21

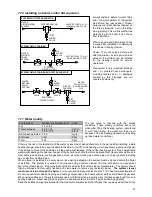

7.10 Installing a strainer and/or dirt separator

Always install a strainer (water filter)

and / or a dirt separator on the system

side after a low loss header / Strebel

boiler guard / plate heat exchanger on

the return pipework – not on the boiler

side (primary)! This will ensure that the

water going to the boiler is free of any

flow restrictions.

When using a water filter always check

a week after installation to determine

the strainer cleaning interval.

Advise to mount valves before and

after the strainer, including an air bleed

valve so the strainer can be isolated

for the heating system for service

operations.

Clean water is very important, blocked

and / or polluted heat exchangers,

including failures and / or damages

caused by this blockage are not

covered by warranty.

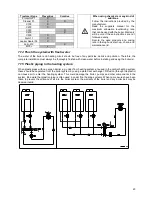

7.11 Water quality

The pH value is reached with the steady

conditions. These steady conditions will occur,

when after filling the heating system (pH around

7) with fresh water, the water will lose its air

because of the air bleeding operation and heating

up (dead water conditions).

If there is the risk of contamination of the water by any kind of debris/chemicals in the period after installing, a plate

heat exchanger should be used to separate the boiler circuit from the heating circuit (see drawing at the next page).

It is advised to prevent the possible air intake and water leakage of the central heating system. Fresh oxygenated

water might damage the heat exchanger of the boiler and should therefore be prevented! Usual spots where air is

most likely to seep in are: suction gaskets, pumps, air valve working as a venting pipe, O-rings / gaskets in stuffing

box, under floor heating pipes.

When a boiler is installed in a new system or an existing installation the system must be cleaned before the boiler

is installed. The system is required to be cleaned using a system cleaner from the list below or an equivalent

hydronic system cleaner. Follow the instructions provided by the system cleaner manufacturer. The system should

then be drained and thoroughly flushed with clean water to remove any residual cleaner.

The system cleaner

must never be run through the boiler.

For recommended cleaners see chapter "7.13 Chemical water treatment"

Do not use petroleum-based cleaning and sealing compounds in the boilers system as they could damage gaskets.

When using antifreeze in the system always use an inhibited mono propylene glycol antifreeze approved for use in

heating systems. Never use Ethylene glycol in a heating system as it is toxic and can damage gaskets.

Read the antifreeze suppliers manual for the maximum allowable level of antifreeze that can be used with the boiler.

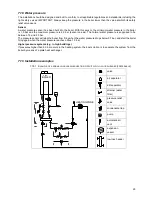

Contaminant

Maximum allowable level

Units

pH

7.5 to 9.5

Total hardness

50 to 150

CaCO

3

3.5 to 10.5

Clark

Aluminium particles < 0.2

mg/L

Chlorides

150

Ppm

TDS

350

Ppm

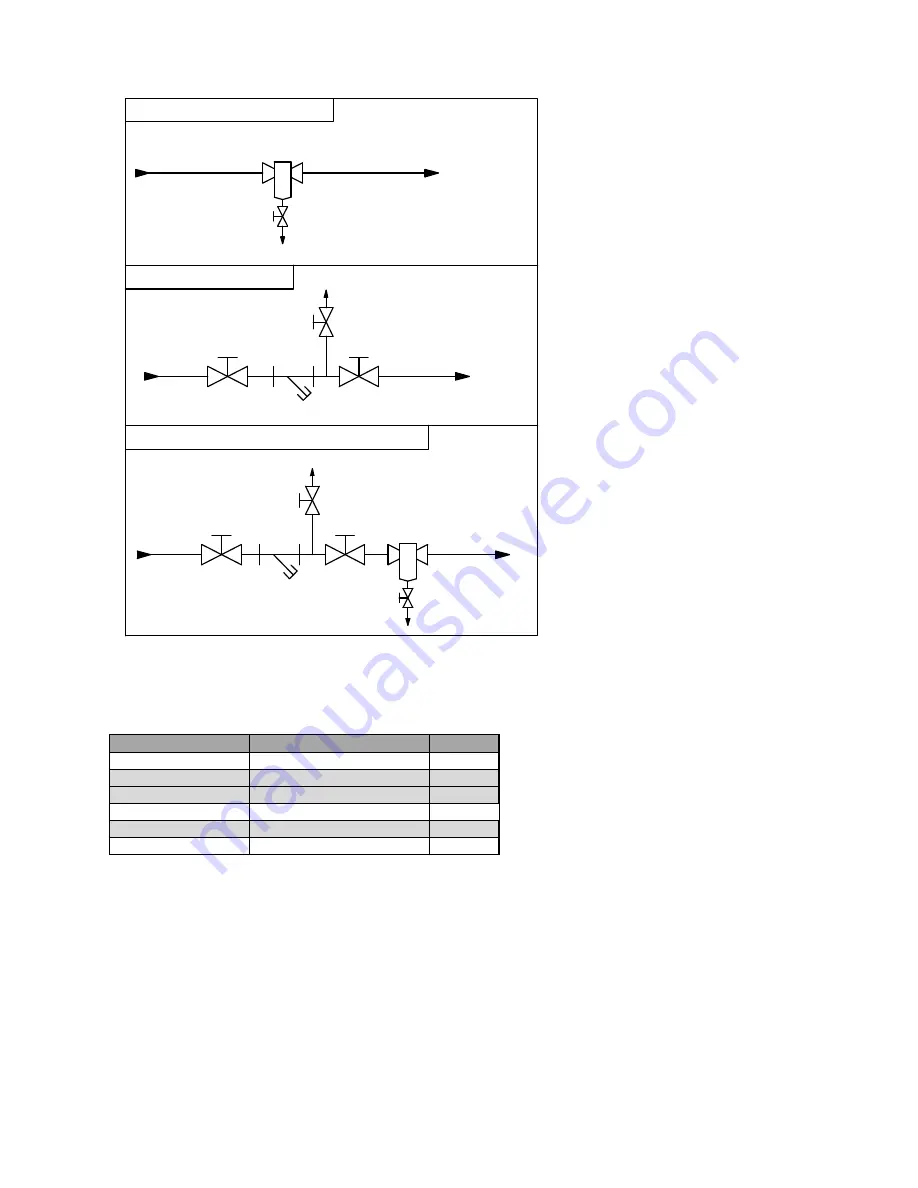

SYSTEM WITH DIRT SEPARATOR

SYSTEM WITH STRAINER

SYSTEM WITH STRAINER AND DIRT SEPARATOR

DIRT SEPARATOR

DIRT SE-

PARATOR

WATER

RETURN FROM

SYSTEM

WATER

RETURN

FROM

SYSTEM

WATER

RETURN

FROM

SYSTEM

WATER FLOW TO LLH /

BOILER GUARD / PHE

WATER FLOW TO LLH /

BOILER GUARD / PHE

WATER

FLOW TO LLH /

BOILER GUARD /

PHE

DIRT

BLEED

VALVE

DIRT

BLEED

VALVE

AIR

BLEED

VALVE

AIR

BLEED

VALVE

VALVE

VALVE

VALVE

VALVE

STRAINER

(WATER FILTER)

STRAINER

(WATER FILTER)

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......