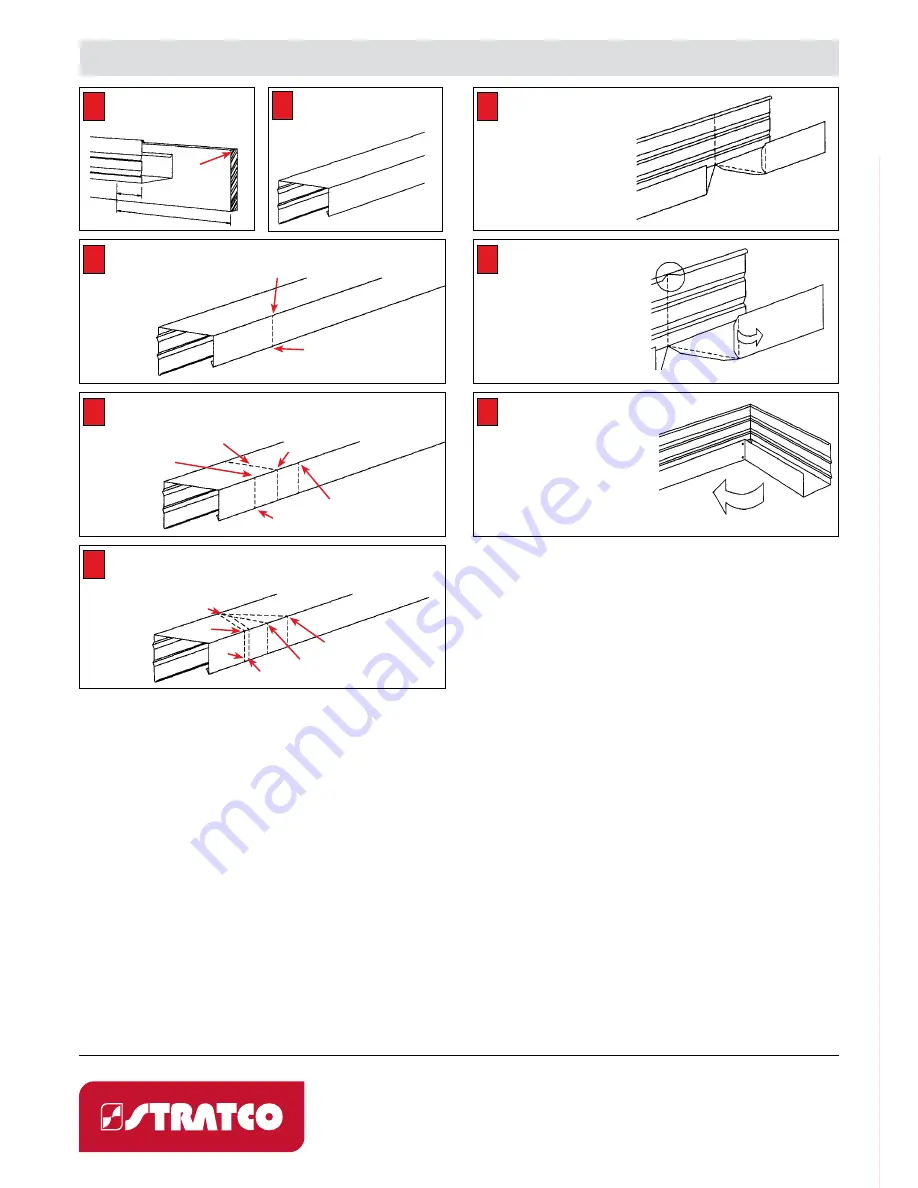

TO MAKE A GUTTER MITRE

Measure fascia from the corner

of the fascia to existing gutter

allowing 100mm for gutter lap.

1

Place length of gutter upside

down on the ground so that the

base of the gutter is facing you.

2

Mark where the fascia corner will

occur (point

A

) on the back of

gutter, and using a 90˚ square

and pencil, draw a line across the

outside of the back of gutter.

3

On the back of the gutter place a further 2 marks, each equal to the width of

the gutter (at points

B

and

C

) to extend beyond the fascia corner. The central

mark

B

should be extended completely around the outside of the gutter using

the 90

˚ square and pencil.

4

On the base of gutter, draw a line to connect the continuous line from

B1

to

both

A

and

C

. Mark a line 10mm away from, but parallel to

A-B1

, and extend

this across the back of the gutter. This will produce a “lap” when the gutter

mitre is formed. This parallel line should

also extend up the back

of the gutter to

A1

.

5

Using tinsnips, cut along the

line on one side and on the

other side, cut on the parallel

line which is 10mm in from the

original line drawn connecting

A-B1

. You will cut out the

complete V marked into the gutter.

In addition, remove excess

material at

A

and

B1

to allow the

outside of the gutter to fold easily,

and the tags to overlap.

6

For a square gutter cut a 45˚

notch into the bead of the

gutter using a hacksaw and

tin snips at

B1

directly in line with

the point of the V on the base of the

gutter. For gutters with an external

bead, such as quad (D) or OG, a

single hacksaw cut is used to cut the

bead. A mitre gusset must then be

attached to complete the bead line.

7

Fold the gutter around until the back

sections touch each other. Fold tag

inside the back gutter. Rivet and

silicone. You have produced an external

gutter mitre. To produce an internal

gutter mitre, reverse your V line marks on

the gutter so that point

B1

is exchanged

for point

B

and the face of the gutter is

cut out not the back. Then follow the

above steps. With some gutters a mitre

gusset will be required to cover any gap in

the gutter bead.

8

B1

B1

A

A

A1

A

B

B

A1

A1

A

C

10mm

C

COMPLY WITH REGULATIONS

All building work must be carried out in accordance with the Building Code of Australia (BCA).

This code refers to various Australian Standards, which provides acceptable standards of

product manufacture and building practice. These include:

• AS/NZ 3500.3 Plumbing and Drainage, Stormwater Drainage

• AS/NZS 3500.5 National Plumbing and Drainage, Domestic Installations

Prospective users of Stratco materials should first ensure that they understand these

requirements and any other state or territory specific regulations that may apply. In some

states of Australia (eg. NSW and Victoria) work involving the installation of roofing, rainwater

goods and drainage may need to be installed by a suitably qualified tradesperson, and comply

with statutory warranties. (Refer www.deus.nsw.gov.au/water/plumbing.asp)

Care should also be taken in the design and installation of roof drainage systems given the

wide range of factors such as rainfall intensity, gutter capacity and selection, number and

placement of downpipes and sumps. Care should also be taken to select the most suitable

gutter style. Gutters that have a front higher than the back are popular to hide the exposed

ends of roofing, but unless manufactured with optional slots or fixed with the bead lower

than the top of the fascia may contravene building regulations. Other fixing options can be

used to eliminate overflow from the back of a gutter into a building. These include additional

overflow weirs placed either in the gutter or stop end, rainheads with overflow weirs, custom

back flashings, leaving a gap between the fascia and gutter back, or other proprietary systems

or trade solutions.

Up to date information about Stratco products, spans, installation requirements and technical

advice can be found on our website at www.stratco.com.au and it is advisable to obtain current

information prior to ordering any materials. If additional information is required contact the

Stratco office in your state.

REMEMBER TO

• Waterproof each rivet with silicone sealant applied on the “weather” side.

• The minimum fall of guttering to the downpipe end is 1 in 500 (or 12mm every 6m).

CONTACT

1300 165 165

www.stratco.com.au

All brands and logos/images accompanied by ® or ™ are trade

marks of Stratco (Australia) Pty Limited.