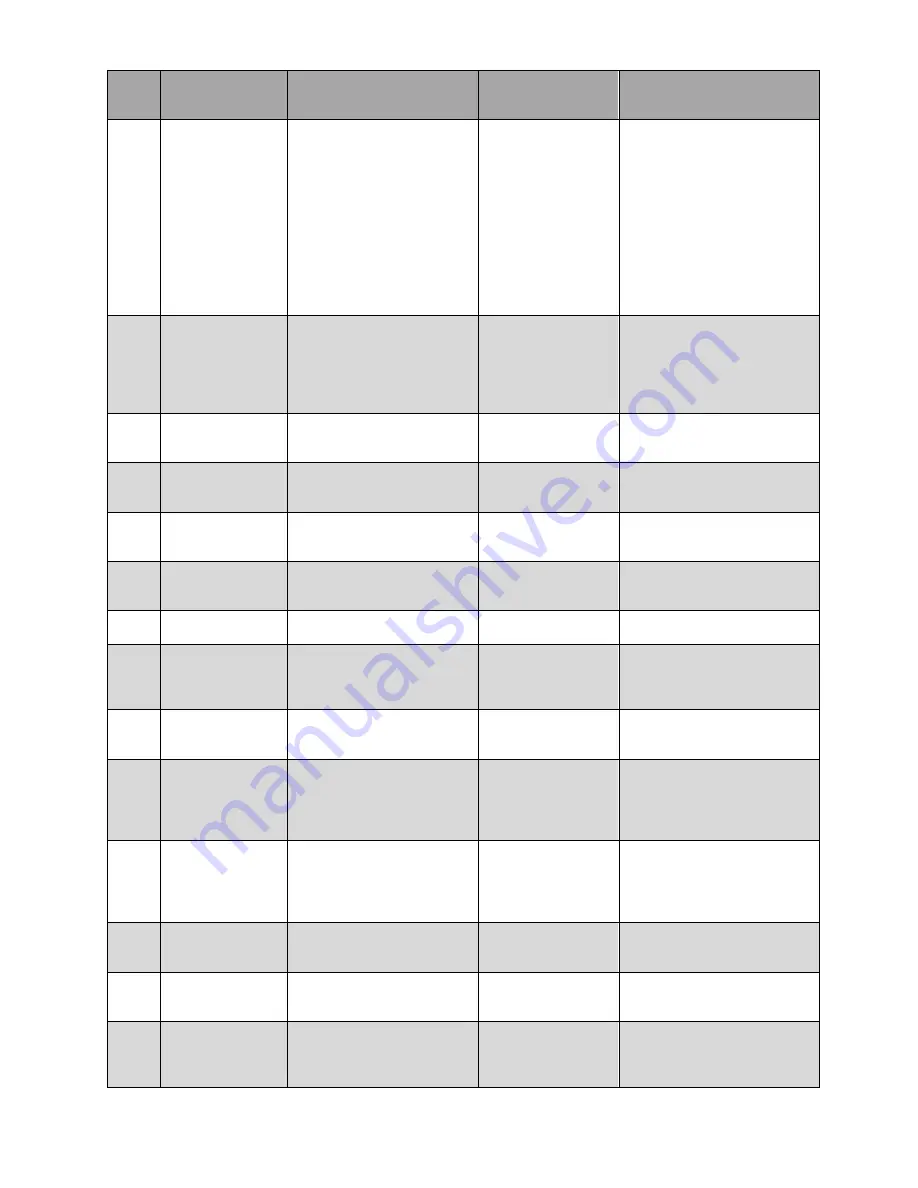

87

Lock

out

code

Error

Description

Cause

Solving

15

MAX_TEMP_

ERROR

The external overheat

protection is enabled or the

T_Supply sensor measures

a temp. of over

Prot_Overheat_Temp -

SGOverheat_Duplex_Toler

ance for a period of

Max_Value_Period

Burner door clixon

tripped because of

overheating of the

burner door or the

water flow is

restricted, or back

wall thermal fuse

has tripped

because back wall

target refractory is

damaged or

is broken.

Check burner door gasket

and replace burner door

gasket and reset clixon on

burner door or check pump

and waterflow and replace

pump or increase water flow

check also if valves are

closed or check if rear wall

fuse is broken if so replace

and also replace backwall

combustion chamber target

refractory.

16

FLUE_GAS_

ERROR

Flue temperature exceeded

the maximum flue

temperature

There is no water in

the heat exchanger

or flue gas sensor

is malfunctioning or

heat exchanger is

overheated.

Check if flue sensor is

working correctly if not so

replace flue sensor. Check

waterflow if to low increase

waterflow.

17

STACK_ERROR Internal software error

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

18

INSTRUCTION_

ERROR

Internal software error

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

19

ION_CHECK_

FAILED

Internal software error

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

20

FLAME_OUT_

TOO_LATE

Flame still present 10

seconds after closing the

gas valve

wrong earthing of

PCB and boiler

Check earthing of PCB and

boiler

21

FLAME_BEFOR

E_IGNIT

Flame is detected before

ignition

wrong earthing of

PCB and boiler

Check earthing of PCB and

boiler

22

TOO_MANY_

FLAME_LOSS

Three time flame lost during

1 demand

bad gas supply or

CO2 level is not

correct or bad

ignition rod

check gas supply pressure,

check CO2 level and adjust if

necessary, replace ignition

rod or replace ignition cable.

23

CORRUPTED_

ERROR_NR

Error code RAM byte was

corrupted to an unknown

error code.

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

27

FILLING_TOO_

MUCH

Too many automated filling

attempts in a short time

period

If output is

programmed as

filing valve and

there are to many

filing attempts

Check if there is a leak in the

central heating system or if

the boiler it self is leaking

also check expansion vessel

on internal leak

28

FILL_TIME_

ERROR

Filling takes too long

If output is

programmed as

filing valve and

filling takes more

than 10 minutes

Check if there is a leak in the

central heating system or if

the boiler it self is leaking

also check expansion vessel

on internal leak

29

PSM_ERROR

Internal software error

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

30

REGISTER_

ERROR

Internal software error

wrongly

programmed PCB

or PB

reset PCB or replace PCB

and or display unit

32

T_EXCHANGE_

DIFF_ERROR

The 2 exchange sensors

deviate too much for more

than 60 seconds

There is not not

enough water flow

through the heat

exchanger

Check if the general pump is

running and if all valves are

open to make enough flow

Summary of Contents for S-CBX 105

Page 2: ......

Page 40: ...40 9 10 Flue Terminal Positioning ...

Page 42: ...42 9 11 1 FIGURE 12 LINE G ...

Page 55: ...55 11 5 Ladder Logic Diagram ...

Page 56: ...56 11 6 Electrical schematics ...

Page 57: ...57 ...

Page 137: ......