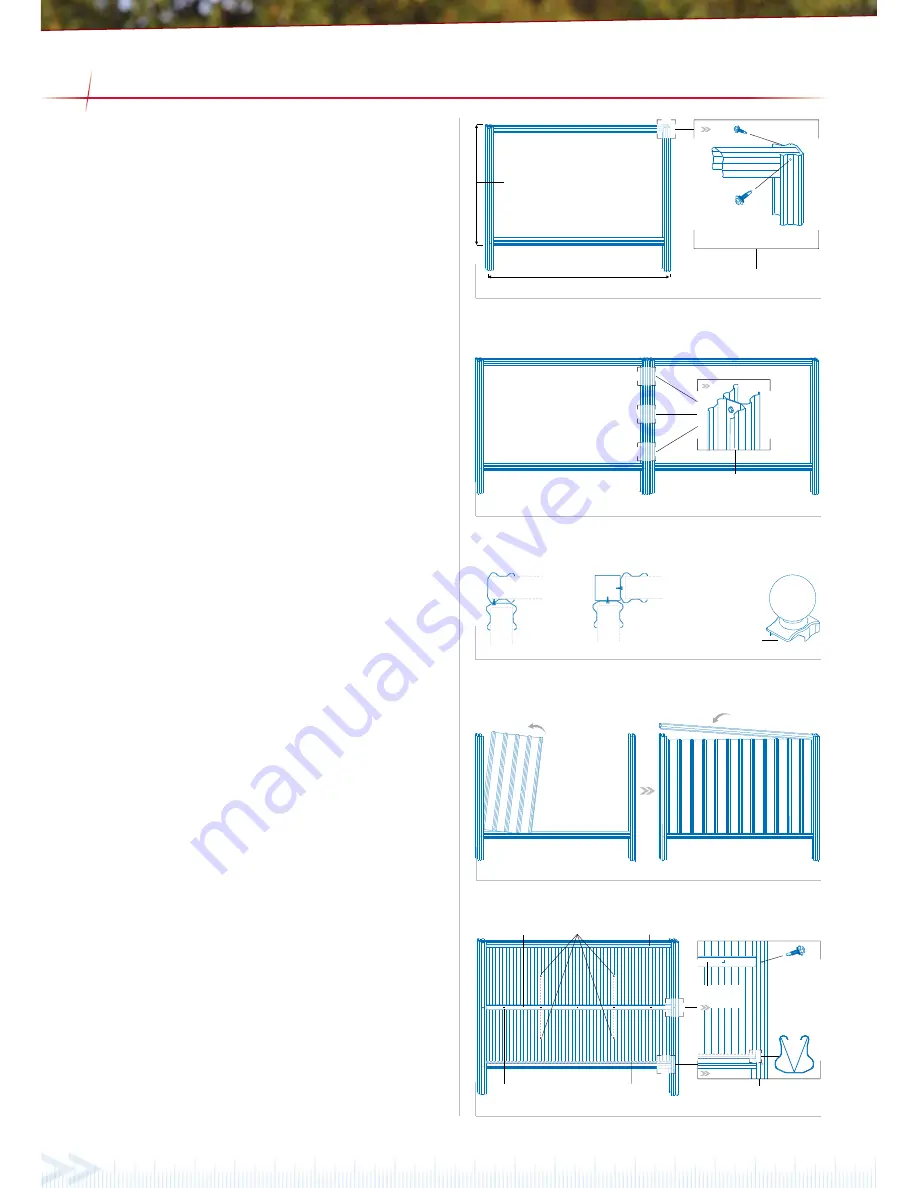

10x16mm

Self-drilling

screw

V-shaped

flashing in

CGI Mini track

38x25mm

rail

Fixing detail

Panel Height

Top Track

Bottom Track

Panel Width

Post

10x16mm

Self-drilling screw

Corner detail

Post fixing detail

Refer to Design Guide

Rotate sheet into position

Press top track into position

5 ripple self-drilling screws

V-shaped flashing

V-shaped flashing

38x25mm rail

four 3mm rivets

10x16mm

Self-drilling

screw

V-shaped

flashing in

CGI Mini track

38x25mm

rail

Fixing detail

Panel Height

Top Track

Bottom Track

Panel Width

Post

10x16mm

Self-drilling screw

Corner detail

Post fixing detail

Refer to Design Guide

Rotate sheet into position

Press top track into position

5 ripple self-drilling screws

V-shaped flashing

V-shaped flashing

38x25mm rail

four 3mm rivets

Notch cut

into ball cap

to sit on

corner post

Fixing corner

with SHS post

Fixing

corner

posts

10x16mm

Self-drilling

screw

V-shaped

flashing in

CGI Mini track

38x25mm

rail

Fixing detail

Panel Height

Top Track

Bottom Track

Panel Width

Post

10x16mm

Self-drilling screw

Corner detail

Post fixing detail

Refer to Design Guide

Rotate sheet into position

Press top track into position

5 ripple self-drilling screws

V-shaped flashing

V-shaped flashing

38x25mm rail

four 3mm rivets

10x16mm

Self-drilling

screw

V-shaped

flashing in

CGI Mini track

38x25mm

rail

Fixing detail

Panel Height

Top Track

Bottom Track

Panel Width

Post

10x16mm

Self-drilling screw

Corner detail

Post fixing detail

Refer to Design Guide

Rotate sheet into position

Press top track into position

5 ripple self-drilling screws

V-shaped flashing

V-shaped flashing

38x25mm rail

four 3mm rivets

FENCE INSTALLATION

Figure 3.0

Fence panels should be installed starting from a gate post, free

end or corner. If you are working on sloped ground and intend to

step or slope the fence see the sections on the following page for

the correct installation procedure.

Assemble the framework

Lay the posts down on the ground and insert the top and bottom

track. Fix the tracks using a 10x16mm screw on each side of

both ends, see Figure 3.0. The top track should be flush with

the top of the post, unless you are installing a screen top, in

which case the post will need to extend 300mm past the track. If

SHS posts are required, they should be fixed to the fence at this

stage using three 10x16mm screws. Caps should be inserted on

