Page 5

23/03/01

ASSEMBLY INSTRUCTIONS FOR: Ca 7s / BCa 7s

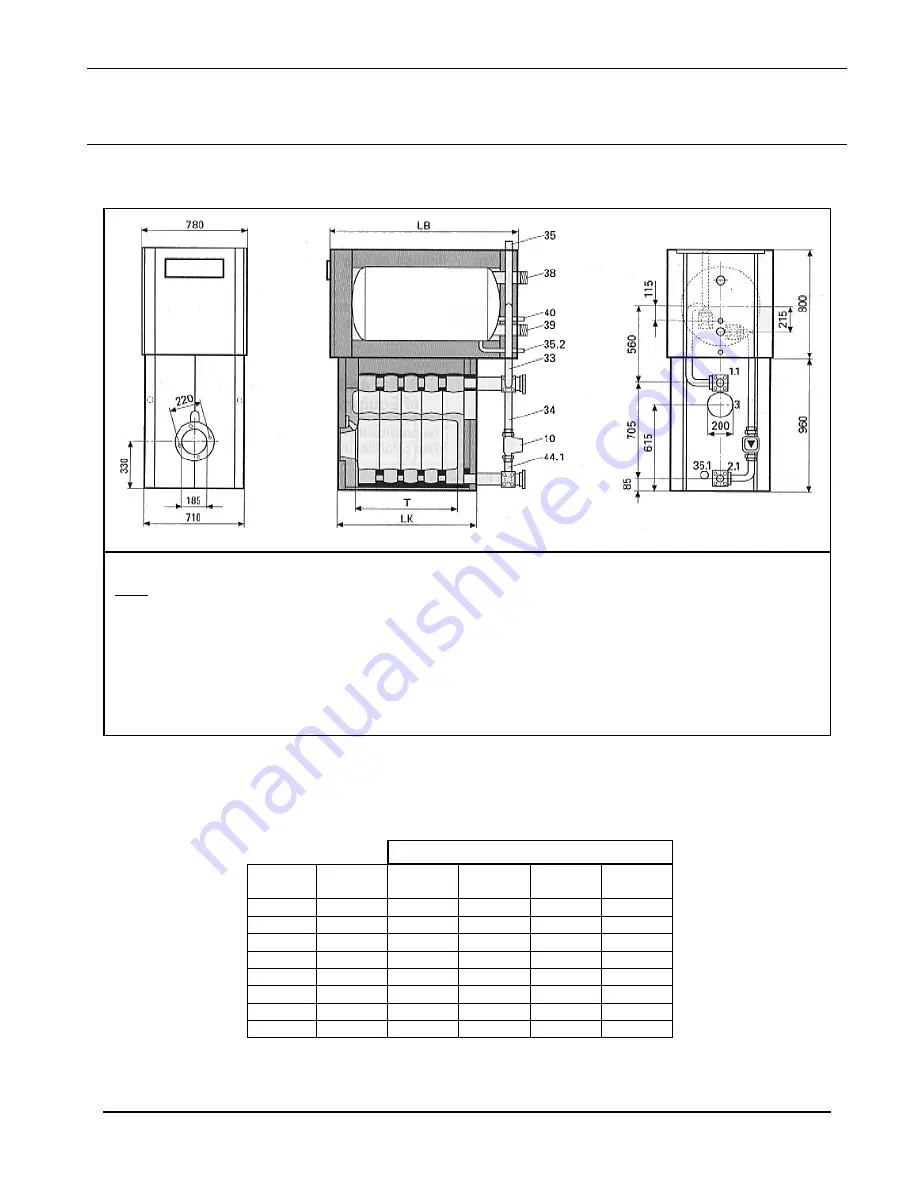

BCa 7s - Dimensions

LK Calorifier Type CSH-

Boiler

240S

300S

360S

500S

LK mm

mm

mm

mm

mm

Ca7s-4

865

1175

Ca7s-5

1015

1175

1475

Ca7s-6

1165

1475

1625

Ca7s-7

1315

1475

1625

2075

Ca7s-8

1465

1625

2075

Ca7s-9

1615

2075

Ca7s-10

1765

2075

1.1 Boiler flow 130mm NW65

2.1 Boiler return 130mm NW65

10 Primary pump 1x230V 1¼”

33

Primary connection pipe (1¼”*) 1½”

34

Return connection pipe (1¼”*) 1½”

35

Air vent 3/8 “

35.1 Boiler drain off ¾”

35.2 HWS drain off ¾”

38

HWS water connection flow (1½”*) 2”

39

Cold water connection (1½”*) 2”

40

Circulation connection ¾”

44.1 Non return valve

* Available for calorifier CSH 240S

KEY: