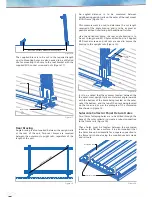

Strap trimmed to

shorter length

Strap fixed with

two Hex head

self-drilling screws

600

mm

600

mm

700

mm

Figure 8

Figure 9

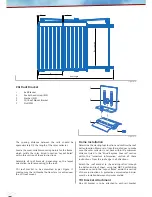

Roof Mount Tilt Kit Preparations

Measure the available mounting area to confirm frame

orientation. Solar collectors are to be mounted in a

portrait orientation only.

Determine the best orientation of the array to satisfy the

following requirements:

•

Requirements of equator direction and tilt angle.

•

Maximise space for the number of solar collectors.

•

Mounting frame attachment to roof rafters and

battens.

•

Tilt frame bracing points.

•

Roof obstructions, chimneys, skylights, etc.

The rail length can be calculated using the following

equation.

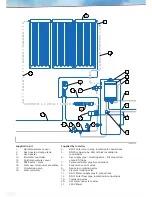

A = Width of the Solar Collector (700mm)

Q= Number of solar panels to be mounted to the rail

RAIL LENGTH = (QxA) + (50x2) + ((Q-1) x24)

Example;

RAIL LENGTH = (4x700) + (50x2) + ((4-1)x24) = 2972mm

The roof members must be inspected and be of suitable

type and in sound condition.

Layout Rules

•

Maximum roof height limited to 10m.

•

Connections to be made down to existing roof

structure, through the roof batten into the rafter, or

at a maximum spacing of 150mm from the rafter.

It is the builder’s responsibility to reinforce the

connection between the roof batten and the rafter.

•

Maximum overhang of the rail from the bracket

attachment to the house rafter is 400mm.

•

Minimum of 2 screws per bracket into the house roof

for timber and steel frame housing. Refer to note for

additional information regarding connection of roof

mount tilt frames in Region B.

•

The maximum distance between mounting brackets

is 1500mm in Region A, 1200mm for timber trusses

and 1500mm for steel trusses in Region B.

NOTE:

In Region B, Terrain Category 1, where roof mount

tilt kits are attached to steel framing, the steel framing

rafter spacing is limited to maximum 1200mm.

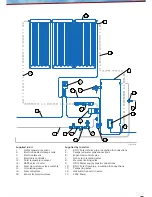

Regulations & OH&S

Before starting construction and installation the installer

should ensure they have read the “Important Information”

section of these instructions and are familiar with

the relevant standards, OH&S regulations and safety

precautions.

Double check all dimensions, levels and bolting locations

before cutting, screwing or bolting structural members.

It is the builder’s responsibility to ensure the existing

house structure is adequate to take the additional loads

of the SolarCore

TM

Hot Water System, and that the persons

erecting the structure have had some previous building

experience because some modifications to the existing

house structure are required.

Attach to an Existing Structure

The builder or council is to ensure the existing house/

structure is limited to a roof height of 10m, and of a

suitable structural integrity that complies with all the

relevant Australian Building codes and standards.

For more information regarding the suitability of the

house structure to accommodate the solar collectors

and mounting frame, consult a structural engineer or a

building authority.

It is the builders responsibility to ensure that the existing

house roof structure is strengthened correctly.

Planning Preparation

The portrait orientation of the solar collector array is to

be mounted facing the equator and tilted at an angle

equal to the sites latitude, from horizontal.

The solar collectors are not to be partially or fully shaded

by surrounding obstructions.

All mounting brackets must be fixed to the existing roof

rafter, or at a maximum distance of 150mm from the

rafter, through the roof batten.

INSTALLATION PROCEDURE - ROOF MOUNT TILT KIT