top of the SHS posts to prevent water entering. When extending

from a concreted gate post the frame will need to be assembled

vertically in position.

Extending the fence

Assemble the second panel and fix it to the first using three

10x16mm self drilling screws, refer to Figure 3.1. Place the

fence into the footing holes. If you are using SHS posts, ensure

they are installed between the panels. Prop the fence into the

correct position and concrete the joined posts into place. Refer

to ‘Preparing Footings’ for the correct method of concreting

the posts. Frames should be assembled and added one at time,

concreting the footings as you install each frame.

When joining around a corner, the posts can be fixed directly to

each other or both posts fixed to an SHS coloumn, refer to Figure

3.2. The SHS method must be used if the design calls for the

panels to have SHS posts. Post caps and ball caps can be used on

a corner post, provided the bottom of the cap is cut to fit on one

end, so the cap can sit flush.

Installing the sheets

After the concrete has been allowed to cure for at least 48 hours

the fence sheets can be installed. Working on one panel at a time,

take off the top track by removing the screws holding it in place.

The sheets can now be positioned in the frame. Each sheet should

be rotated into position as shown in Figure 3.3, ensuring the

correct sheet overlap. (refer to Figure 3.5) The top track can now

be reinstalled. Starting at one end and working down to the other,

push the track into position, making sure the track is firmly in

place. To minimise rattling, the sheets should be fixed together

at the overlaps using a 3mm rivet midway up the sheet. In wind

speeds W41 and greater, fasten the sheets to the tracks at each

of the overlaps using 10x16mm screws.

Completing a CGI Mini Panel

For CGI mini, two V-shaped flashings are provided. The V-shaped

flashings slide into the tracks with the point of the ‘V’ to the

outside of the panel. A 38x25mm internal rail is installed on one

side. The rail is positioned in the gap between the sheet and post,

half way down the panel. Angle the rail into position and fix the

rail to the post using a 10x16mm screw at each end. The sheets

are then fixed to the rail using five 10x20mm ripple self-drilling

screws per sheet ensuring it is fastened at each overlap. Sheets

should be fixed together at the overlaps using four 3mm rivets

midway between the tracks and internal rail, see Figure 3.4.

Figure 3.3

Figure 3.2

Figure 3.1

Figure 3.4