30

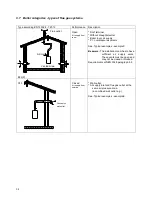

9 FLUE GAS AND AIR SUPPLY SYSTEM

9.1 General

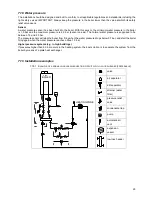

The boiler has a positive pressure flue system. For a single boiler, the available combined pressure drop for the

inlet and outlet system

is 200 Pa for the complete boiler range.

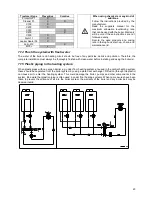

For a multiple boiler installation, always contact

the manufacturer for advice.

The S-CBX boiler is for either direct vent install or for installation using indoor combustion air, category IV, appliance

with sealed combustion requiring certain venting systems. All combustion air is drawn from outdoors or indoor. All

products of combustion are vented directly outdoors. The Vent, and if applicable Air-Intake piping, should be piped

to the outdoors. Under no conditions may this appliance vent gases into a masonry chimney. The internal safety

system shuts down the boiler in case the temperature of the flue gasses becomes too high, after which the appliance

will not run until re-started. Installations must comply with local requirements.

The front cover closes the housing air-tight making sure air is only supplied by the vent air intake. Therefore, make

sure the front cover always has been placed in its position during operation of the appliance.

Till a pressure of 200 Pa, power will remain the same. Bigger resistance causes power decrease.

Notice:

•

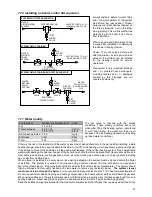

Install all horizontal flue components with an angle of 3° downwards in the direction of the boiler (roughly equal

to five centimetres for every linear meter). When not installed accordingly, it may result in condensate building-

up in the flue gas tube, eventually causing component failure.

•

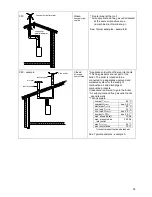

Wall flue terminals are generally used up to 80 kW. Using these terminals with larger capacities will give

unpleasant large condensate clouds.

•

When using a wall terminal, there is the possible risk of ice building-up on surrounding parts/structures,

because the condensate will freeze. This risk should be taken into account during the design phase of the

heating installation.

•

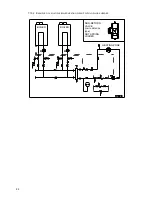

In line flue condensate drains

must

be used with flue runs longer than 4 meters with the condense drain pipe

going to a sewage system.

•

Because the flue gases can have a low temperature, the boiler needs to have a high efficiency approved

stainless steel or plastic flue system. These materials, including the gaskets, should be usable for positive

pressure flue gas systems and have a temperature class of

T120. Meaning: the parts must be certified for

use at temperatures of minimal 120 °C

(See also warnings below).

Note:

In general, water heaters are certified with their own flue gas material. The water heater must be provided with high

efficiency SS or PP flue gas components available. The parts have to be qualified for a overpressure class P1 or

H1 and a temperature class of T120 minimum.

For flue gas type B23, C13, C33, C43, C83 systems, use only flue gas and air supply parts of the approved

supplier.

Before installing, read the installation manual(s) of the supplier of the flue gas and air supply parts

included with the parts. Manuals for parts supplied can be found at:

Warning:

Never use aluminium containing flue gas pipes in these boilers.

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......