STREBEL CIS

ASSEMBLY INSTRUCTIONS FOR:

STREBEL CIS

Page 9

V.1-03.08

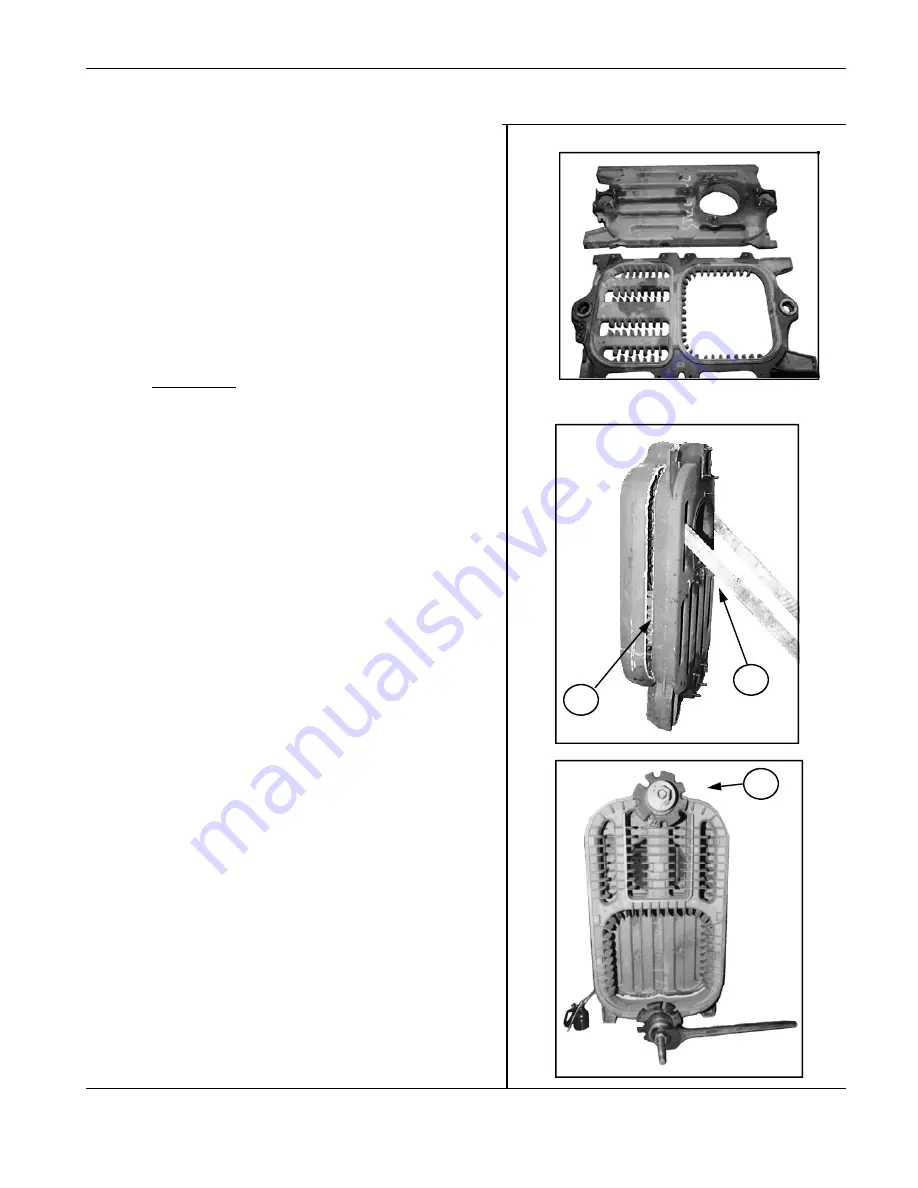

Assembly of the boiler block from individual sections

Starting with the rear section to the front, the boiler block is assembled on the

boiler base.

1. Erect and support the rear section (A).

2. Clean the rear section sealing grooves and place boiler mastic sealing strand

into the sealing grooves.

3. Clean nipple and port. Inspect and smear with nipple jointing oil

4. Drive nipple into flow and return ports

5. Level the first intermediate section onto both rear section nipples.

6. Pull on intermediate section with pulling up tool. Fix on pulling up flanges,

starting nuts and ratchet spanners; tighten the starting nuts evenly (C). The

clearance between the two sections must be equal when pulling-up. If

clearance is unequal insert a flat chisel in the narrower point and continue

pulling-up until clearance is equal again.

Avoid using

excessive force

and smooth out excess mastic.

Add on only one section at a time in each case.

Further sections are added accordingly.

7. On completion of the boiler block. Push pulling up bars through the lugs on

the ready assembled boiler block. Slide a flat washer and nut onto the tie

bars at the front and rear respectively and screw on hexagonal nut. Hold fast

one nut and draw on the other nut until tight.

Boiler Block Alignment

Any unevenness between boiler base and section feet can be levelled out by

laying metal shims underneath the boiler section feet.

A

B

C