S-CB

+

Boiler Range Manual

20

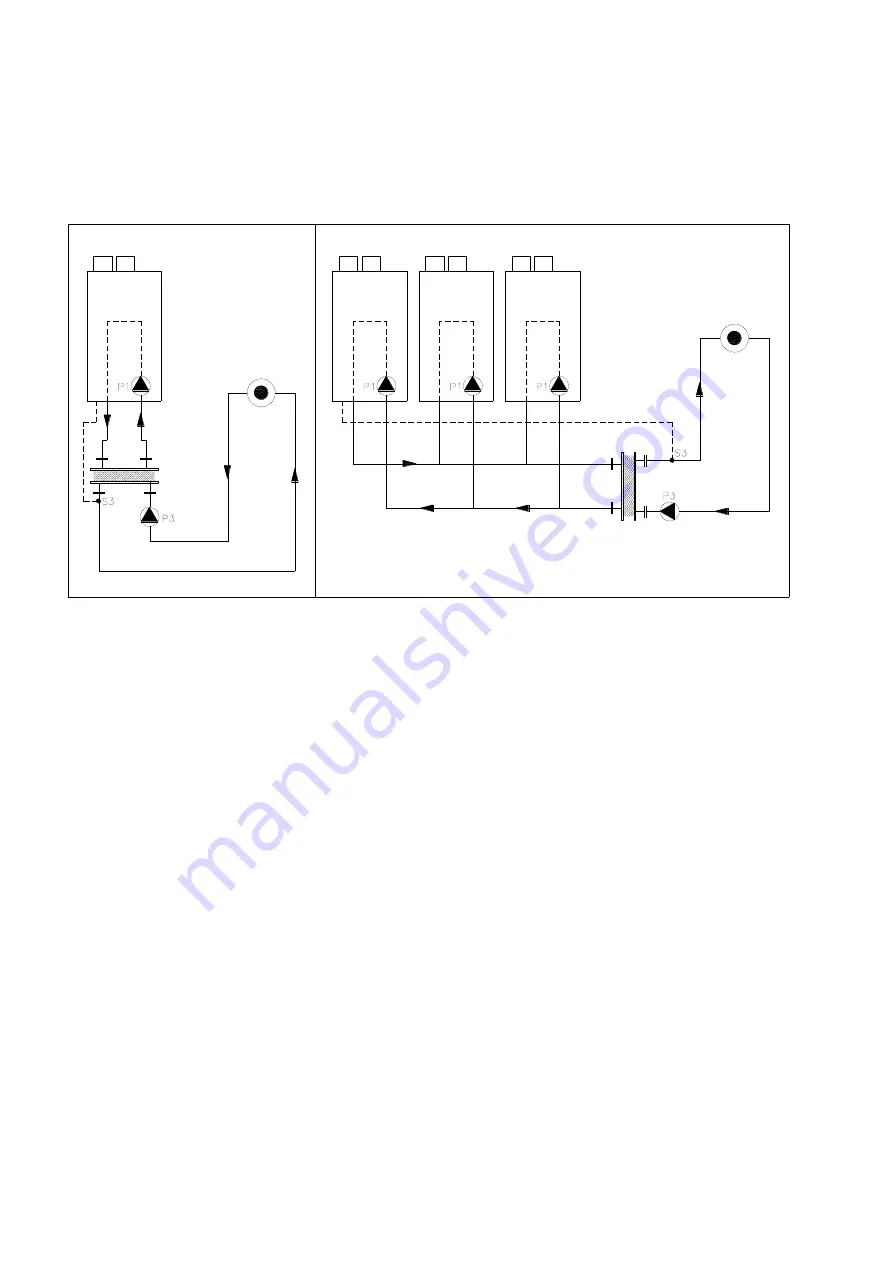

6.11 Plastic piping in the heating system

When plastic pipes are used in the central heating system, these should be separated from the boiler system by

using a plate heat exchanger. Diffusion (through the plastic) can cause air to enter the heating system. This could

damage the boiler, pumps and other components in the system. Be aware that plastic piping is often used in under

floor heating systems. When no measures have been taken to prevent the entrance of air into the boiler system,

the warranty of the boiler and any boiler part may be deemed invalid.

6.12 Automatic air vent

An automatic air vent is mounted on the boiler to remove the air from the water circuit.

NOTICE: This automatic air vent is only used for bleeding the air in the heat exchanger of the boiler. One or more

external automatic air vent(s) and/or air separators must always be mounted in the heating system to take out the

air trapped in the heating circuit.

DE-AERATION PROGRAM. When the unit is fired for the first time the unit starts a de-aeration program. One cycle

means 5 seconds pump running and 5 seconds pump off. A complete de-aeration program consists out of three

cycles. The de-aeration program can be interrupted/stopped by briefly pressing the service button.

6.13 Automatic water filling systems

When using an automatic water refill system some precautions should be taken (fresh water is bringing fresh oxy-

gen into the system), like installing a water meter to measure and evaluate the total water volume that is added to

the system. This to detect and eliminate any water leakage as soon as possible.

When an automatic water refill system is used, some form of logging should take place to prevent continuously

filling of the system with large amounts of oxygenated fresh water. This can happen when a leak in the system is

not detected and the total added water amount is not being logged.

6.14 Water pressure

First and for all, the installation should be designed and built conform all applicable regulations and standards, in-

cluding the right safety valves. IMPORTANT: Always keep the pressure in the boiler lower than the value at which

its safety valve opens.

Sensor

A water pressure sensor has been built into the boiler. With this sensor, the minimum water pressure in the boiler is

0,8 bar and the maximum pressure is 4,0 bar (sensor values). The normal water pressure is supposed to be be-

tween 1,5 and 2,0 bar.

The pressure sensor will stop the boiler from firing when the water pressure drops below 0,8 bar, and start the

boiler firing again when the water pressure reaches above the 1,0 bar. These values can be changed in the boiler

control settings.

BOILER

BOILER

BOILER

BOILER

HEATING

ZONE

HEATING

ZONE

PLATE HEAT EX-

CHANGER

PLATE HEAT

EXCHANGER

Summary of Contents for S-CB+ Series

Page 2: ......

Page 3: ......

Page 22: ...S CB Boiler Range Manual 22 ...

Page 39: ...S CB Boiler Range Manual 39 9 4Electrical schematics ...

Page 124: ...S CB Boiler Range Manual 124 ...