65

The error log screen will show on the first line: Boiler ID for which boiler the error was detected (cascade system

only), Error Code, (internal) Error Number, Error Type (Lockout/Blocking).

The second line will show the Error Description.

The bottom line will show the Time Stamp (date and time) when the error was detected (in the format as

configured in the Date Time Settings menu), and also the selected error index from the total number of errors in

the (filtered) error log. Only Time Stamp, Code and Description is displayed.

Example see picture above.

A014 = Error code.

(14) = Error Number (tracking number, 1-15 errors are stored maximum).

Lockout = Error type.

Air Switch Not Closed = Error description.

Wed 04-11-2018 14:50 = Time stamp when the error occurred.

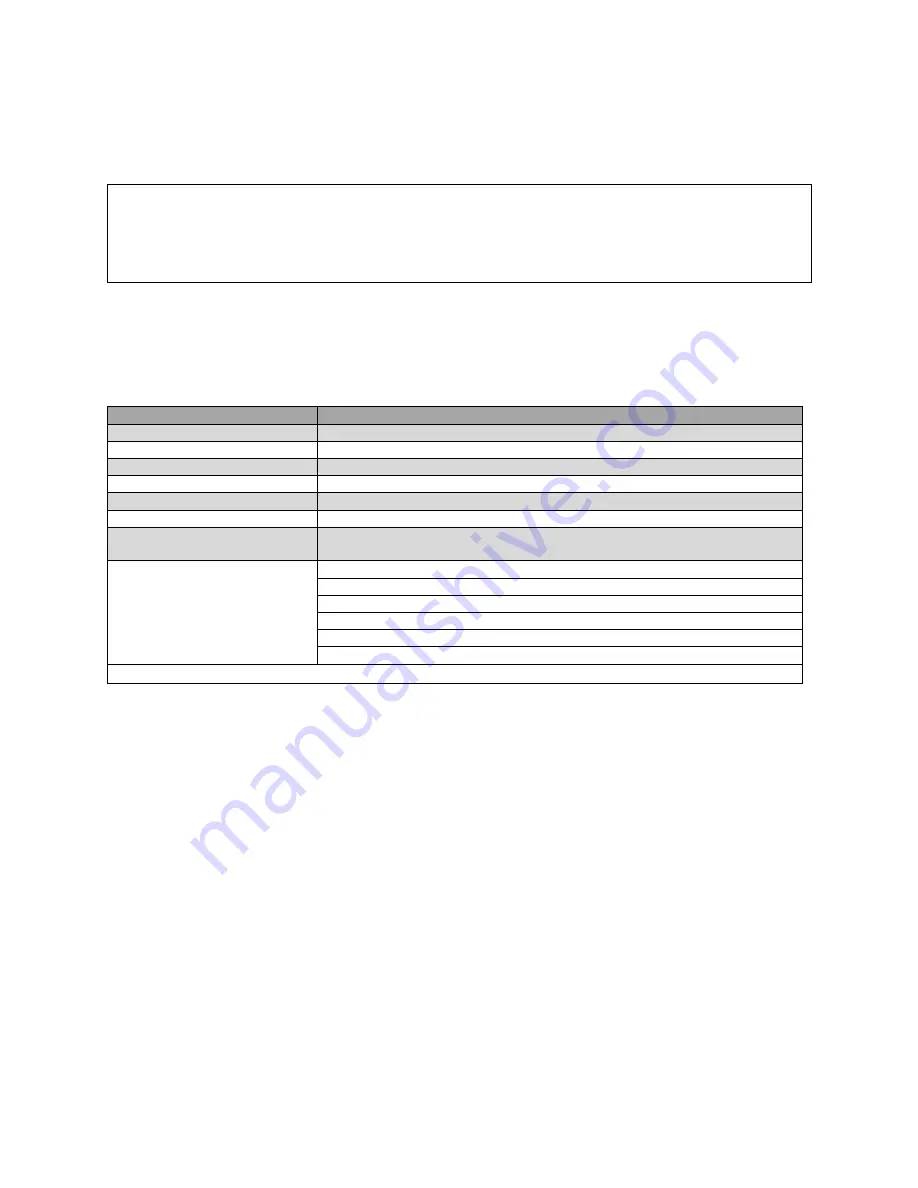

12.5 General

The burner controller is designed to function as a standalone control unit for intermittent operation on heating

appliances with a premix (modulating) burner and a pneumatic air-gas system.

Fuses

Mains input 1 x 5AT, 230V

Flame establishing period

2 seconds

Safety time

5 seconds

Ignition attempts

3

Pre-purge time

≥ 2…60 seconds (not safety critical)

Pre-ignition time

2 seconds (not safety critical)

Flame failure response time

< 1.0 second

Flame-current

Minimum

1.0 μA

Start-detection 1.5 μA

Cable length AL-BUS

1

mm

2

(AWG) Cable length m (ft)

0.25 (23) 100 (328.1 ft)

0.5 (20) 200 (656.2 ft)

0.75 (18) 300 (984.3 ft)

1.0 (17) 400 (1312.3 ft)

1.5 (15) 600 (1968.5 ft)

1) This is the total length of the cable, not the length between two boilers. The length differs with the diameter of the cable.

12.5.1 P

UMP START EXERCISE EVERY

24

HOURS

To protect the pump from getting stuck at a certain position it is forced to run for 10 seconds every 24 hours. This

is done only for the boiler loop pump at the start-up of the board.

12.5.2 F

ROST PROTECTION

The Frost protection function protects the boiler and boiler loop from freezing.

The T_Supply, T_Supply_2 and T_Return sensors are checked for generating a Frost protection demand.

• When any of the sensors drop below FP_Start_Pump the boiler loop pump is switched ON for CH.

• When any of the sensors drop below FP_Start_Burn the boiler is fired.

• When all of the sensors measure above FP_Stop the Frost protection demand is ended.

When the demand for Frost protection is ended the pumps will post-circulate for CH_Post_Pump_Period.

Parameters are factory set

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......