76

12.8.5 A

NTI

-

LEGIONELLA PROTECTION

Anti-Legionella protection is enabled for DHW modes with an external tank with a sensor (DHW Mode 1) or for the

direct fired water heater (DHW Mode 6 & 7) and when DHW is not switched OFF.

To prevent legionella a special function is implemented in the software.

• When DHW Mode 1 is selected the Anti-Legionella protection will be checked on the T_DHW_Out sensor.

• When DHW Mode 7 is selected the Anti-Legionella protection will be checked on the T_Supply sensor.

• When DHW Mode 6 is selected the Anti-Legionella protection will be checked on the Top_Store_1 sensor. This

sensor will be named the Anti_Legionella_Sensor in the remaining part of the explanation.

At least once every 168 hours (7 days) the Anti_Legionella_Sensor must reach a temperature above

Anti_Legionella_Setpoint for a time specified by Anti_Legionella_Burn_Time.

If 7 days have passed and these conditions are not met, the boiler is forced to heat-up the system for Anti-Legionella.

When the Anti_Legionella_Sensor temperature is below Anti_Legionella_Setpoint the control switches ON the

pumps, when the Anti_Legionella_Sensor temperature is above Anti_Legionella_Setpoint 5 °C (41 °F) the control

stops the pumps.

When DHW Mode 1 is selected the boiler setpoint will be at Anti_Legionella_Se DHW_Store_Supply_Extra,

for DHW Mode 6 and DHW Mode 7 the burner setpoint will be at Anti_Legionella_Setpoint.

If the supply temperature drops below the Boiler_Setpoint the boiler is started as well. The boiler is PID controlled

towards the Boiler_Setpoint. When the supply temperature rises above boiler se DHW_Supp_Hysterese_Up

the boiler is switched OFF.

When the Anti_Legionella_Sensor is above Anti_Legionella_Setpoint 3 °C (37 °F) for Anti_Legionella_Burn_Time

the controller goes into post circulation and ends the Anti-Legionella demand. When the controller has powered up,

the Anti_Legionella_Sensor temperature must reach a temperature of Anti_Legionella_Setpoint (for

Anti_Legionella_Burn_Time) within 2 hours, otherwise the boiler is forced into Anti-Legionella demand.

Every time an Anti-Legionella demand has ended the Anti_Legionella_Active_Counter is incremented to indicate

how many Anti- Legionella actions have been performed. Also, the Anti Legionella Wait Time is started to delay the

next anti legionella cycle.

This diagnostic tool can also override the wait time for Anti-Legionella. When this demand is forced the timer will be

set to 0 and Anti-Legionella demand will start immediately. Then the demand must be completed successfully before

the wait timer is set again.

The anti-legionella demand has priority over any DHW and CH demand. However, when the anti-legionella

protection is active and there is no heat or burn demand because the Anti_Legionella_Sensor is already at a high

enough temperature CH/DHW demand will be accepted as normal.

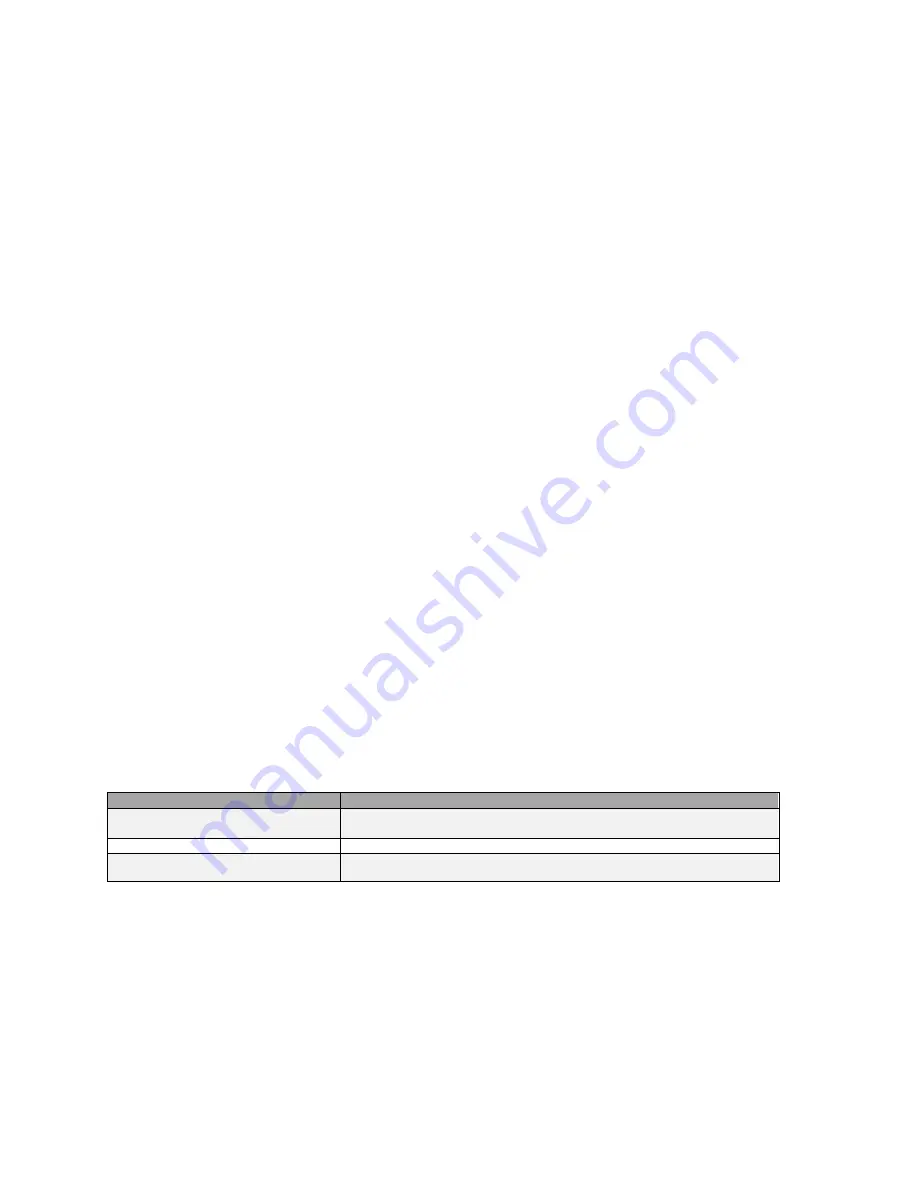

Parameters are factory set

Parameter

Factory Setting.

Anti_Legionella_Setpoint

Setpoint for Anti-Legionella demand

60 ºC (140 ºF)

Anti_Legionella_Burn_Time

30 Min.

Anti_Legionella_Wait_Time

Wait time for Anti-Legionella demand.

120 min after cold start, 168 h after first successful Anti-Legionella demand

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......