ASSEMBLY INSTRUCTIONS FOR:

Page 20

11/07/00

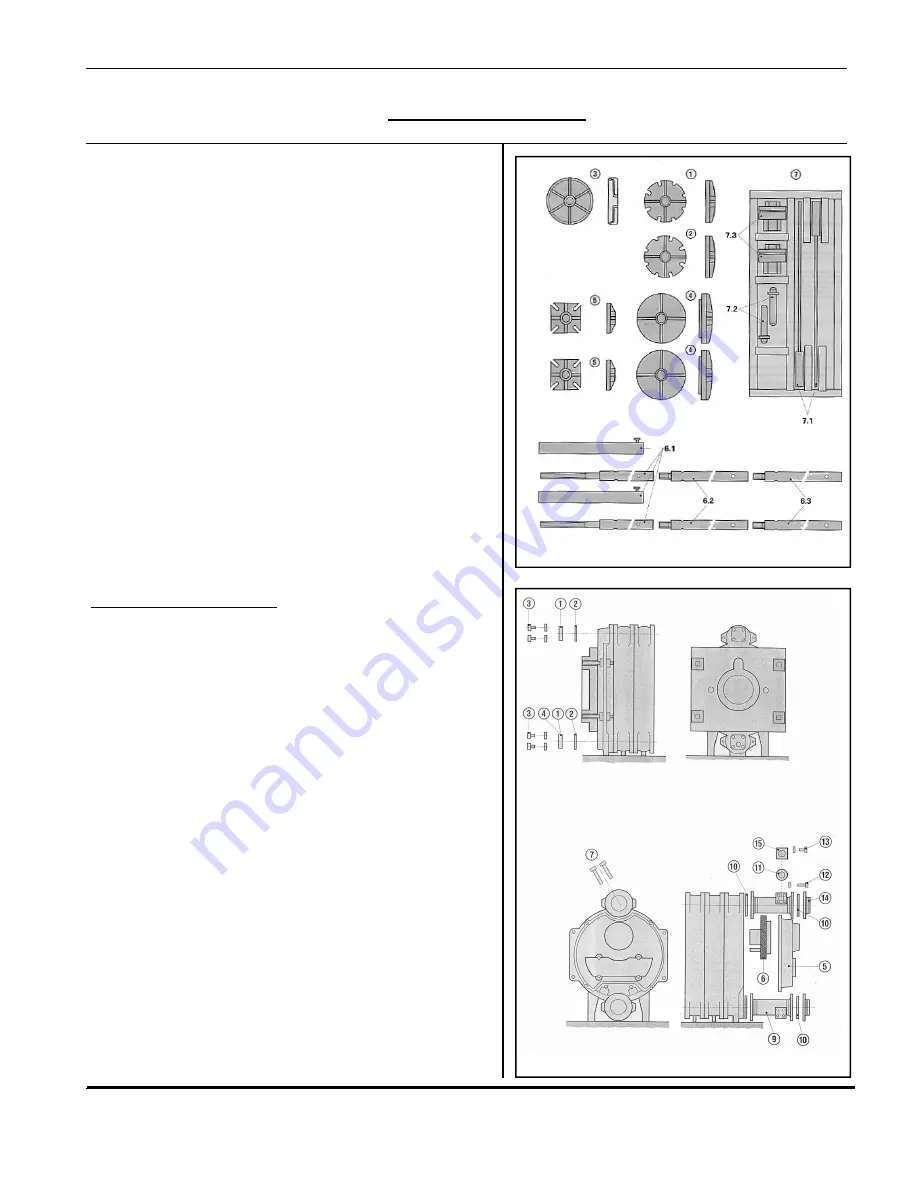

Pulling-up kit

Key:

1. Pulling-up

flange

at the top rear section

2. Pulling-up

flange

at

the bottom rear section

3.

Pulling tool for nipples

4.

Pulling-up flange for intermediate sections

5.

Pulling-up flange for front section

6.1 Basic

bar

6.2 Extension

bar

6.3 End

piece

bar

7. Case

containing

7.1 Free-running

ratchet

spanner

7.2 Stop

pins

7.3

Starting nut with thrust bearing.

Assembly of boiler connections

Legend:

1. Hexagonal screws M12 x 35

2. Supporting washer 13/24 x 2.5

3. Blank flanges 105

4. Rubber seal 95/61 x 5

5. Hexagonal screw M16 x 35

6. Flat washer 17/30 x 3

7. Blank flange 105

8. Rubber seal 207/196 x5

9. Rubber seal 95/61 x5

10. Flat washer 17/30 x3

11. Hexagonal nut M16

12. Hexagonal nut M16

13. Flat washer 17/30 x 3

14. Rubber seal 152/115 x 5

15. Weld neck flange NW 150, ND6

16. Hexagonal screw M16 x 60

17. Hexagonal screw M12 x 55

18. Blank flange 105 x 105, NW 65

19. Flat washer 13/24 x 2.5

20. Hexagonal nut M12

21. R½ plugs

A pressure test, as per RU1s instructions, should be carried out.

ASSEMBLY

INSTRUCTIONS

FOR:

RU 2S / BRU 2S

Fig.5.2

Fig.4.2

ASSEMBLY

INSTRUCTIONS

FOR:

RU

2S

/

BRU

2S

RU 2s Assembly